Shut off valve replacement

on the 1992 300D (OM602)

by pdrayton

6/9/07

Shut off valve replacement W124 OM602 & OM603 300D 2.5

I had my shut off valve fail and my car not shut off with the key and I couldn't find any info on how to replace the valve either in the forum or in the FSM.

Anyway, I tackled the job today, and got it done. Not the easiest job in the world - but not difficult, just a little weird. It's really just a matter of not thinking it's a case of pulling the old one out and putting the new one in.

What you really have to do is pull off a lot of other stuff, find the extra hidden bonus bolt and then do some other stuff and then pull it out. It's not that bad really - it sounds harder than it is. It would probably take me 30 minutes if I had to do it again. Anyway, enough blabber, here's the spiel...

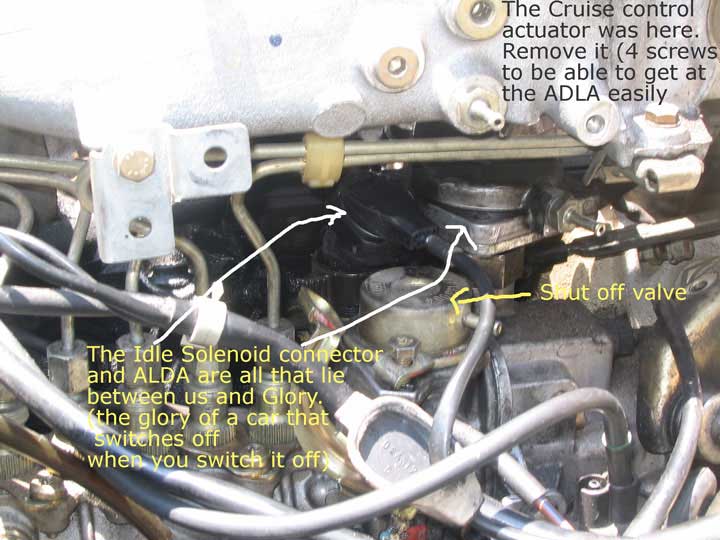

1.Remove the idle servo connector. That's the black plastic connector just behind the vacuum shut off valve. It has to be removed to get the shut off valve (SOV) out. To get the plastic connector out, pull the plastic tab on the lower ring towards you (counter-clockwise). It should turn about 1/4 turn and release the top part of the connector which can now be wiggled out. Remove the Cruise control actuator first (big gold thing on the exhaust intake)

Now we remove the ALDA so we can get at the back bolt of the SOV (yes, I know - SOV sounds like something else doesn't it! ). To remove the ALDA I twisted the entire body of the ALDA using channel locks, while holding the locknut at it's base with a crescent wrench. Turn the ALDA anticlockwise. It only takes a 1/4 turn to loosen it and then it's easy pickings to get it out. Also a great time to adjust the ALDA if your car is sluggish, or if you are not a moron who drives with his foot on the floor the whole time.

Now that they're both out the way, we're on easy street. Sort of....

EDIT: DO NOT REMOVE THE STOP LEVER or circlip holding the stop lever shaft in the IP - it is not necessary, and it can make you put the lever in the wrong place. I thought it was necessary, and had pictures etc about it in the first version of this post. But it is not necessary, in fact, it can screw things up. I did this, and spent the whole day trying to figure out why my car had no power, the EDS said air sensor error, and the car was a total dog, even when I rigged the turbo to work manually. What's happened is you've put the shaft of the SOV in the wrong place and it is messing with the throttle. The proper way to get the old valve out is to push the stop lever all the way down (in the stop position) and then gently pull and wiggle the SOV out at the angle shown in the pic below - ie leaning backwards. It will then slide out of the connector to the stop lever. Have a look in there when you've got it out and you'll see what I mean. The new valve shaft then will slide in at the same angle and mate with the stop lever.

When I put the SOV in the wrong way, the stop lever moved with the throttle. So if that happens to you, you know you've got it in wrong.

So ignore the bits below about removing the circlip (if you don't see them then it is becuase I have deleted them).

Now you can wiggle the SOV out of the IP. Note that the thumb twist ring thing that held the idle solenoid electrical connector in place, might get in the way a bit. Sort of push it out the way with a screw driver (that's what I did - gently) to get the lip of the SOV past it. Leaning the SOV backwards and pushing the stop lever down, will allow the SOV to disconnect from the stop lever.

All done. Rinse and Repeat. Um... I mean..... installation is the reverse of removal. Be sure to look down inside the IP and see where the stop lever goes to. Move the stop lever and see the piece of metal with a strip cut out of it move up and down. That cut out strip is where the nib at the end of the SOV fits into. NOt above, or below, but right into it. If you put it above or below, you risk a car that doesn't run, or a runaway diesel. See below

VERY IMPORTANT: I'm not sure if it can happen with the 602/3 but with other's such as the 616/7, if you install the SOV wrong you can end up with a 'run away' diesel. If you don't know what that is, look it up. Basically, bad. Very bad. Mucho bad.

To avoid a run away diesel, test the SOV you just installed by applying vacuum to it. The shutoff lever should go all the way down to horizontal. Check it is all the way down and that you can't press it down anymore by hand. If that is the case, you are probably OK. Just to be 100% safe, I took the cross over tube off and got a piece of wood ready to put over the intake in case it did the runaway thing. It didn't, but better safe than sorry (my mother taught me that).

Hope that helped.

Paul

KEYWORDS (for poor beggars searching for this stuff): Vacuum Shutoff valve, vacuum shut off valve, engine stop unit, 603, 602 W124 300D 2.5, won't shut off.

Discuss this DIY here.

-pdrayton

CategoryDiy