For less than US$20 just about anyone can build an alarm that will let you know your engine's oil pressure is getting dangerously low. It may alert you to a problem before your engine is ruined. This alarm is designed to screw into a tapped hole in the cover of a Mercedes diesel oil filter canister but could be used in other cars with similar designs. You can also tee into the line to the mechanical oil pressure gauge in some models. It will not work in an engine using a screw-on oil filter unless you can find another place for the oil pressure switch.

I have deliberately kept this design simple and with an absolute minimum in parts so that it is easy to build and inexpensive to buy. It is not a perfect design; there are many ways to make this alarm more useful, more complicated, and more expensive. You may wish to make your own modifications.

The design does not look at either boost or engine RPMs (to see if the engine is above idle and therefore should have "good" oil pressure). This helps keeps it simple and makes it applicable to NA engines and older models without a tachometer (or newer ones with a broken tach).

The alarm activates when oil pressure drops below 1 bar (15 psi). This is lower than most of us would like. For an engine turning 3000 RPM at freeway speeds, an alarm ought to go off if the oil pressure drops below 30 or 40 psi. Without making the system more complicated (by monitoring engine speed or something) I can't do that.

One of the challenges in the Mercedes oil pressure gauge is that it sits at 3+ bars and never moves, except at idle. A gauge that never moves is a gauge that doesn't get watched. If you don't happen to see the gauge suddenly drop (because your oil pump just failed, for example), you won't know until the engine starts making bad noises. Catching a failure at 1 bar may be good enough to prevent serious engine damage.

The alarm has three parts: a bright red flashing LED, a resistor, and a Volkswagen oil pressure switch. It does not have a buzzer but one could be added. The LED is very bright; it should be visible even during daylight and absolutely cannot be missed at night. Here is the parts list:

1. Oil pressure switch, 1.0 bar, VW part number 068 919 081, about $10. This switch was used in Volkswagen TDIs during the 1990s. The one I bought tested at 13 psi. If your engine has a true hot idle oil pressure greater than 20 psi then you may wish to use the 1.4 bar version of this same switch. I found that with the 1.4 bar switch on my engine the alarm would always go off at hot idle so I changed to the 1.0 bar version. Warning: Do not rely upon the oil pressure gauge in your dash as it may be in error. Use a high-quality mechanical gauge to get the true idle oil pressure.

2. Blinking red LED, Radio Shack part number 276-312, about $2.

3. Resistor, 1000 Ohms (also called "1K Ohms"), 1 Watt, Radio Shack part number 271-153 or equivalent, pack of two, about US$1.50. You will need both of the resistors in the pack.

You will also need a 1/8 inch pipe tap and the appropriate drill to make a pilot hole (11/32 inch is good, 5/16 inch will do). A tap handle will make it easier to tap the threads straight but you can use an adjustable wrench if need be. Any good hardware store will have these items. Finally, you will need some wire, wire connectors, tape or shrink tubing for insulation, a female spade terminal, and some Teflon tape for the oil pressure switch.

Under the hood

Begin by removing the cover from your oil filter canister. You can do this project as part of an oil change if you wish; but as long as the engine is OFF, there won't be any pressure in the canister even with the sump full. Because the cover has ribs on the inside, you must drill your 11/32 or 5/16 inch hole from the inside out to miss the ribs. (This was mentioned in another thread over a year ago by Diesel911.)

If you don't want to booger up your shiny like-new cover, buy an extra from a forum member parting out an engine and put the good one away. Before you enter your car in the next

concours d'elegance, put the shiny cover back.

Next, put Teflon(R) tape on the threads of the oil pressure switch and screw it into the cover. The 10 mm threads of the switch are not the same as the 1/8 inch pipe threads you made in the cover but they're close. Don't use too much Teflon tape -- you need metal to metal contact between the switch and the cover to ground the circuit. Use a circuit test light or ohmmeter to make sure there is continuity between the body of the switch and the cover. NOTE to

experten: Even if you have the proper 10x1.0 mm Metric tap, don't use it. The cover isn't completely flat and the crush washer on the switch won't seal.

Put the cover back onto the oil filter housing. Don't forget the o-ring and make sure you didn't leave any metal chips in the cover. Now put the spade connector on the wire and push the spade connector onto the switch, then run the wire into the passenger compartment through any convenient hole. Start the engine and make sure you don't have any leaks; you're now finished in the engine bay.

In the driver's seat

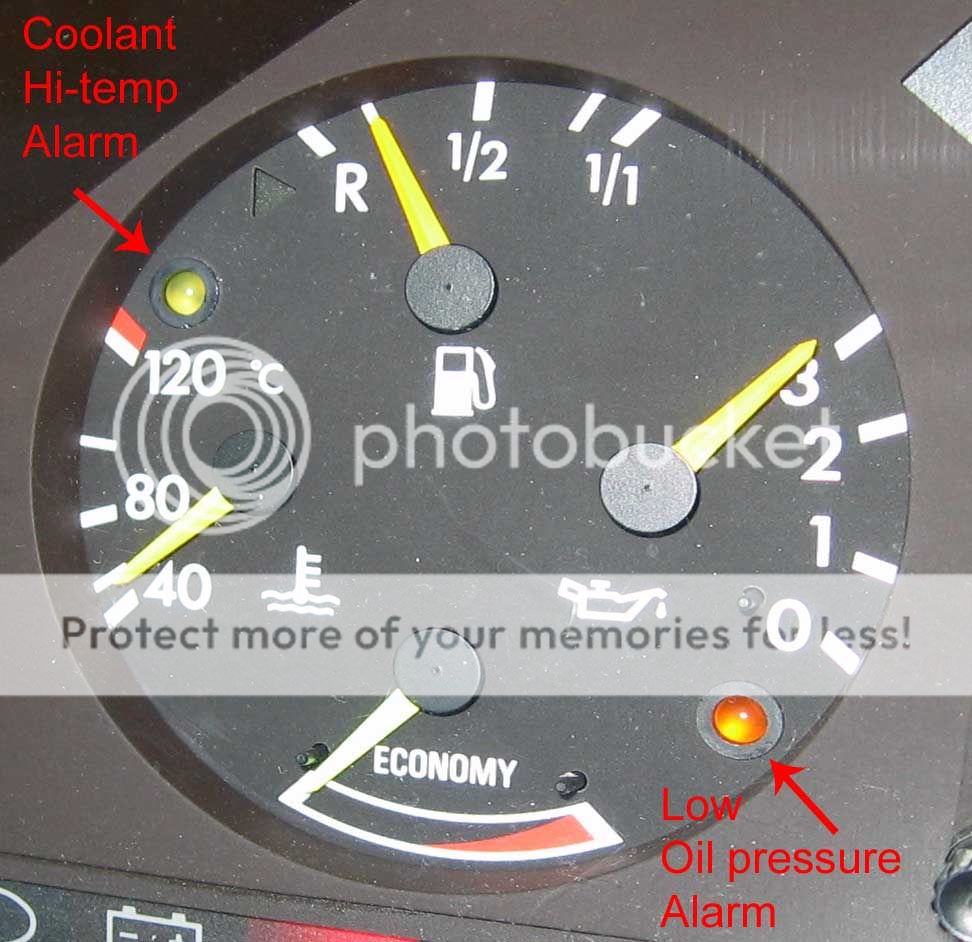

You will want to put the LED where it will point straight at your eyes when you are driving. It is not bright enough to be dangerous but bright enough that you will not miss it when it blinks at you. (The LED is made of clear plastic but the light is red.) I installed my LED in the instrument cluster next to the oil pressure gauge. This is not recommended for beginners as there isn't a lot of working room and you could damage something expensive. Here's what it looks like (I didn't use the Radio Shack LEDs).

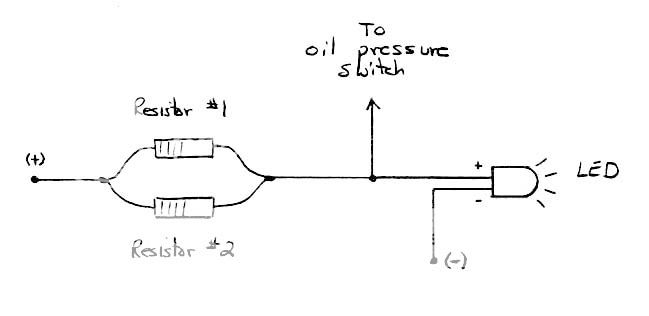

The following diagram shows how to wire the LED and the resistors to the oil pressure switch. Notice that the resistors are in parallel so the effective resistance is 500 Ohms and the power handling capacity is 2 Watts. This is necessary because of the way the switch works: it opens the circuit when it sees low oil pressure. A close-on-low switch would have been more convenient but we have to work with what we have.

When the oil pressure in your engine is above 1 bar (15 psi), as it should be, the oil pressure switch closes and shorts out the LED so it cannot blink. Current will still flow through the resistors and they will get a little warm to the touch but not hot. The current is only about 30 milliamps at 14 Volts, less than a medium-sized bulb would use, and it does this only when the engine is running, so there's no need to worry about the battery. When the LED is blinking the circuit uses even less current

The following is a note on polarity. If you wire the LED backwards it won't work. The resistors don't care, they have no polarity.

Connect the components as shown in the diagram. Insulate the connections with tape or shrink tubing. You may add a 1 Amp fuse to the wire marked (+) if you wish but it really isn't necessary. Connect the wire marked (+) to anything that has 12 Volts when the ignition switch is in "position 2" (pre-glow or engine running). Connect the wire marked (-) to any convenient chassis ground. That finishes building the alarm.

Using the alarm

When you turn the key on in pre-glow, the LED will blink until you crank the engine, it starts, and the oil pressure comes up. Then the LED will go out. You may consider this a "self-test" of the alarm.

If the LED starts to blink while you are driving, it means that the oil pressure has apparently fallen below 1 bar (15 psi). Check your oil pressure gauge. Is it below where you are used to seeing it? If it is safe to do so, turn the engine off immediately and coast to a stop. Remember that without the engine you will not have power-assisted steering and the vacuum-assisted brakes will last for only a couple of pushes on the pedal, then you will have to press much harder. Otherwise, stop as soon as it's safe and shut the engine off.

OTOH, if the oil pressure gauge says everything is OK, you get to ask yourself, "Do I feel lucky?" Remember that if the oil pressure gauge sender or its wire fails, the gauge may say 3 bars all the time. IMHO this is a design failure. Oh well. If the oil pressure switch fails or if its wire breaks, the LED will flash. This is a form of "fail-safe."

That's all there is. I will add additional posts to this thread with "options" (complications, really): keeping the alarm off until the engine starts, adding a buzzer, and adding a mechanical oil pressure gauge.

Enjoy and be safe!

Jeremy