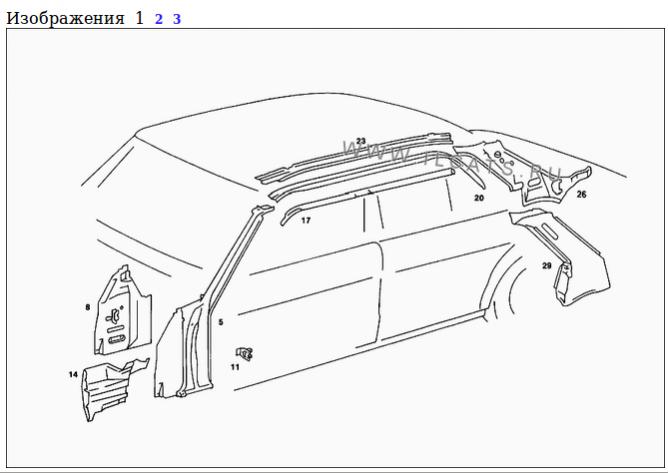

I've been looking at the structure of how it has been put together.

I'm not entirely sure if the roof together with the middle door pillars were fitted together first, but the middle door pillar and the outer sill definitely were spot welded together first before the spot welds between the lower edge of the outer sill and the floor pan were fixed.

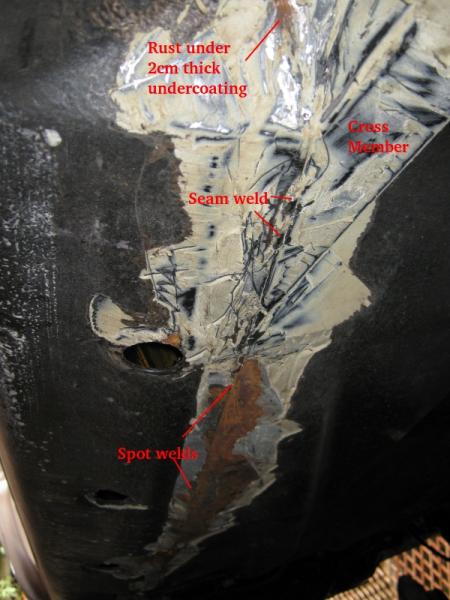

The spot welds on the floor pan and outer sill joint were never treated to a coat of seal sealer. Which means that if the inside of the car gets wet then the floor pan not only rusts through in one place but the water travels along the whole joint as shown in this picture I posted previously

I consider this to be a design fault!