Remove the B3 brake drum from the centre planetary assembly if you have not already done so.

Fit the sun gear onto the intermediate shaft.

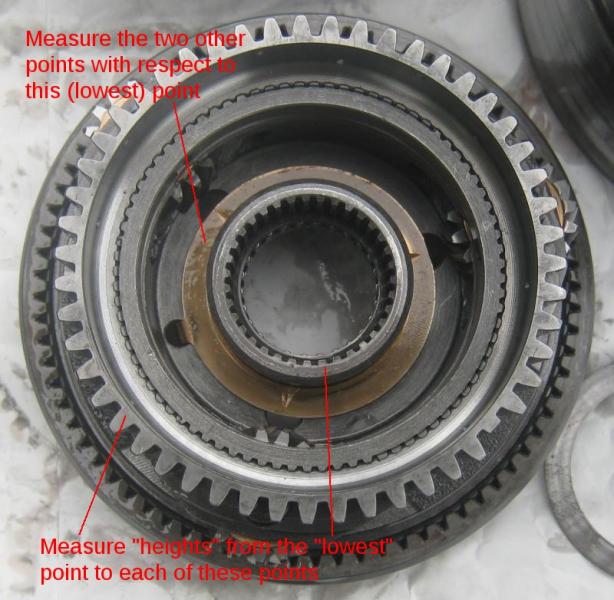

Measure dimension “a” from the top of the centre sun and planet assembly (the planet part which is going to be fitted into the B3 brake drum) to where the thrust washer will be fitted.

ATSG recommends that you position the thrust washer prior to making this measurement. I found these measurements to be pretty tricky mainly because the foot on my depth gauge was too wide... in my work around I found that the thrust washer got in the way. I'll continue the explanation as though I used the correct tools! Here's a photo showing it again to make it as clear as possible.

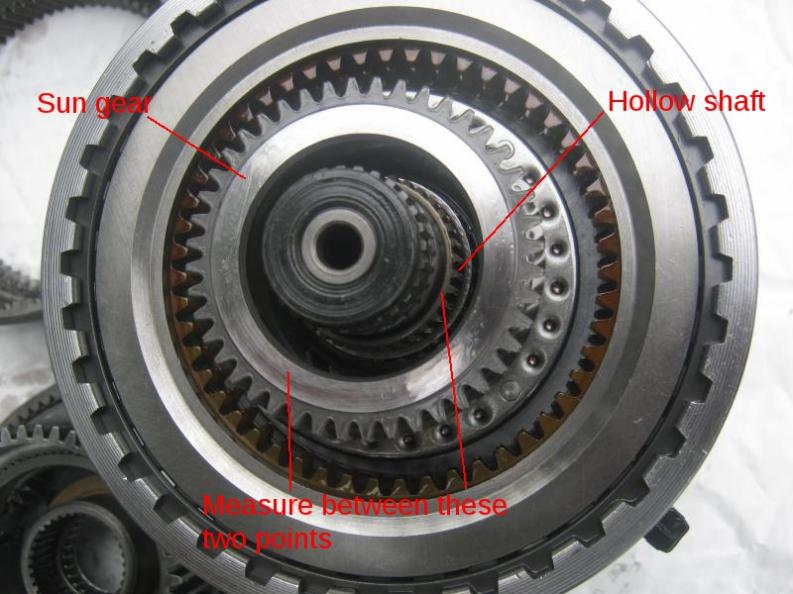

Next measure “b” from the top of the centre sun and planet assembly to the shoulder of assembly that goes over the hollow shaft.

Calculate value “c” by subtracting “b” from “a” (c = a-b).

Next measure “d” by measuring from the upper surface of the sun gear to the shoulder of the hollow shaft (that encases the intermediate shaft)

Calculate end play S by subtracting “d” from “c” (S=c-d). The end play on this side of the sun and planet system should be between 0.2 and 0.3mm.

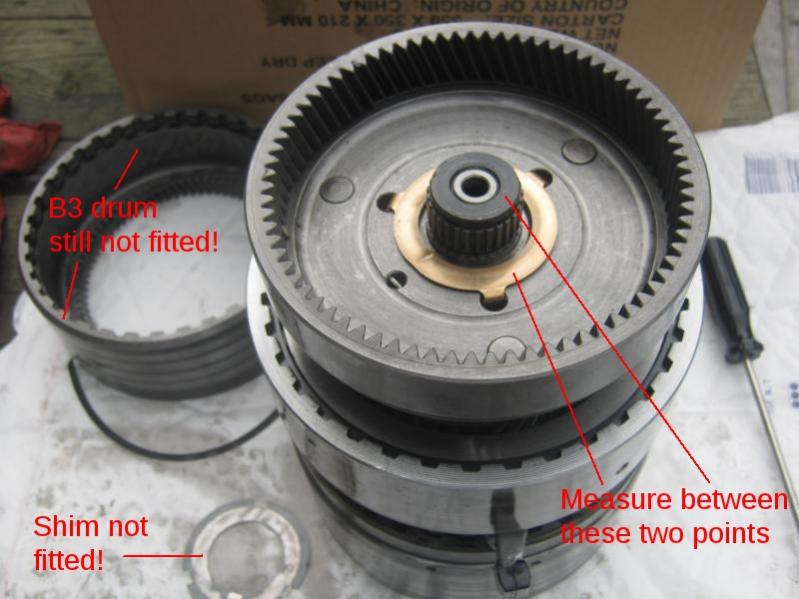

To adjust the end play you need to change the shims. Once you are sure that the end play is correct use a bit of grease to hold it in place and fit the planetary part without the B1 brake drum onto the rest of the gear set.

Now you need to measure the clearance on the other side.

This is where a dedicated transmission stand would be handy - due to budget restrictions I placed a roll of tape under the gear set to push the intermediate shaft into position.

If you have a small foot on your depth gauge you will be able to measure the distance “a” from the top of the intermediate shaft to the shoulder on the intermediate shaft.

Measure “b” from the top of the intermediate shaft to the top of the thrust washer.

This second clearance is calculated by subtracting “a” from “b” (S=b-a).

Again this value should be between 0.2 and 0.3mm. This clearance is adjusted by shims.

I had a bit of a nightmare checking these clearance values – partly because my depth gauge was a bit too big and chunky for the job. I found it very easy to convince myself that the Mercedes technician who had built the transmission was obviously a daft monkey and that I needed several 10mm thick shims to get the clearance anyway near to the ball park figure.

Unsurprisingly this turned out to be utter nonsense.

If you think you need a shim bigger than 0.1mm I would check your measurements again and again... think about it... it probably isn't going to wear that much if anything at all... if the clearance was set that badly from new the transmission wouldn't have made it once round the block...