Quote:

Originally Posted by t walgamuth

Great patina! Looking very good! I am jealous of the progress as mine is stalled out at present. My builder is stymied by the wiring harness on my Mercedes steering column.

On the insulation, I'd be concerned about the smoke generated in case of a fire. Did you try burning some of that material you used? Where is that product designed to be used on a building?

|

Yes, it is very frustrating when a project gets stalled. In your case, the unique and super cool truck will be well worth the wait.

MB wiring is "different!" Figuring out wiring and switches by methodically testing with an ohm meter is very time consuming.

I checked specs on the Peel & Seal roofing product before using. It has a UL Class “A” Fire Rating which if defined as “effective against severe fire exposure.”

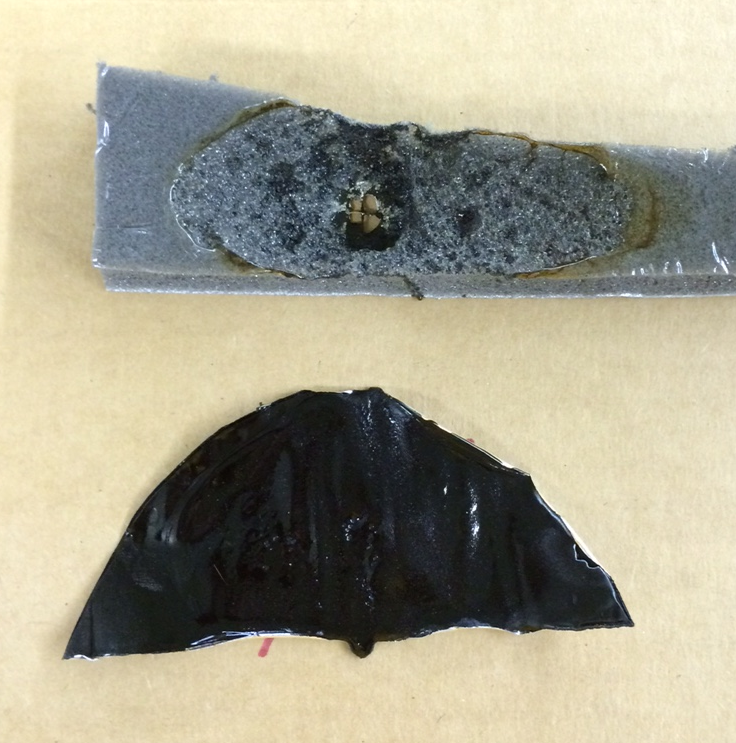

Had not thought much about smoke. So this morning I did the burn test you suggested. Peel and Seal will burn with a propane torch flame directly on the back side, but it is a slow burn and stops as soon as the torch is removed. Takes a few seconds to even get a flame. Not much smoke.

Not so with Dynamat under hood liner (which I used to cut down on the bucket of bolts noise)! Tested it as well. Burns quickly with lots of smoke. Pic below (placed on cardboard for the pic, after they had cooled!)

In comparison, I had the flame on the Peel & Seal much longer than on the Dynamat. Dynamat inside insulation products are much different that their under hood liner, however.

I'm much more concerned about smoke from wiring inside the cab than from the insulation. I had a 3' commercial Chinese wire with alligator clips for a ground when testing a wiper motor. Had a 15 amp fuse on the hot side. The Chinese wire overheated and filled the shop with acrid smoke.