|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

LinkBack | Thread Tools | Display Modes |

|

#16

|

||||

|

||||

|

Thanks for the plug welding input - I'll see how I get on with my plan first.

I want to be able to make good quality bead welded butt joints so I can plug up holes in body panels with new metal. That needs to be done whatever I choose to do with spot welds / plug welds.

__________________

1992 W201 190E 1.8 171,000 km - Daily driver 1981 W123 300D ~ 100,000 miles / 160,000 km - project car stripped to the bone 1965 Land Rover Series 2a Station Wagon CIS recovery therapy! 1961 Volvo PV544 Bare metal rat rod-ish thing I'm here to chat about cars and to help others - I'm not here "to always be right" like an internet warrior Don't leave that there - I'll take it to bits! |

|

#17

|

||||

|

||||

|

FYI

Quote:

How To (Plug Weld) For Auto Body Collision Repair Work - *Collision Repair Technology Program* - YouTube Floor Pan - plug welding - YouTube Plug Weld Complete - YouTube 1971 Olds "S71" Plug / Spotwelding Tips V8TV - YouTube Structural Plug Weld Destructive Testing - YouTube Weld testing and apprenticeship training - YouTube |

|

#18

|

||||

|

||||

|

Thanks for the links - there aren't many places like Stoke on Trent College anymore... perhaps it is time for a move back to the UK...

__________________

1992 W201 190E 1.8 171,000 km - Daily driver 1981 W123 300D ~ 100,000 miles / 160,000 km - project car stripped to the bone 1965 Land Rover Series 2a Station Wagon CIS recovery therapy! 1961 Volvo PV544 Bare metal rat rod-ish thing I'm here to chat about cars and to help others - I'm not here "to always be right" like an internet warrior Don't leave that there - I'll take it to bits! |

|

#19

|

||||

|

||||

|

I'm looking into something like this - I'll let you know if I get anywhere...

__________________

1992 W201 190E 1.8 171,000 km - Daily driver 1981 W123 300D ~ 100,000 miles / 160,000 km - project car stripped to the bone 1965 Land Rover Series 2a Station Wagon CIS recovery therapy! 1961 Volvo PV544 Bare metal rat rod-ish thing I'm here to chat about cars and to help others - I'm not here "to always be right" like an internet warrior Don't leave that there - I'll take it to bits! |

|

#20

|

||||

|

||||

|

I'm struggling

Yes - still struggling.

I've been laying down beads this morning trying to get the desired (((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((( effect... It takes a steady hand. Sometimes it seems like I've just had a heavy night on the juice and by hand is trying to do the jitterbug. Still I'm almost there:-  Like I said my hand isn't really steady. I'm trying to slow myself down to the right pace. It looks like I'm doing OK to start off - but as the electrode gets shorter I start to race a bit. You can see how some of the beads below are wider on the left (at the beginning of the bead - I'm right handed and thus start from the left and go right) and a bit thinner on the right - towards the end. You can also see that I sometimes seem to get worried after starting the bead and jump a bit. There are blobs at the start of the run - I think what I'm doing wrong there is waiting too long before continuing. Before cleaning up it looks like a continuous bead - but it turns out to be a lump of slag between dot and bead.

__________________

1992 W201 190E 1.8 171,000 km - Daily driver 1981 W123 300D ~ 100,000 miles / 160,000 km - project car stripped to the bone 1965 Land Rover Series 2a Station Wagon CIS recovery therapy! 1961 Volvo PV544 Bare metal rat rod-ish thing I'm here to chat about cars and to help others - I'm not here "to always be right" like an internet warrior Don't leave that there - I'll take it to bits! |

|

#21

|

||||

|

||||

|

Some answers to questions that I had before (but didn't ask!)

Question:- How wide should the bead be after welding?

Answer:- About one and a half times the width of your electrode Question:- How far should you make the arc jump from the surface you are welding to the tip of the electrode? Answer:- About the same distance as the diameter of your electrode (more to come when I remember them)

__________________

1992 W201 190E 1.8 171,000 km - Daily driver 1981 W123 300D ~ 100,000 miles / 160,000 km - project car stripped to the bone 1965 Land Rover Series 2a Station Wagon CIS recovery therapy! 1961 Volvo PV544 Bare metal rat rod-ish thing I'm here to chat about cars and to help others - I'm not here "to always be right" like an internet warrior Don't leave that there - I'll take it to bits! |

|

#22

|

|||

|

|||

|

The practice runs you are making are good for welding thicker plate. When welding sheetmetal you will never make one long continuous bead. 3/4 of an inch max between tacks otherwise you will burn through and cause a lot of heat distortion.

|

|

#23

|

||||

|

||||

|

I may have the answer for that!

^

After a bit of internet research I've come up with the following:- 1) Welding with 7014 1.6mm rods is easier - you just can't buy them anywhere! 2) This English company (oh yes the English do it again!) have a tungsten rod that looks like the dog's doo dah... Techweld I'm currently chasing down 7014s and those 1mm tungsten beauties that probably cost more than a house for a set of ten... ...to be continued...

__________________

1992 W201 190E 1.8 171,000 km - Daily driver 1981 W123 300D ~ 100,000 miles / 160,000 km - project car stripped to the bone 1965 Land Rover Series 2a Station Wagon CIS recovery therapy! 1961 Volvo PV544 Bare metal rat rod-ish thing I'm here to chat about cars and to help others - I'm not here "to always be right" like an internet warrior Don't leave that there - I'll take it to bits! Last edited by Stretch; 12-22-2011 at 09:20 AM. Reason: Can't spell |

|

#24

|

||||

|

||||

|

Found some good links here

Marine engineering student in the UK Marine Engineering Training: May 2011 A nice lap joint  From here Welding | decipher... A horror story here Thomas's World: The Secret of Steel: Arc Welding Thin (0.02") Sheet Metal And the best to last:- Arc (MMA) Welding Flat Joints And same site - some nice videos here Arc Tutorial - Rod Position, Motion, and Technique

__________________

1992 W201 190E 1.8 171,000 km - Daily driver 1981 W123 300D ~ 100,000 miles / 160,000 km - project car stripped to the bone 1965 Land Rover Series 2a Station Wagon CIS recovery therapy! 1961 Volvo PV544 Bare metal rat rod-ish thing I'm here to chat about cars and to help others - I'm not here "to always be right" like an internet warrior Don't leave that there - I'll take it to bits! |

|

#25

|

||||

|

||||

|

And my progress? Well I've run out of unbuggered metal and it is raining...

__________________

1992 W201 190E 1.8 171,000 km - Daily driver 1981 W123 300D ~ 100,000 miles / 160,000 km - project car stripped to the bone 1965 Land Rover Series 2a Station Wagon CIS recovery therapy! 1961 Volvo PV544 Bare metal rat rod-ish thing I'm here to chat about cars and to help others - I'm not here "to always be right" like an internet warrior Don't leave that there - I'll take it to bits! |

|

#26

|

|||

|

|||

|

The lap joint pictured above looks a hell of a lot like tig welded aluminum. There is no way a lowly stick or mig welder will achieve a weld like that. I wish I could TIG weld!

|

|

#27

|

||||

|

||||

|

Compared with the cost of a decent MIG welder a starter TIG welder seems within reach - only I don't know if you'd be getting value for money at the lower TIG end... the nicest looking TIG sets with AC/DC and a gas bottle and all the bits seem to come in at about 2500 euros over here... whereas a new generation arc set will set you back between 200 and 500 euros (MOSFET amp and anti-stick etc etc)... there is some value in learning to use an arc welder. Whether or not I can convince you or not remains to be seen!

__________________

1992 W201 190E 1.8 171,000 km - Daily driver 1981 W123 300D ~ 100,000 miles / 160,000 km - project car stripped to the bone 1965 Land Rover Series 2a Station Wagon CIS recovery therapy! 1961 Volvo PV544 Bare metal rat rod-ish thing I'm here to chat about cars and to help others - I'm not here "to always be right" like an internet warrior Don't leave that there - I'll take it to bits! |

|

#28

|

||||

|

||||

|

Post Christmas rush between the rain

After several days of Christmas related delays to the progress of learning to weld I got 30 minutes in this afternoon before the drizzle got too wet (you want to keep your rods dry!)

Me did a butt weld in one go - Mungo would be proud of me... ...yeah OK so I blew a hole in it too - if it stops raining I'll pop back outside and see if I can correct my mistake. I guess that is also an important part of welding => rectifying mistakes. If it all works out well I'll post up a picture of the correction - if not I'll not mention it again...  See the wet looking patches? That's proof of rain that is. I think I'm still trying to run before I can walk - doing a butt weld and all - as I think I need to get the stitching weave a bit neater. Still once in a while you need to do something a bit different instead of yet another bead...

__________________

1992 W201 190E 1.8 171,000 km - Daily driver 1981 W123 300D ~ 100,000 miles / 160,000 km - project car stripped to the bone 1965 Land Rover Series 2a Station Wagon CIS recovery therapy! 1961 Volvo PV544 Bare metal rat rod-ish thing I'm here to chat about cars and to help others - I'm not here "to always be right" like an internet warrior Don't leave that there - I'll take it to bits! |

|

#29

|

||||

|

||||

|

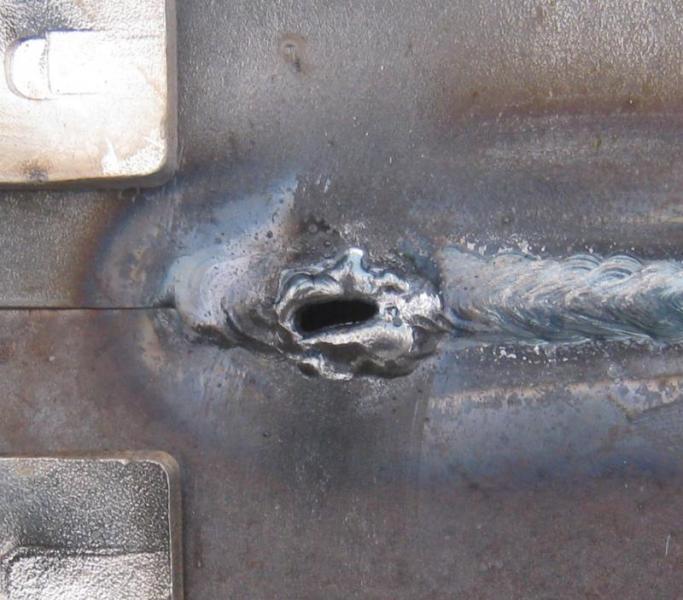

Filling a hole!

I just about pulled it off - hole was filled. It took several goes welding around the edge / welding over the hole to do it.

I cleaned up each attempt with ye olde angle grinder and wire brush attachment before adding a new layer - remember whilst you can get slag to spark it melts at a higher temperature than steel! You need to remove it first... In the end I got this  Just a tiny bit of slag inclusion in the shiny bit that has been ground away (this time angle grinder and grinding disk) to make sure I've got solid metal as a joint. Not too bad - I wouldn't leave it like that on a car though: could be a stress point or a start of a crack... so I conclude I'm not good enough to weld nuclear reactors yet... or my W123.

__________________

1992 W201 190E 1.8 171,000 km - Daily driver 1981 W123 300D ~ 100,000 miles / 160,000 km - project car stripped to the bone 1965 Land Rover Series 2a Station Wagon CIS recovery therapy! 1961 Volvo PV544 Bare metal rat rod-ish thing I'm here to chat about cars and to help others - I'm not here "to always be right" like an internet warrior Don't leave that there - I'll take it to bits! |

|

#30

|

||||

|

||||

|

Next learning point =>

Sinking weld pools!

I think I've got the current set too high. Look at this =>  This has happened a couple of times to me now. It is really quite a strange experience. The electrode is kind of moving along as you'd expect it to - this sounds like an outer body experience and in a way it is! I'm concentrating with my eyes to make sure the spark is the right length, whilst kind of letting my arm deal with the weave or stitching effect as well as the progress from left to right along the butt joint. So for me anyway eyes are kind of the more conscious part of the process... You can see the spark working as it should - melting the metal - nice deeper red coloured weld pool of molten metal - brighter yellow molten slag around it... ...when all of a sudden the healthy spark kind of splutters and the whole process stalls. This happens with a kind of more hollow sounding change in sound. Before you get to this stage; the welding process sounds more like it is a ringing sound on tight metal but as the weld sinks the sound changes to the hollow sound. If you ignore it and don't stop you get a hole (see previous 2 posts). This time I stopped in time to get the effect you can see above. This is what it looks like on the underside

__________________

1992 W201 190E 1.8 171,000 km - Daily driver 1981 W123 300D ~ 100,000 miles / 160,000 km - project car stripped to the bone 1965 Land Rover Series 2a Station Wagon CIS recovery therapy! 1961 Volvo PV544 Bare metal rat rod-ish thing I'm here to chat about cars and to help others - I'm not here "to always be right" like an internet warrior Don't leave that there - I'll take it to bits! |

|

| Bookmarks |

|

|