|

|

|

|

|

|

|

|

|

|

|

#166

|

||||

|

||||

|

X 2 on the "Actual" OP

Our Mercedes OP Gauge is more of a "representation" of an OP Gauge.

FYI the Engine (And OP sender) in the pictures is Sans Chassis... (I have a Deceased OM602 ,for illustration purposes only) I believe You'll be most happy going at the OP sender from the "TopSide" of the EC. Jeremy, Mplafleur in this post says the 300SDL has a 12mm by 1.5 twist on it: Oil Pressure sender nipple size & Thread size? (AND MB LOVES to use the same Sender on everything) EDIT: [O.K. the OP sender part # 0065429417 is used on all the 61X and 60X series motors]

__________________

'84 300SD sold 124.128 Last edited by compress ignite; 02-11-2010 at 11:14 AM. |

|

#167

|

|||

|

|||

|

One member drilled and tapped the top of his oil filter cover to place his pressure sensor. I did not see anything particuarily detrimental in doing so.

Just watch the position of the intergral support web on the underside of the cover before drilling. You can easily restore it to normal with a plug or by grabbing another cover off a wreck. Keeps the mass of parts low to eliminate constant vibration stress. I resisted the thought of any form of a christmas tree type of arrangement off a tee for this reason. Although there is really not enough mass to matter I suspect. Yet the moment arm is increased and would have to be factored in. The awkward position of the existing sensor especially was not encouraging either. Nicest thing about the top cover is just removing it. Drilling and threading the hole with no problem at all with the chip mess to deal with. Install the sensor and back on it goes. Do not forget you can also perhaps use the transmission interlock as well as an additional add on to avoid any random buzz before getting into gear. Congratulations as you are obviously moving along with this and your ideal is very cost effective. Last edited by barry123400; 02-11-2010 at 10:49 AM. |

|

#168

|

|||

|

|||

|

I wonder if oil pressure at the top of the filter is the same as at the factory oil sender location? All the data points that we have are from the normal sender location...

__________________

80 300SD (129k mi) 82 240D stick (193k mi)77 240D auto - stick to be (153k mi) 85 380SL (145k mi) 89 BMW 535i 82 Diesel Rabbit Pickup (374k mi) 91 Jetta IDI Diesel (155k mi) 81 VW Rabbit Convertible Diesel 70 Triumph Spitfire Mk III (63kmi)66 Triumph TR4a IRS (90k mi)67 Ford F-100 (??) |

|

#169

|

|||

|

|||

|

Quote:

It could even work a little in your favour. Enough to be of any benifit is questionable. Any delay in dropping oil pressure because of the filter delay for practical purposes should be meaningless. I suspect a few seconds at worse. Maybe less. There is a bypass option in the filter that possibly opens up with little differential pressure as well. Others more knowledgeable will hopefully add their thoughts. Many will be interested how this works out for you. I know I am. As for myself. Just have not got time yet to go locate a junk washing machine level sensor to experiment with. I am also very interested in the exhaust pressure present at say idle and 1500 rpms. The 603 engines have a test port that could be utilised. On the 616 or 617 a hole may have to be drilled and threaded into the exhaust manifold. Because of the heat I would want to extend the distance between that point and any actual sensor a good distance.. I know there is little fume flow up the line as the sensor is a dead end. Sooting of the line or fitting hopefully will not be an issue either. This approach is only if the boost pressure use proves impractable. This will have to be looked at as well for those natural aspired 616 and 617 engines anyways. Your ideal will not work well on tired engines and there are a lot of them out there. All my four diesel mercedes engines are in very good condition. It is always dangerous to mention this as something will then occur. This is more circumstance than luck. Cars in the north accumulate far fewer miles on average over the same cars in warmer climates. Rust will usually in fact kill them well before major engine wear problems develop. There will always be exceptions though. Last edited by barry123400; 02-11-2010 at 12:07 PM. |

|

#170

|

||||

|

||||

|

OP sensor installation location

I like the idea of using the top of the oil filter housing. I've seen the idea mentioned here but have resisted because I like to keep the engine as stock in appearance as possible and stuff sticking out of the oil filter housing will stand out like a sore thumb. But it is hard to ignore the fact that the cover is an easy item to access and that means it will get done much sooner. I have family here for the weekend so it will have to wait until next week but at least I can start collecting fittings. I'll use stainless in the filter cover as it will blend in with the cover a little better (color-wise) than brass.

I'll have to hunt for a spare cover; junkyard 603s are rare out here, in fact I've never seen one. Does the 602 take the same cover? I know the 61x engines use a different cover as do the 606s. People with 'tired' engines will have to use an 0.9 bar switch. Somewhat riskier but still better than nothing. It would be nice if an adjustable pressure switch suitable for hot oil could be found. Then you could set it to whatever works best for you. My VW 1.4 bar switch did not show up yesterday as expected, I'll have to call Smothers and see what has happened. Jeremy

__________________

"Buster" in the '95 Our all-Diesel family 1996 E300D (W210) . .338,000 miles Wife's car 2005 E320 CDI . . 113,000 miles My car Santa Rosa population 176,762 (2022) Total. . . . . . . . . . . . 627,762 "Oh lord won't you buy me a Mercedes Benz." -- Janis Joplin, October 1, 1970 |

|

#171

|

||||

|

||||

|

More progress and a snag

Got the VW 1.4 bar pressure switch today. It's marked (stamped into the metal) "1.2 -- 1.6 bar." I tested it with air pressure from my compressor (less messy than oil!) and two different pressure gauges. Both show that the switch trips at 1.4 bar (20 psi) which is perfect for me.

The snag is that the switch is "closed" (conducts electricity) when the pressure is above 1.4 bar and is "open" when the pressure drops below 1.4 bar. I had thought that it was the other was 'round so my circuit design is wrong. I'll have to add a relay or something. Lemme think about it for a couple of days. In the meantime, here are some "serving suggestion" photos I took a few minutes ago. The photos show the switch and a mechanical oil pressure gauge tee'd together and placed in the engine compartment of my '87 300D Turbo (W124, OM603). There's a space on the left (driver's) side, in between the ABS pump and the blue flying saucer. I plan to drill/tap the oil filter cover and run a 1/8 inch plastic line (inside an outer covering for safety) to the gauge/switch. (I couldn't find stainless fittings, had to buy brass.) NOTES 1. In some models, the alarm horn is here; mine has been removed. 2. The gauge will actually be mounted a little lower; in the photo the gauge is just propped up and would be hit when the hood is closed. 3. You can screw the switch directly into the oil filter cover, you don't need to have the gauge. It's just something I want to do. 4. Other model cars will have a different configuration but the same basic idea should work. THREADS 1. The VW oil pressure switch is Metric; the threads are M10x1.0 (10mm straight threads) - machine screw threads, not tapered pipe threads. The switch has an aluminum washer that does the sealing. If you plan to put the VW switch directly in the oil filter cover, use an M10x1.0 machine tap. 2. 1/8 inch British Standard Pipe (B.S.P.) thread is very close to 10mm. If you use American or UK fittings as I show in my pictures, they will be tapered pipe thread, 1/8"-28. The metric-threaded VW switch will go into a 1/8 BSP tapped hole but only a few threads. Put some Teflon tape on the threads and screw it into the tee as far as it will go. Be gentle. Don't try to force it in all the way to the washer, it will break or strip the threads. You can also try re-tapping one leg of the brass tee with an M10x1.0 tap if you happen to have one. I may try that if I can find a single tap (my set lacks that size). No, I won't be able to see the pressure gauge while I'm driving, will I? But I will be able to see it when I'm playing under the hood. Since it reads much higher than 3 bar, I'll be able to see what pressure the oil pump actually makes. I'll get back to you with another redesign of the electrical circuitry. Jeremy

__________________

"Buster" in the '95 Our all-Diesel family 1996 E300D (W210) . .338,000 miles Wife's car 2005 E320 CDI . . 113,000 miles My car Santa Rosa population 176,762 (2022) Total. . . . . . . . . . . . 627,762 "Oh lord won't you buy me a Mercedes Benz." -- Janis Joplin, October 1, 1970 |

|

#172

|

||||

|

||||

|

Tapped hole for low oil pressure switch

The VW oil pressure alarm switch has a 10x1.0 mm thread. It's a straight or machine screw thread that uses a seal ring as you can see in the picture. This thread is very close to a 1/8 inch pipe thread; you will find taps in your local hardware store marked "1/8 B.S.P." (British Standard Pipe) The two threads are very similar and easy to confuse.

The long tap in the picture is the metric 10X1.0 mm tap while the short one is 1/8" pipe. When you're getting ready to install the oil pressure switch in the lid of your oil filter assembly you will want to make sure you have the right tap. Although you can thread the switch into a hole tapped with the 1/8 pipe tap, only a few threads will go in and the joint will be weak and might leak. Using too much torque may strip the threads. Use the 1/8" pipe tap only if you cannot get the correct metric tap. Using the correct 10X1.0 mm tap will allow the oil pressure switch to screw in all the way. The seal ring is aluminum (copper is also used) and crushes a little as it seals the joint. Interestingly, the metric tap (a NAPA product) is marked as a "spark plug" tap. I don't know what kind of small engine would use such a little spark plug, maybe a chain saw or weed whacker? I'm still working on the electrical part of the alarm. Jeremy

__________________

"Buster" in the '95 Our all-Diesel family 1996 E300D (W210) . .338,000 miles Wife's car 2005 E320 CDI . . 113,000 miles My car Santa Rosa population 176,762 (2022) Total. . . . . . . . . . . . 627,762 "Oh lord won't you buy me a Mercedes Benz." -- Janis Joplin, October 1, 1970 |

|

#173

|

||||

|

||||

|

Sixto's concern

By email, Sixto has expressed his concern that the oil filter housing does not see full oil pressure. He commented "I don't think the cover o-ring can hold back 80 psi of oil." RS899 asked that question in an earlier post.

Looking at the diagram of the oil circuit, however, it looks like all of the oil is sent from the oil pump from the sump to the oil filter housing, there to flow through the filter (sometimes going through the oil cooler first) and out to the engine, plus a little bit going through the bypass section of the filter and back to the sump. I'd appreciate reading others' opinions. I have a spare cover (thanks to Mr. Hendy) that I can experiment with. If it turns out that the filter housing does not see full pressure, I can always tee the connection at the electric gauge sender. Jeremy

__________________

"Buster" in the '95 Our all-Diesel family 1996 E300D (W210) . .338,000 miles Wife's car 2005 E320 CDI . . 113,000 miles My car Santa Rosa population 176,762 (2022) Total. . . . . . . . . . . . 627,762 "Oh lord won't you buy me a Mercedes Benz." -- Janis Joplin, October 1, 1970 |

|

#174

|

||||

|

||||

|

Oil filter housing cover = NO GO

I drilled and tapped a hole in my spare oil filter housing cover (identical to the one that's on the car, same part number) and mounted a mechanical oil pressure gauge in it. The purpose was to answer the question "does the filter housing see the same pressure as the electric pressure sender?" Turns out the answer is "yes" while the oil is cold but as the temperature rises the pressure in the housing falls.

Once the oil is warm enough for the instrument cluster's oil pressure gauge to fall off of the stop (3 bars) at idle, the gauge in the filter cover is down to zero pressure. Apparently the hot oil flows through the filter so easily that little pressure builds up. Above idle there is pressure in the filter housing (as much as 50 psi) but if you use that location for an alarm switch you'll have an alarm anytime you let off the throttle. NOTE: In this experiment, the car had been driven earlier in the day but was parked for a couple of hours while I did the machine work. Although the engine was "warm," it was not at full operating temperature; if it had been, the oil pressure would have been just below 2 bars at idle. It still might work if you used a pressure switch in the intake manifold to sense boost but I'm trying to come up with a solution that is usable by turbo and non-turbo models both. Looks like I'll have to tee the outlet for the electric sender and add the pressure switch there. The pictures show (1) Tapping operation (2) VW 1.4 bar pressure switch in tapped hole, as suggested earlier in this thread (3) Instrument cluster, engine warm and at idle, oil pressure < 3 bars (4) Gauge in cover showing close to zero pressure at idle (taken seconds after picture 3) Edit: The 5th picture shows the high pressure (almost 60 psi) that exists in the filter canister when the engine is first started from cold (ambient outside temperature about 60F) and is idling at 600-700 RPM. Jeremy :EDIT: Error - Error - Error -------------------------------------------------------------------------------- My post #174 in this thread is in error (but why can't I edit it?). Turns out the oil filter cannister DOES see full system oil pressure -- I thought it didn't because my cheap mechanical oil pressure gauge (now in the garbage can) was defective! My new VDO 100 psi mechanical gauge works great in the filter cover of my 1987 300D Turbo (W124, OM603). At cold startup, system pressure is 60 to 70 psi (4+ bars) while at hot idle it is about 20 psi (1+ bar). Give the engine some throttle and the pressure immediately jumps up to at least 50-60 psi. As several others have noted, the factory gauge is more of a "serving suggestion" than a "real" oil pressure gauge. Assuming the new VDO gauge is accurate (and how would I know?), I plan to adjust the needle of my cluster's pressure gauge so that it reads more like the VDO. That and the low-pressure alarm (I'm almost finished!) will give me a bit more peace of mind. Jeremy

__________________

"Buster" in the '95 Our all-Diesel family 1996 E300D (W210) . .338,000 miles Wife's car 2005 E320 CDI . . 113,000 miles My car Santa Rosa population 176,762 (2022) Total. . . . . . . . . . . . 627,762 "Oh lord won't you buy me a Mercedes Benz." -- Janis Joplin, October 1, 1970 Last edited by whunter; 06-24-2010 at 01:41 PM. Reason: OP request |

|

#175

|

|||

|

|||

|

What's wrong with somehow using the existing electrical oil pressure sensor?

|

|

#176

|

||||

|

||||

|

That would show different resistance through the whole pressure range. For a low pressure switch you would need to determine what low pressure you want and the switch would have to either open or close at that set pressure ( depending on your setup ) triggering a light or alarm.

__________________

Experience : what you receive 3 seconds after you really needed it !! 86 300SDL 387,000? Motor committed suicide 81 300SD 214,000 "new" 132,000 motor 83 300SD 212,000 parts car 83 300SD 147,000 91 F700 5.9 cummins 5spd eaton 298,000 66 AMC rambler American 2dr auto 108,000 95 Chevy 3/4 ton auto 160,000 03 Toyota 4runner 180,000 wifes |

|

#177

|

||||

|

||||

|

Quote:

Here is my old thead: Low oil pressure alarm for 617.952 Also using the Monovalve as a power source has caused no problems.

__________________

84 300D, 82 Volvo 244Gl Diesel Last edited by Diesel911; 03-28-2010 at 06:18 PM. |

|

#178

|

|||

|

|||

|

Why does the dash message board say Im low on oil when IM not

Could anyone help me with this issue? The Dash message board says the engine is low on oil when it is in fact is on the high side of the middle. Should I be worried or should I be doing something to protect myself? Thanks

|

|

#179

|

||||

|

||||

|

Quote:

I am not sure what the fix is for that as my car does not have this device. If you measured your Oil level with the Dip Stick and it is OK you have nothing to worry about. There is no replacement that is better than you actually checking the Oil level yourself. Also a low Oil Presssure Alarm is different from a Low Oil Level Alarm/warning light. As an example if the chain driving your Oil Pump broke your Oil pressure would go to zero but you would still have a full crankcase of Oil.

__________________

84 300D, 82 Volvo 244Gl Diesel |

|

#180

|

||||

|

||||

|

Plumbing

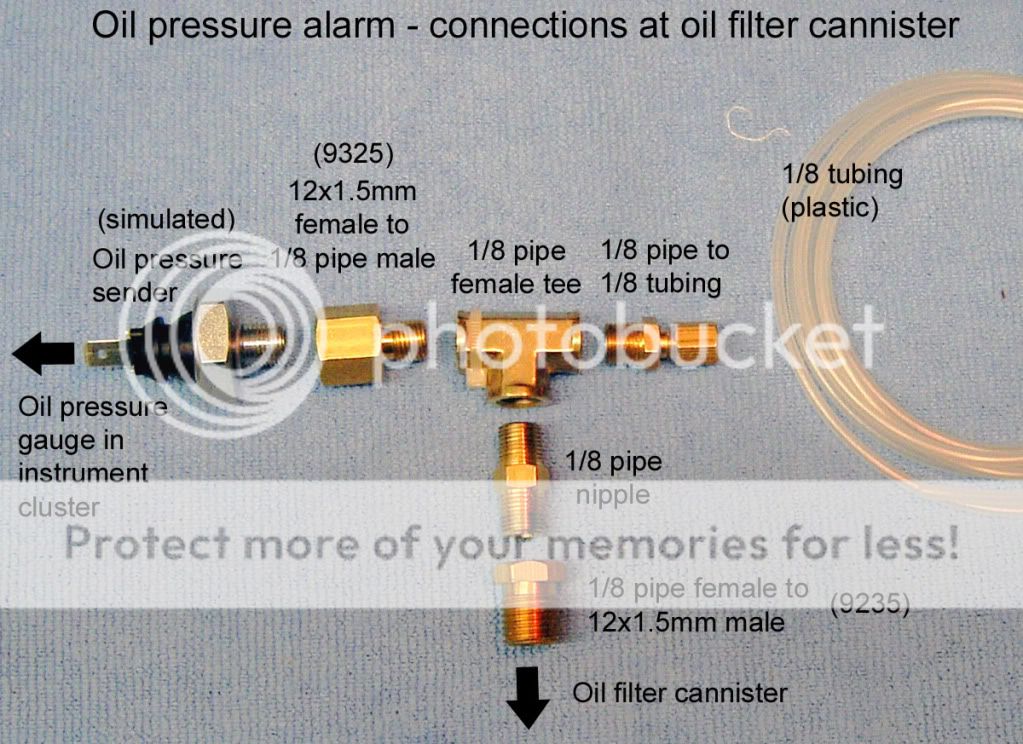

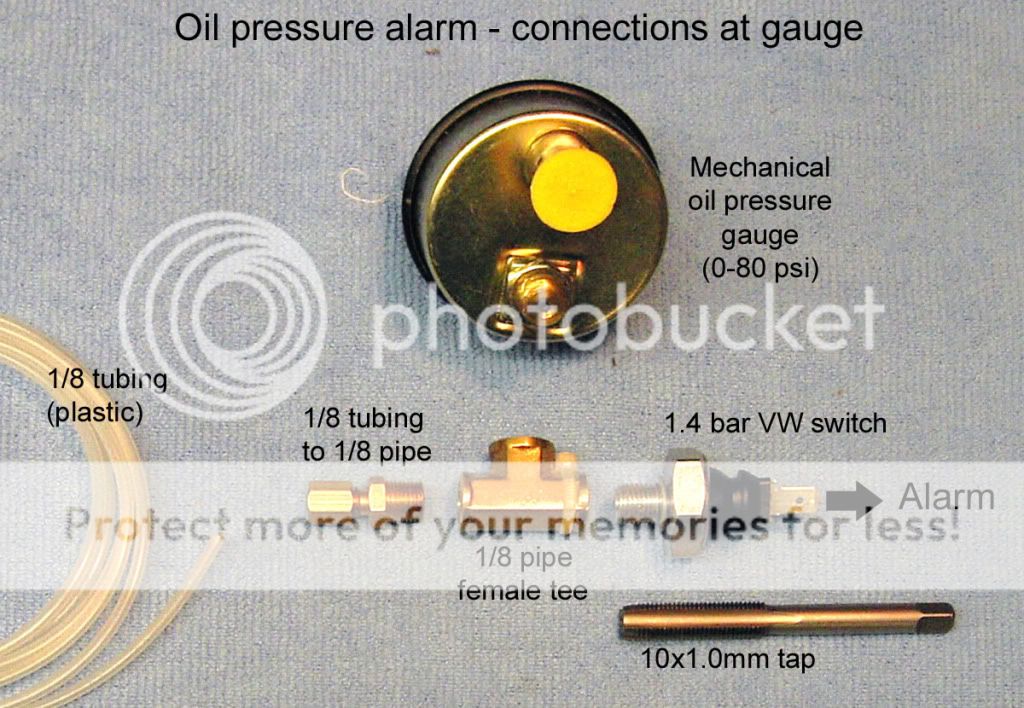

Here is the plumbing side of my low oil pressure alarm. Caveat: some of the fittings in the photos are simulated with parts from my junk box -- I don't have all the right parts yet.

The first picture shows the components needed to tee into the port on the oil filter cannister where the electric oil pressure sender connects. This will work on any Mercedes engine that uses a sender with a 12x1.5mm thread. One side of the tee accepts the electric sender and the other side adapts to 1/8" tubing. The two fittings that may take a bit of finding are the two metric adapters. The hydraulic and plumbing catalogs use the numbers "9325" and "9235" for these two parts as shown in the first picture. Some auto parts stores may stock these adapters or be able to order them and there are many on-line sources.  The second picture shows the connections at the other end of the plastic tubing. The tubing goes into another tee to which is connected the VW 1.4 bar switch and a mechanical oil pressure gauge. One leg of the tee needs to be re-tapped with a 10x1.0mm Metric tap for the VW switch. Although the (metric) VW switch will screw into the (NPTF) tee part way, the threads are incompatible and the junction may leak. Retapping the 1/8 NPTF threads to 10x1.0mm metric is a trivial task -- the threads and diameter are very similar. The gauge and VW switch can be mounted under the hood (my choice) or in the cabin where the driver can see the gauge. Be sure to run the plastic tubing inside a larger piece of tubing for protection against abrasion, cuts, and pinching.  For those who don't want to bother with a gauge, the tee in the first picture can be modified so the electric sender screws into one leg and the VW switch screws into the other. I'll post the electrical half of the alarm when I finish installing the plumbing in my '87. Jeremy

__________________

"Buster" in the '95 Our all-Diesel family 1996 E300D (W210) . .338,000 miles Wife's car 2005 E320 CDI . . 113,000 miles My car Santa Rosa population 176,762 (2022) Total. . . . . . . . . . . . 627,762 "Oh lord won't you buy me a Mercedes Benz." -- Janis Joplin, October 1, 1970 |

|

| Bookmarks |

|

|