|

|

|

|

|

|

|

|

|

|

|

#16

|

|||

|

|||

|

I had a cracked head, and "while I was at it," I decided to change the delivery valve seals. And the timing chain tensioner rail, oil pump chain tensioner rail, motor mounts, heater core, etc, etc... Anyway, I must've inadvertently moved the barrel. I fear that I've also now distorted the locating pin, so I'd like to remove the barrel completely to check everything out. I feel very silly... I'm a mechanical engineer, in the engine business, a former mechanic for many years, just never got into an IP before. I'd read up on the o-ring replacement job, and hadn't come across any reference to the possibility of getting the barrel out of position.

The OD of the barrel is close to the ID of the threaded bore. I can't see any possibility of getting forceps of any kind in there. I was thinking about a strong magnet. |

|

#17

|

||||

|

||||

|

Quote:

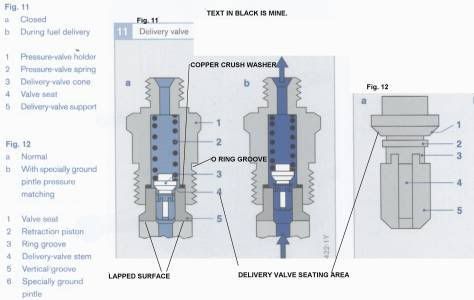

The good news is that although they had been torqued in the wrong position previously they did not report any damage that has kept the IP from functioning ounce the Barrel was back were it was supposed to be. I have guessed that somehow the parts were stuck together enough to cause the Barrel to be able to be lifted enough to go above the alignment pin while it is being taken apart. It migh be possible that you could use sticking idea to your advantage and put a thin layer of grease on the lower cylinderical part of the Delivery Valve- part #5 in the pic; press it together and lift it gently. Afterwhich you will need to wipe and flush out the grease. Of course a magnet will work but make sure it is clean. Also I you look at the previous post that has the Element/Plunger and Barrely in it you will notice that the Plunger Part can also be gotton 180 degrees out of alignment if it is pulled out. If it comes out with the Barrel pay attention to the way it was positioned so it can go back the same way.

__________________

84 300D, 82 Volvo 244Gl Diesel Last edited by Diesel911; 02-06-2009 at 02:46 AM. |

|

#18

|

|||

|

|||

|

I used a magnet to get the barrell out. I just kept, tapping, pulling and wiggling and it eventually came out. Then I used the magnet to rotate the barrell, very slowly, until I could tell it was aligned correctly. When it aligns, it will drop farther into the IP housing. Diesel 911 is correct in that all the parts were stuck together. When I pulled out the delivery valve to change the o-ring, all the parts started coming with it. The barrell was raised just enough to spin and become out of alignment. - Tim

|

|

#19

|

|||

|

|||

|

Thanks guys, I'm planning on getting into it Saturday, will let you know how it works out.

|

|

#20

|

|||

|

|||

|

Injection Pump Special Tool Question

Try as I might, I couldn't get the barrel to come up to get it back into position while the pump was on the engine. I had no choice but to remove the IP. The manual shows a special tool -- sometimes called a "centering tool," but it gives little information about it's function or how to use it. It looks just like the "assembly cage" that has to be removed to install the tool. The assembly cage fits very close to but does not touch a pilot diameter on the IP sprocket. I imagine that the centering tool is supposed to hold the IP sprocket in position while the IP is removed. What I did was take the assembly cage and wrap a bunch of turns of electrical tape around the part that fits close to the IP sprocket. Then I put it back in and tightened it down against the sprocket *hoping* it will keep it in position just as well as the special tool would -- if that in fact is what the tool does.

So I need to know... am I ok? Or does the tool have a more sophisticated function? As to the pump problem... when I had the pump out I was able to remove the barrel and position it properly. Fortunately it was the number 1 barrel. The fuel inlet hole provides a bit of access to the barrel OD, and there is a threaded plug on the front of the pump that also gives access to the barrel. I was able to get a couple of screwdrivers in there and work the barrel out. Taking off the side cover gives access to the locating pins... they are close fits in small bores inside the cover. The pins are installed and then their bosses are lightly peened to stake them in place. It was obvious that my number one pin had been pushed back a bit when the barrel was mispositioned. I pushed the pin back into place, then reinstalled the barrel, delivery valve, and holder. Tomorrow I'll install the pump (as long as my makeshift tool is adequate). The barrel was really stuck in there... When the pump was still on the engine I had a magnet with a nine pound pull on the barrel while I was working at it with a screwdriver through the fuel inlet. It wiggled a bit, but wouldn't come up until I had the pump on the bench. I don't know what I would've done if it were not number 1. Anyway... anybody know about that centering tool??? Thanks! |

|

#21

|

||||

|

||||

|

Quote:

Incase this happens to someone else do you think that the plug in front of the IP can be removed and the Barrel accessed while it is on the Engine? Sorry I cannot help with the "cage" thing I have no experience with your type of Engine and no manual for it either.

__________________

84 300D, 82 Volvo 244Gl Diesel |

|

#22

|

|||

|

|||

|

If someone else has a problem with the #1 delivery valve, you might also be able to reach the barrel by taking off the fuel shut off selenoid.. - Tim

|

|

#23

|

|||

|

|||

|

Finished, the car works. Unfortunately by driving it for a couple of hundred miles on 4 out of 5 cylinders, I spun the crank damper a little. The pin for the injection timing tool no longer lines up properly when the crank is at 15 deg. ATDC. It looks to be off by about 5 degrees. I believe, but am not certain, that the numbers are still correct. Anyway, I timed the pump to the numbers and the car drives nicely, but it has more diesel clatter than before at idle (and only at idle). I think the timing may be off a few degrees.

To time the pump I made a tool to hold that little protrusion in the pump. I took a brass hose barb that was a close fit in the pump bore. I cut a little slot in the end with a hacksaw, and then used a pattern file to make it fit the protuberance. I cut the barb just short enough that the plug would hold it in place and lock the pump cam from turning. Worked fine. The "assembly cage" tool... My electrical tape thing worked fine, also. I suspect that this assembly cage serves only the purpose of holding the pump sprocket in position during assembly at the factory. It was eliminated on later cars. On later cars one would need the special tool instead of electrical tape. |

|

#24

|

|||

|

|||

|

Quote:

Removing the pump isn't *that* bad a job. I haven't any idea how one would deal with this problem on any barrel other than number one, even with the pump out, short of disassembling a lot of the pump. |

|

#25

|

||||

|

||||

|

Quote:

Oddly where rotating the barrel back in place fixed the problem for the last 3 Members it has been on #1.

__________________

84 300D, 82 Volvo 244Gl Diesel |

|

#26

|

|||

|

|||

|

Yes, I noticed that also. Perhaps when we've all changed our delivery valve seals we've started with number one and were more hamfisted on the first try. Could also be some anomaly in the pump where the number one barrel has a slightly looser fit.

|

|

| Bookmarks |

| Thread Tools | |

| Display Modes | |

|

|