|

|

|

|

|

|

|

|

|

|

|

#1

|

||||

|

||||

|

Injector Removal DIY

Since I bought the tools and had not done it before, I figured I'd take pictures and do a little DIY for the injector removal process. It is pretty easy, but all the same, pictorials do help.

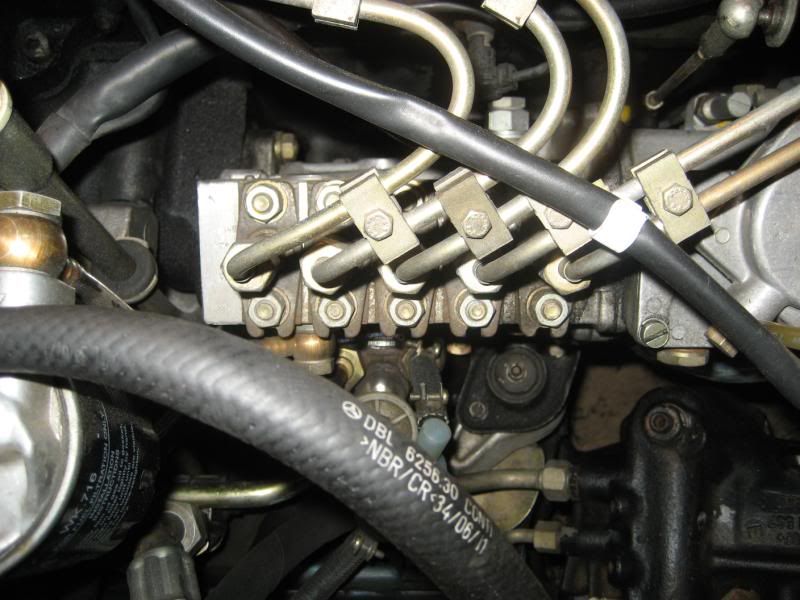

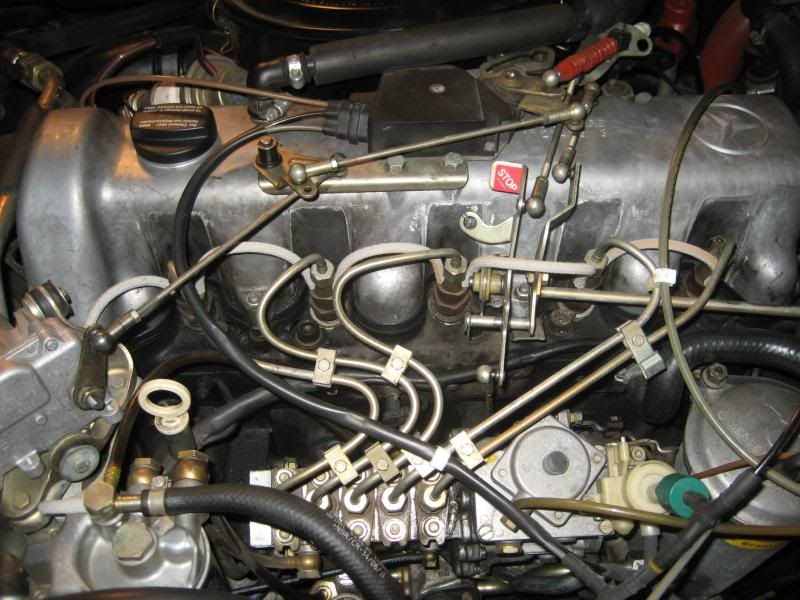

I used: -Hazet injector socket (likely not needed) -Hazet injector line removal tool -1/2" drive ratchet -short and long extension -impact wrench I used the impact gun at the advisement of the posters in my earlier thread on how long it would take to remove them. They do require a fair amount of torque, and I found that there was just too much slop using the socket, an extension and the ratchet, by popping the ratchet. A T-bar would be better, but since I have an impact gun for changing wheels, it really helped, and made it faster too! Obviously these are the two items you want to work on:   You can use the hazet tool to remove injector lines. IMO this is the more important tool than the special socket, which plenty of folks have claimed works fine with a regular one of the appropriate size.    Despite having the special socket, I used a razor and cut the return hoses just above the barbs. This way there was no chance of any damage, since there is rubber protecting them:  Now, this is where the special tool comes in handy - it is easy to remove the lines with them all connected and attached together.  So I could remove the "spider" all together. No need to label lines:  I tried to use my ratchet, but there was too much slop. Since it was recommended to "pop" the injectors out vice putting constant torque on, I went and got my impact gun. It actually took a fair amount of impacting (and I have a pretty heavy-duty gun) to get the injectors loose. However, at least I wasnt torquing them from all different angles.  From there, they can come right out!  Mine were all wet. Be careful with the diesel that will run out, and keeping grit out of the prechamber holes. I found that most were wet with fuel, and some had grit in there too.  I would say that if you have a bad hood liner, replace it and vacuum/blow off the engine before doing this. That junk can get all over! Hope this helps. It was an easy job with the right tools!

__________________

Current Diesels: 1981 240D (73K) 1982 300CD (169k) 1985 190D (169k) 1991 350SD (113k) 1991 350SD (206k) 1991 300D (228k) 1993 300SD (291k) 1993 300D 2.5T (338k) 1996 Dodge Ram CTD (442k) 1996 Dodge Ram CTD (265k) Past Diesels: 1983 300D (228K) 1985 300D (233K) |

|

#2

|

||||

|

||||

|

wow, great job! great pics!

I REALLY want one of those line wrenches!!!

__________________

John HAUL AWAY, OR CRUSHED CARS!!! HELP ME keep the cars out of the crusher! A/C Thread "as I ride with my a/c on... I have fond memories of sweaty oily saturdays and spewing R12 into the air. THANKS for all you do! My drivers: 1987 190D 2.5Turbo 1987 190D 2.5Turbo 1987 190D 2.5-5SPEED!!!  1987 300TD 1987 300TD 1994GMC 2500 6.5Turbo truck... I had to put the ladder somewhere! |

|

#3

|

||||

|

||||

|

The Line Wrench (I have one that came in a lot of tools I bought on Ebay) is nice but I have seen them break before. And, your Heart rellay sinks when that happens.

If you have never had the Hard Lines loose on your Car the first time you loosen them use a 17mm Flare Nut Wrench or a Flare Nut Crows foot. After that you can use the Hazet Line Wrench all you want. If you insist on using only the Line Wrench keep an eye on the jaws of the Wrench and if jaws start to spread stop and use another wrench. Other than the above the Hazet Line Wrench is one of the tools I always keep in my Tool box of frequently used tools and it does make the job a little easier. I have been using the same a Craftsman 12 point 1-1/16" Deep Socket since 1975 on Injectors and other things and it has never failed. For those who want the Hazet Performance the Craftsman did not cost much and still works. Since it is deep all the way to the bottom like the Hazet one it has never bent any return nipples.

__________________

84 300D, 82 Volvo 244Gl Diesel |

|

#4

|

|||

|

|||

|

Quote:

__________________

Charles 1983 300D, bought new, 215k+ miles, donated to Purple Hearts veterans charity but I have parts for sale: http://www.peachparts.com/shopforum/mercedes-benz-cars-sale/296386-fs-1-owner-83-mb-300d-turbo-rebuild-parts.html |

|

#5

|

||||

|

||||

|

Yeah, keeping the hoses over he barbs on the return lines, I really do not see a reason for a special socket.

__________________

Current Diesels: 1981 240D (73K) 1982 300CD (169k) 1985 190D (169k) 1991 350SD (113k) 1991 350SD (206k) 1991 300D (228k) 1993 300SD (291k) 1993 300D 2.5T (338k) 1996 Dodge Ram CTD (442k) 1996 Dodge Ram CTD (265k) Past Diesels: 1983 300D (228K) 1985 300D (233K) |

|

#6

|

||||

|

||||

|

Quote:

The hazet tool is on my shopping list

__________________

1982 240D, sold 9/17/2008 1987 300D TurboW124.133 - 603.960, 722.317 - Smoke Silver Metallic / Medium Red (702/177), acquired 8/15/2009 262,715 and counting  |

|

#7

|

||||

|

||||

|

I have a HF deep impact socket set that goes up to 30 mm. The 27 mm socket in the set is 27 mm deep all the way and works perfect for the injectors.

__________________

85 300D turbo pristine w 157k when purchased 161K now 83 300 D turbo 297K runs great. SOLD! 83 240D 4 spd manual- parted out then junked |

|

#8

|

||||

|

||||

|

Quote:

Well I undrstand buying the Hazet socket to a point. He simply wanted a high quality tool. Since this Thread got me thinking about Injector Sockets I bought one at the local tool outlet for less than $5. A Calhawk Deep Impact Socket. Since I only bought it a few hours ago I have not tried it out yet but It looks like it ought to work OK. See pics. The top of the Injector does go though and rest on the 1/2 inch drive. So I suppose there is a slight chance that it could bugger the lip around the threaded area where the Hard Lines go. In the pic you can see the Craftsman Socket is longer but that both sockets easly grip the Injector Hex with room to spare. I think I will cut out a circular piece of rubber and insert it into the Impact socket to prevent any Metal to Metal contact at the top. In the last pic you can see it is deep all the way to the end and that will prevent the Return Line Nipples from getting buggered up.

__________________

84 300D, 82 Volvo 244Gl Diesel |

|

#9

|

||||

|

||||

|

Quote:

I do not know if the number is still current since I bought my socket a long time ago, but the part number on my Craftsman Socket is #47532 (for a 1-1/16" one 1/2" drive). The overall length is 3-1/4 inches.

__________________

84 300D, 82 Volvo 244Gl Diesel Last edited by Diesel911; 06-08-2010 at 06:48 PM. |

|

#10

|

||||

|

||||

|

Quote:

I sure wish it was... I'll definitely have a deep enough tool for when I replace my injectors

__________________

1982 240D, sold 9/17/2008 1987 300D TurboW124.133 - 603.960, 722.317 - Smoke Silver Metallic / Medium Red (702/177), acquired 8/15/2009 262,715 and counting  |

|

#11

|

||||

|

||||

|

Quote:

I added this to my post; the over all length is 3-1/4 inches Right now I am also on the Sears sight just to see what they actually have now.

__________________

84 300D, 82 Volvo 244Gl Diesel |

|

#12

|

||||

|

||||

|

Quote:

I did find it because I was searching for sockets, but in hindsight I still don't necessarily really see the need if a standard available item works. The barbs just aren't an issue if you leave the hoses on a bit, IMHO.

__________________

Current Diesels: 1981 240D (73K) 1982 300CD (169k) 1985 190D (169k) 1991 350SD (113k) 1991 350SD (206k) 1991 300D (228k) 1993 300SD (291k) 1993 300D 2.5T (338k) 1996 Dodge Ram CTD (442k) 1996 Dodge Ram CTD (265k) Past Diesels: 1983 300D (228K) 1985 300D (233K) |

|

#13

|

|||

|

|||

|

Just did this job and found that crow foot does just fine. Btw, I loosen the injector line brackets slightly so that lines have movement while still remaining "ganged" together -refitting is very easy this way. Good time to take a compression test when performing this job and I released pressure on system first by loosening banjo fittings at filter. New heat shields are imperative, in fact I keep them new on hand for future injector work. For those of you driving around on ancient injectors of unknown mileage, bite the bullet and buy new nozzles, and have them calibrated for correct pop pressure and spray pattern -you will be amazed! This is a very satisfying job where you can truly feel the results! Good luck!

|

|

#14

|

||||

|

||||

|

Quote:

From the pic the Hazet Socket easily has twice + the wall thickness of the Craftsman one; so it is clearly stronger.

__________________

84 300D, 82 Volvo 244Gl Diesel |

|

#15

|

||||

|

||||

|

recycled

for new members

__________________

ASE Master Mechanic asemastermechanic@juno.com Prototype R&D/testing: Thermal & Aerodynamic System Engineering (TASE) Senior vehicle instrumentation technician. Noise Vibration and Harshness (NVH). Dynamometer. Heat exchanger durability. HV-A/C Climate Control. Vehicle build. Fleet Durability Technical Quality Auditor. Automotive Technical Writer 1985 300SD 1983 300D 1984 190D 2003 Volvo V70 2002 Honda Civic https://www.boldegoist.com/ |

|

| Bookmarks |

|

|