|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

LinkBack | Thread Tools | Display Modes |

|

#16

|

|||

|

|||

|

Quote:

He knows that, we know that.. he is just dealing with cabin fever... if you see the other thread you will understand that..

__________________

1980 240d , chain elongation, cam marks reference: http://www.peachparts.com/shopforum/diesel-discussion/10414-help-i-need-check-stretch.html http://www.peachparts.com/shopforum/diesel-discussion/305365-9-degrees-chain-stretch.html evap fin cleaning: http://www.peachparts.com/shopforum/diesel-discussion/156207-photo-step-step-post-showing-w123-evaporator-removal-1983-240d-1982-300td.html?highlight=evaporator A/C thread http://www.peachparts.com/shopforum/diesel-discussion/297462-c-recommendations-mb-vehicles.html |

|

#17

|

|||

|

|||

|

Quote:

Assuming I guess that you could do it fast enough that none was lost past the rings at the bottom ...

__________________

1980 240d , chain elongation, cam marks reference: http://www.peachparts.com/shopforum/showthread.php?threadid=10414 http://www.peachparts.com/shopforum/diesel-discussion/305365-9-degrees-chain-stretch.html evap fin cleaning: http://www.peachparts.com/shopforum/diesel-discussion/156207-photo-step-step-post-showing-w123-evaporator-removal-1983-240d-1982-300td.html?highlight=evaporator A/C thread http://www.peachparts.com/shopforum/diesel-discussion/297462-c-recommendations-mb-vehicles.html |

|

#18

|

|||

|

|||

|

Quote:

Others should remember that increasing the compression ratio does not increase power... UNLESS More fuel is added... and may decrease available power if the heat from compression was already sufficient to completely burn the fuel in the proper time span... you would be talking MORE load ( ... and without added fuel.. less power NET ).....

__________________

1980 240d , chain elongation, cam marks reference: http://www.peachparts.com/shopforum/showthread.php?threadid=10414 http://www.peachparts.com/shopforum/diesel-discussion/305365-9-degrees-chain-stretch.html evap fin cleaning: http://www.peachparts.com/shopforum/diesel-discussion/156207-photo-step-step-post-showing-w123-evaporator-removal-1983-240d-1982-300td.html?highlight=evaporator A/C thread http://www.peachparts.com/shopforum/diesel-discussion/297462-c-recommendations-mb-vehicles.html |

|

#19

|

||||

|

||||

|

Quote:

Back to the old thread:- Timing adjustment methods

__________________

1992 W201 190E 1.8 171,000 km - Daily driver 1981 W123 300D ~ 100,000 miles / 160,000 km - project car stripped to the bone 1965 Land Rover Series 2a Station Wagon CIS recovery therapy! 1961 Volvo PV544 Bare metal rat rod-ish thing I'm here to chat about cars and to help others - I'm not here "to always be right" like an internet warrior Don't leave that there - I'll take it to bits! |

|

#20

|

||||

|

||||

|

Quote:

__________________

1992 W201 190E 1.8 171,000 km - Daily driver 1981 W123 300D ~ 100,000 miles / 160,000 km - project car stripped to the bone 1965 Land Rover Series 2a Station Wagon CIS recovery therapy! 1961 Volvo PV544 Bare metal rat rod-ish thing I'm here to chat about cars and to help others - I'm not here "to always be right" like an internet warrior Don't leave that there - I'll take it to bits! |

|

#21

|

||||

|

||||

|

Right back to the drawing board - how about this for a method?

I think I have probably re-invented the wheel - meaning I guess this has been done before. Can anyone identify it?

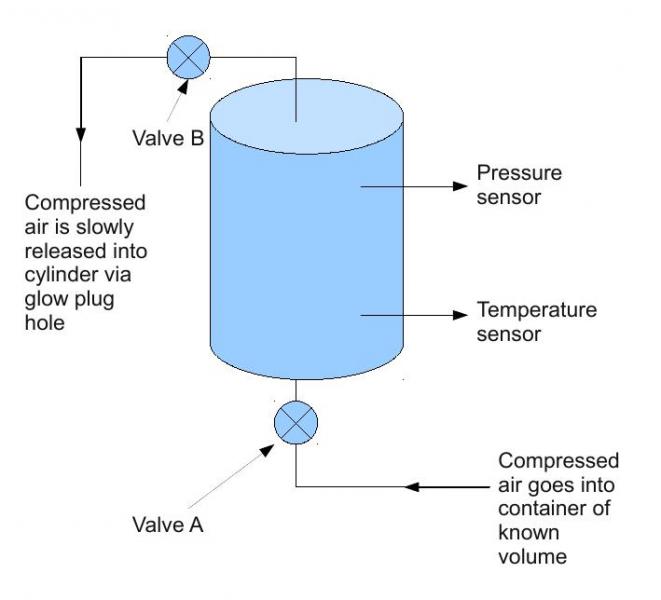

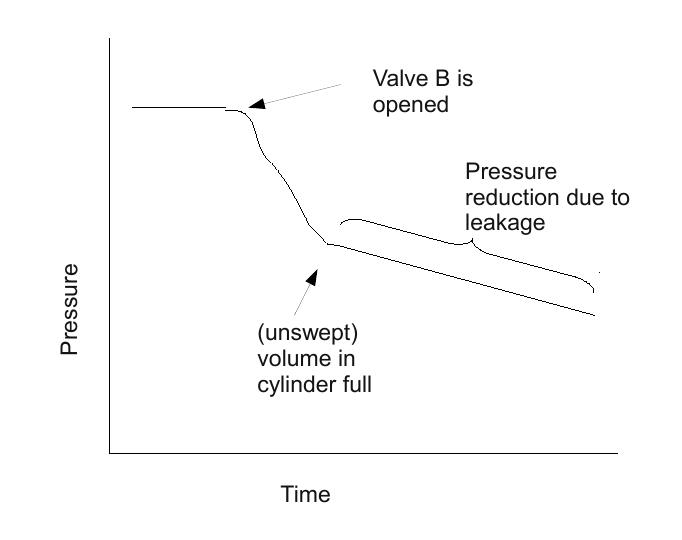

Objective:- to measure the unswept volume of a piston engine without taking it apart. It occurred to me that if you could use a large volume - much larger than the swept volume of a cylinder - to hold a compressed gas (I'll start with air) you could use an equation of state to estimate an equivalent volume in the following way.  You close off valve B and fill a volume of known size with compressed air. You can't use too high a pressure as when you transfer this to the cylinder in the engine, too high a pressure could turn the crank. So fill it say with compressed air to about 15 / 20 PSI. Close valve A and allow the temperature in the known volume to settle. This is important it must remain constant - the pressure also needs to stay constant too! Remove a glow plug in the engine and turn the crank until the piston for that cylinder is at TDC. This can be checked by dropping a valve on top of a piston crown and measuring the deflection with a DTI (Described a little bit more here:- Timing marks gone from my OM617 engine). Connect the pipe running from valve B to the glow plug hole. Very slowly open valve B so that the compressed air in the known volume goes into the cylinder. Keep an eye on the temperature in the known volume to make sure that doesn't change. If you do it too fast the volume will cool (expanding gas). Measure and record the temperature of the pressure on some sort of recording system (yeah I know this is a big problem for the average DIY home mechanic!). I would expect to get something that would look like this:-  If the flow of air going into the unswept volume of the cylinder is higher than the flow out of the clylinder due to leakage (then your engine is still quite healthy!) you could then "simply" calculate the true pressure drop within the known volume that is caused by the displacement of gas to the unswept volume of the cylinder. You'd need to assume that the cylinder leaked at a constant rate as recorded in the last part of the plot (see above) and subtract this pressure from the initial pressure drop. Taking this measured pressure drop you could do some high school mathematics with an equation of state (http://en.wikipedia.org/wiki/Equation_of_state#Peng-Robinson_equation_of_state for example) and calculate an equivalent change in volume for the change in pressure. I think that should be equal to the unswept in the cylinder. As leathermang said I do have a serious case of cabin fever!

__________________

1992 W201 190E 1.8 171,000 km - Daily driver 1981 W123 300D ~ 100,000 miles / 160,000 km - project car stripped to the bone 1965 Land Rover Series 2a Station Wagon CIS recovery therapy! 1961 Volvo PV544 Bare metal rat rod-ish thing I'm here to chat about cars and to help others - I'm not here "to always be right" like an internet warrior Don't leave that there - I'll take it to bits! Last edited by Stretch; 01-31-2011 at 01:31 PM. Reason: I made some corrections... |

|

#22

|

|||

|

|||

|

On the other hand.... this is as good a use of winter down time I have ever seen...

When warm weather hits... you should be armed with dozens of techniques and possibly tools for measuring all sorts of physical phenomenon...... whether they need to be measured or not....LOL

__________________

1980 240d , chain elongation, cam marks reference: http://www.peachparts.com/shopforum/showthread.php?threadid=10414 http://www.peachparts.com/shopforum/diesel-discussion/305365-9-degrees-chain-stretch.html evap fin cleaning: http://www.peachparts.com/shopforum/diesel-discussion/156207-photo-step-step-post-showing-w123-evaporator-removal-1983-240d-1982-300td.html?highlight=evaporator A/C thread http://www.peachparts.com/shopforum/diesel-discussion/297462-c-recommendations-mb-vehicles.html |

|

#23

|

|||

|

|||

|

Army, How do YOU define unswept volume ?... and why are you interested in it ?

I am having trouble visualizing unswept except with regards to that volume INSIDE the precombustion chamber.. which would not be swept but only pressure compressed as the piston drives upwards.... but once the fuel has been ejected... I suspect due to the very small size of the only connections to the bore ( the fuel spray holes ) it is not in any meaningful way ' swept'.. But what difference does the amount of swept area make ? If it does exist at all.. it is certainly tiny in a diesel engine compared to gas engines due to the high compression ratio....

__________________

1980 240d , chain elongation, cam marks reference: http://www.peachparts.com/shopforum/showthread.php?threadid=10414 http://www.peachparts.com/shopforum/diesel-discussion/305365-9-degrees-chain-stretch.html evap fin cleaning: http://www.peachparts.com/shopforum/diesel-discussion/156207-photo-step-step-post-showing-w123-evaporator-removal-1983-240d-1982-300td.html?highlight=evaporator A/C thread http://www.peachparts.com/shopforum/diesel-discussion/297462-c-recommendations-mb-vehicles.html |

|

#24

|

||||

|

||||

|

Yeah bloody pre-chambers...

Quote:

I've measured the clearance between the top of the piston and the head on my OM617 to be about 2mm (see OM617 (non turbo) cam profile specs, piston height specs etc). It seems to me that the head gasket, which is 2.2mm in an uncompressed state, does not get compressed very much when you fit the head. I'm surprised - but I also get the feeling that if I had made better measurements of how far the valves are recessed into the head then perhaps I'd be able to have a better idea of this. Anyway like you say the size of the unswept volume in a diesel engine is tiny. But you've also brought up another interesting problem that has been bothering me - the influence of the pre-chambers. I'm guessing that the pre-chambers contribute greatly to the OM617's clackety sound. I think they act as resonant chambers. But they also have some effect on the compression in the cylinder (they must do) but I don't think it would be to the extent that one may assume. I don't expect at normal engine speeds there is much "flow" (dodgy term I know) from the cylinder into the pre-chamber. I think that the friction of the gas in those little holes acts more like a sealed surface than an "open" way into the pre-chamber. I have a gut feeling that you get more "flow" (dodgy term again!) of the fuel mixture going into the cylinder than you get gas returning from the cylinder. It would be interesting to find out if Mercedes considered the pre-chamber volume to be part of the unswept volume or not.

__________________

1992 W201 190E 1.8 171,000 km - Daily driver 1981 W123 300D ~ 100,000 miles / 160,000 km - project car stripped to the bone 1965 Land Rover Series 2a Station Wagon CIS recovery therapy! 1961 Volvo PV544 Bare metal rat rod-ish thing I'm here to chat about cars and to help others - I'm not here "to always be right" like an internet warrior Don't leave that there - I'll take it to bits! |

|

#25

|

||||

|

||||

|

Quote:

At this stage I don't know what is worth measuring or not - but I intend to find out!

__________________

1992 W201 190E 1.8 171,000 km - Daily driver 1981 W123 300D ~ 100,000 miles / 160,000 km - project car stripped to the bone 1965 Land Rover Series 2a Station Wagon CIS recovery therapy! 1961 Volvo PV544 Bare metal rat rod-ish thing I'm here to chat about cars and to help others - I'm not here "to always be right" like an internet warrior Don't leave that there - I'll take it to bits! |

|

#26

|

|||

|

|||

|

Quote:

Think about the two relative forces trying to act getting through those tiny radial holes... one pressurized fluid ( almost no compression happening there although fluids can compress close to one percent ... we use the phrase ' non compressibility of fluids loosely when describing brake systems since it has no visible effect )... and the other AIR... easily compressible... so the difference between shooting stuff through those holes.. fluid one direction and air the other... I see almost no air flow given that it is a closed small chamber and the other three strokes of the piston will not be trying to put air into the precombustion chamber at all...Or any way to sweep it out given that it is a closed system with regards to air .... even the other piston upstroke the exhaust valve is open...and air is a liquid in that is flows to the least resistance...

__________________

1980 240d , chain elongation, cam marks reference: http://www.peachparts.com/shopforum/showthread.php?threadid=10414 http://www.peachparts.com/shopforum/diesel-discussion/305365-9-degrees-chain-stretch.html evap fin cleaning: http://www.peachparts.com/shopforum/diesel-discussion/156207-photo-step-step-post-showing-w123-evaporator-removal-1983-240d-1982-300td.html?highlight=evaporator A/C thread http://www.peachparts.com/shopforum/diesel-discussion/297462-c-recommendations-mb-vehicles.html |

|

#27

|

|||

|

|||

|

Quote:

Then it occurred to me that with the engine all bolted and sealed up... it would seem like the wrong time to do it.... Usually this fine a measurement of that head dome volume would be FOR the purpose of making all cylinders have the same compression ratio... so differences could be adjusted right then with a grinder or EDM... but to check it with it all buttoned up just seems futile.... LOLOL And it does introduce that ' leaking from the bottom' concept into an otherwise very accurate way to find the total capacity of the combustion chamber...

__________________

1980 240d , chain elongation, cam marks reference: http://www.peachparts.com/shopforum/showthread.php?threadid=10414 http://www.peachparts.com/shopforum/diesel-discussion/305365-9-degrees-chain-stretch.html evap fin cleaning: http://www.peachparts.com/shopforum/diesel-discussion/156207-photo-step-step-post-showing-w123-evaporator-removal-1983-240d-1982-300td.html?highlight=evaporator A/C thread http://www.peachparts.com/shopforum/diesel-discussion/297462-c-recommendations-mb-vehicles.html |

|

#28

|

||||

|

||||

|

Yeah I guess it is safer to try to measure these volumes when the engine is in bits - I see nobody has suggested using a balloon; stuffing it into the volume and filling it with oil!

Slightly different subject:- I was thinking about petrol engines the other day, where lots of old straight six engines (in Europe) used to be modified with the addition of a single carburettor for each cylinder instead of using just one large one for the whole engine. Ford Zodiacs (European model http://en.wikipedia.org/wiki/Ford_Zodiac#Mark_I) were famous for this - you got more power and better economy in return for the nightmare of balancing 6 carburettors! My OM617 is a little like this in the way that everything is set up for the ideal single situation - perhaps a system that was tuned to each cylinder size would yield benefits?

__________________

1992 W201 190E 1.8 171,000 km - Daily driver 1981 W123 300D ~ 100,000 miles / 160,000 km - project car stripped to the bone 1965 Land Rover Series 2a Station Wagon CIS recovery therapy! 1961 Volvo PV544 Bare metal rat rod-ish thing I'm here to chat about cars and to help others - I'm not here "to always be right" like an internet warrior Don't leave that there - I'll take it to bits! |

|

#29

|

|||

|

|||

|

Quote:

I used to make quite a bit of money converting the Z1000 motors to run off a single SU carb.... and then flogging the Z1000 carbs to people tuning mini's... lol |

|

#30

|

||||

|

||||

|

20 Years ago, my dad invented a tester for re-perfusion of tissue to measure vascular damage- it would squeeze fluid out of say, your finger and relax the pressure and measure in increase in volume of your finger over time. Resolution was a few CC's or so.

Used the ideal gas law. Pumped up a hi pressure reservoir and used solenoid valves to fill and vent a section of tubing, and measure the pressure change on the vented side of the known volume of tubing. In simplified form: Tube A with Va is between solenoid valves A and B, the test section is after solenoid A, and a pressure sensor can be between the solenoids or after solenoid B. The tank would pressurize to P1, solenoid A opens then and the tube A is at P1. Solenoid B opens, air flows into the test section and the pressure is measured P1V1 = P2 (measured) V2 (this is V1 + unknown volume).

__________________

CC: NSA All things are burning, know this and be released. 82 Benz 240 D, Kuan Yin 12 Ford Escape 4wd You're four times It's hard to more likely to concentrate on have an accident two things when you're on at the same time. a cell phone. www.kiva.org It's not like there's anything wrong with feeling good, is there? |

|

| Bookmarks |

|

|