|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

LinkBack | Thread Tools | Display Modes |

|

#16

|

||||

|

||||

|

IIRC,

There used to be a MBZ tool that screwed into the BLOCK near the timing device and locked the engine from rotating.....617 engine of course...

__________________

1978 300SD 'Phil' - 1,315,853 Miles And Counting - 1, 317,885 as of 12/27/2012 - 1,333,000 as of 05/10/2013, 1,337,850 as of July 15, 2013, 1,339,000 as of August 13, 2013 100,000 miles since June 2005 Overhaul - Sold January 25th, 2014 After 1,344,246 Miles & 20 Years of Ownership

|

|

#17

|

||||

|

||||

|

Diesel911, great write-up and pics, it helped me a lot in getting started in loosening the 4 IP mounting bolts for the upcoming IP timing adjustment.

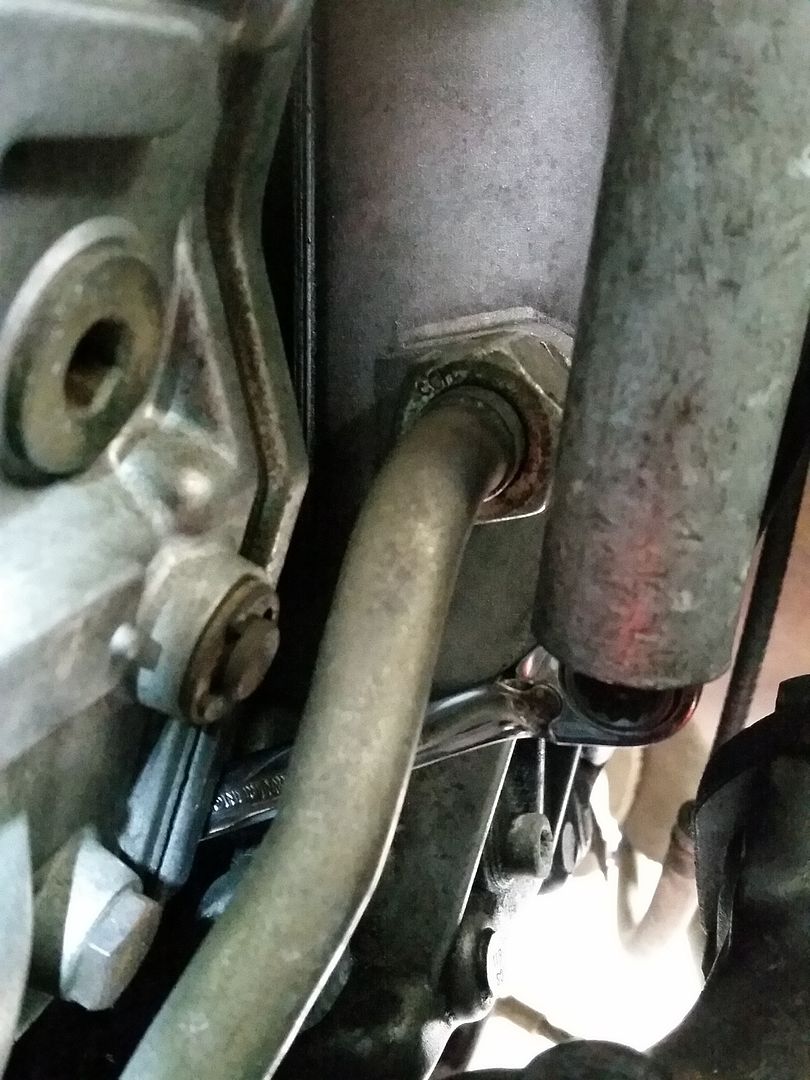

I was able to break free and loosen the rear bolt without removing the oil filter housing pipes or the rack damper bolt. You're right that the rack damper bolt blocks the view of said bolt, but I was able to see it by looking straight down between engine block and the oil filter housing (this is absolutely necessary in order to place the gear wrench on the bolt). Here is a pic of the gear wrench in place, with a pipe resting on it which I hammered on with a mallet to break it free. The hardest bolt to loosen for me was actually the front bolt between IP and block, which I had to get the wires out of the way to maneuver the 13 mm socket on a 3/8" wobble extension/ratchet.  This is the Gear Wrench bought from Lowes, it has 4 sizes 8,10, 12, 13 mm. It is straight and not angled like most gear wrenches and sits on the bolt squarely without shifting. Real handy wrench to have.  Quote:

__________________

85 300D turbo pristine w 157k when purchased 161K now 83 300 D turbo 297K runs great. SOLD! 83 240D 4 spd manual- parted out then junked Last edited by funola; 05-08-2016 at 11:59 PM. |

|

#18

|

|||

|

|||

|

When I installed the SuperPump I was able to get the bolts loose with only minor heartburn but I could NOT slide the old pump back far enough with the filter housing in place. It wasn't TOO bad to remove and replace the housing though it did fight me here and there. Getting the first filter housing bolt started was the hardest part.

Interesting side note: When I pulled the housing oil, of course, went all over the place. I had a pan under there but it seemed like the oil went everywhere the pan was not. So I cleaned the flanges, installed a new gasket, and bolted everything back together. No leaks but the weird part was that the oil level wasn't down at all! Evidently I didn't lose all that much even though it looked like the oil equivalent of a murder scene. Dan |

|

#19

|

||||

|

||||

|

Why was it difficult to get the first filter housing bolt started? Would it help if one of the bolts was replaced with a stud and a nut? Is that possible?

Next time, remove the oil filter housing lid fasteners and lift it up an inch before you remove the oil connections. I believe that will drain the housing.

__________________

85 300D turbo pristine w 157k when purchased 161K now 83 300 D turbo 297K runs great. SOLD! 83 240D 4 spd manual- parted out then junked |

|

#20

|

|||

|

|||

|

Quote:

I thought of pulling the filter element and draining the canister but didn't think it would leak all that much. I was wrong! Dan |

|

#21

|

||||

|

||||

|

Quote:

__________________

84 300D, 82 Volvo 244Gl Diesel |

|

#22

|

|||

|

|||

|

trying to pull the IP for gasket replacement...

On my '79 240D I can't even get to the cap screws. Sure, the rear one comes off...I got under the car and finally removed the bottom cap screw on the support bracket....

But some Rhodes Scholar installed the upper bracket cap screw in spite of the fact that a normal socket will not go over the head an account of the head of the cap screw being too close to the bend in the bracket. A follow-up search of the web showed the thin-wall 13mm socket difficult to find, although I know they are out there. I considered Diesel911's suggestion about the slot, but the bracket remains in the way if the slot is added, and the IP cannot move back to be removed with this bracket in place. Couldn't this exercise be a little easier by replacing all 3 of those cap screws with Allen head fasteners? Wouldn't it be easier to use a ball-end Allen wrench on these fasteners? Time will tell, I'll pick up a few of the correct size and try them out. I spent far too much time yesterday assuming inverted gymnastic positions attempting combinations of sockets, combination wrenches, extensions.... it just seems a ball-end Allen could negotiate the path to the fastener locations a lot easier. And this is on a 240D! With the A/C removed! From underneath, you can get only one hand on the wrench. I'll go ahead and try this and report back on the results. To me it's a head-scratcher- why didn't Mercedes try this? It's not that Allen or "triple-square" fasteners are unfamiliar to them... Cheers! snapped_bolt

__________________

'81 240D For now, a good place to borrow new parts '80 300TD Probably will be put back into service! '79 240D BACK IN SERVICE SINCE 09/16; limited use, oil leak. Guide pin r/sealed/replaced. Still a leak. Front crank seal.... |

|

#23

|

||||

|

||||

|

Quote:

Are you speaking the absolute upper capscrew that bolts the Fuel Injection Pump to the rear bracket that bolts the Fuel Injection Pump to the rear bracket or one of the 2 block to rear lower bracket capscrews. In the Manual in order to get at the absolute upper capscrew on a 617.952 rear lower bracket it has to remove the Oil Cooler Hose that blocks the view and range of moation of a wrench. When it is time to re-assemble that hard to get at capscrew you will find if you put enough flat washers under it you can fix it so the head of the Cap screw has enough protrusion to get a wrench on.

__________________

84 300D, 82 Volvo 244Gl Diesel |

|

#24

|

|||

|

|||

|

All three...

Just to allow removal, which should be easier, inserting an Allen key rather than wedging in a box wrench or socket...

snapped_bolt

__________________

'81 240D For now, a good place to borrow new parts '80 300TD Probably will be put back into service! '79 240D BACK IN SERVICE SINCE 09/16; limited use, oil leak. Guide pin r/sealed/replaced. Still a leak. Front crank seal.... |

|

| Bookmarks |

|

|