|

|

|

|

|

|

|

|

|

|

|

#1

|

||||

|

||||

|

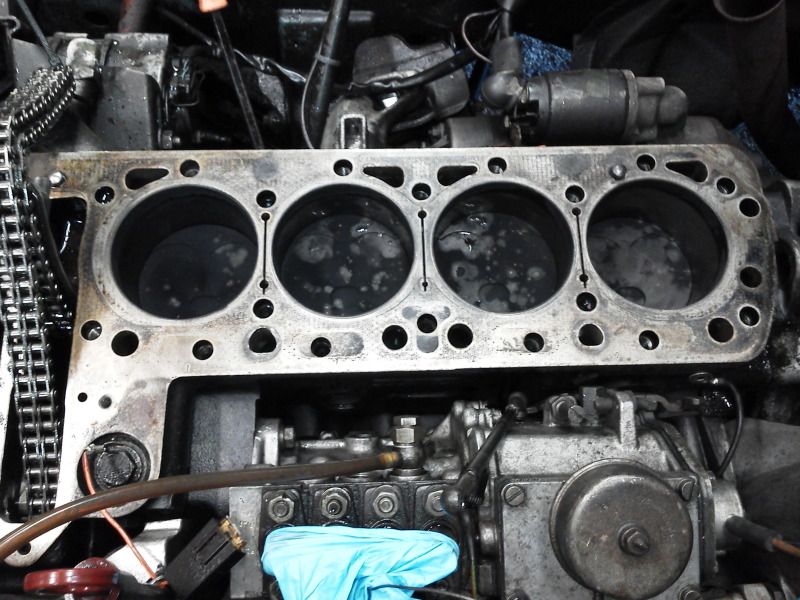

1980 240D CRACKED cylinder head + cavitation damage

There was no piston or cylinder sleeve damage..

The cratering and cracking pictures are in post# 3. .    . Last edited by whunter; 09-09-2012 at 09:30 AM. |

|

#2

|

||||

|

||||

|

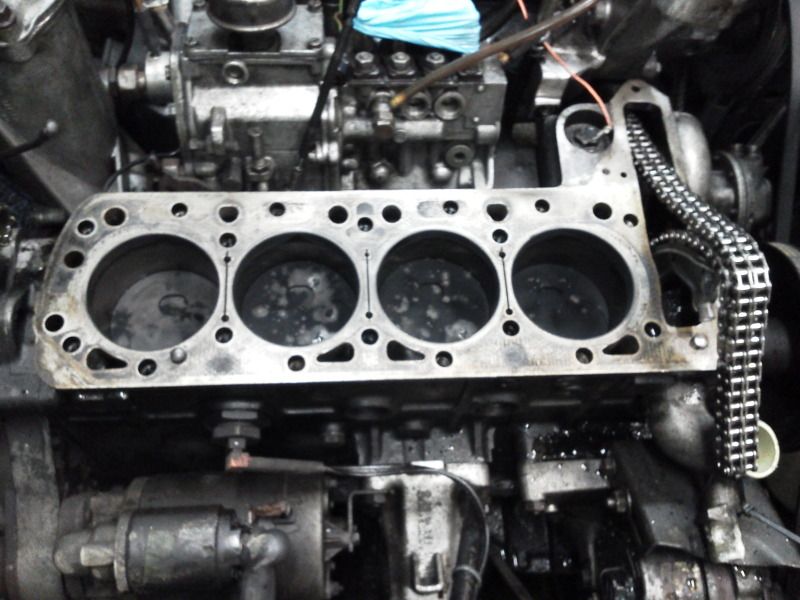

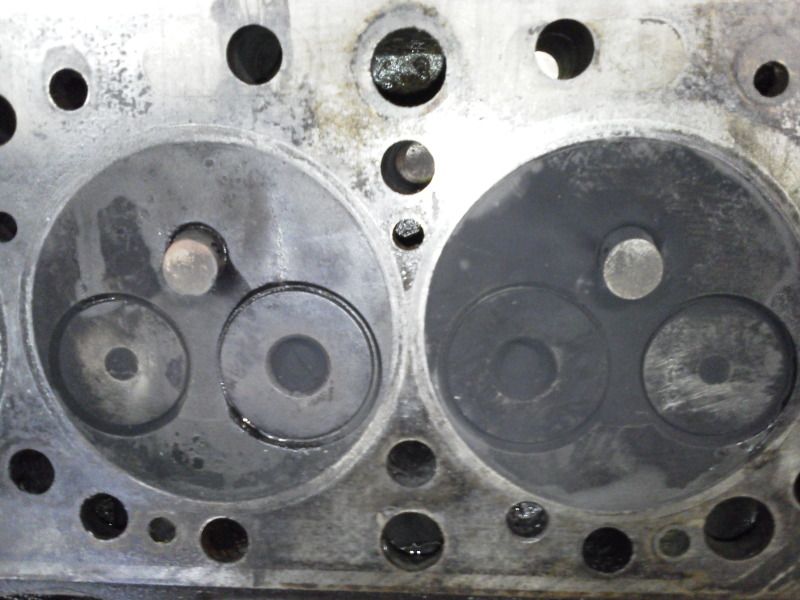

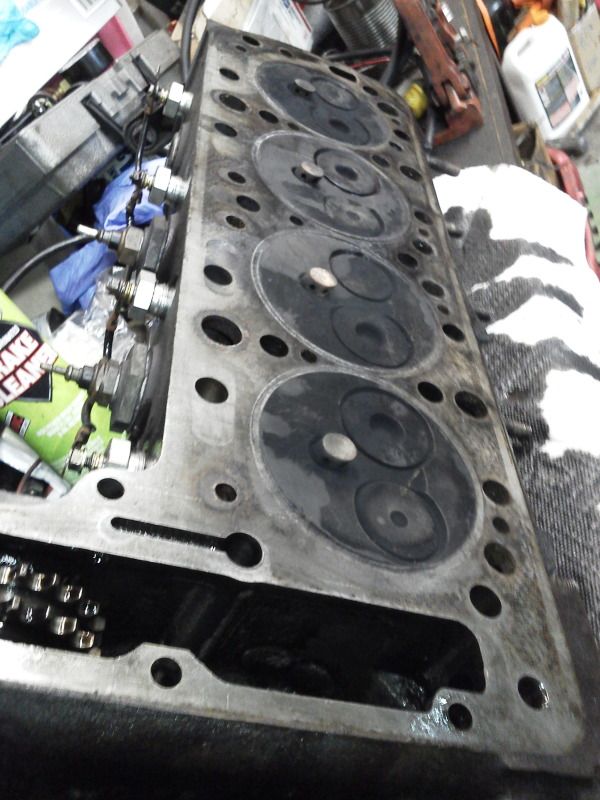

Before cleaning the head face

Here are pictures of the old damaged cylinder head.

.

|

|

#3

|

||||

|

||||

|

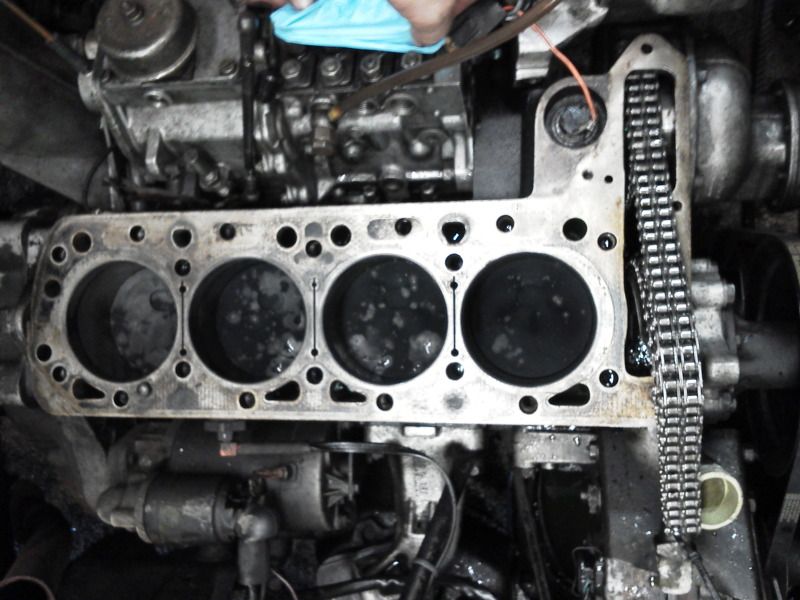

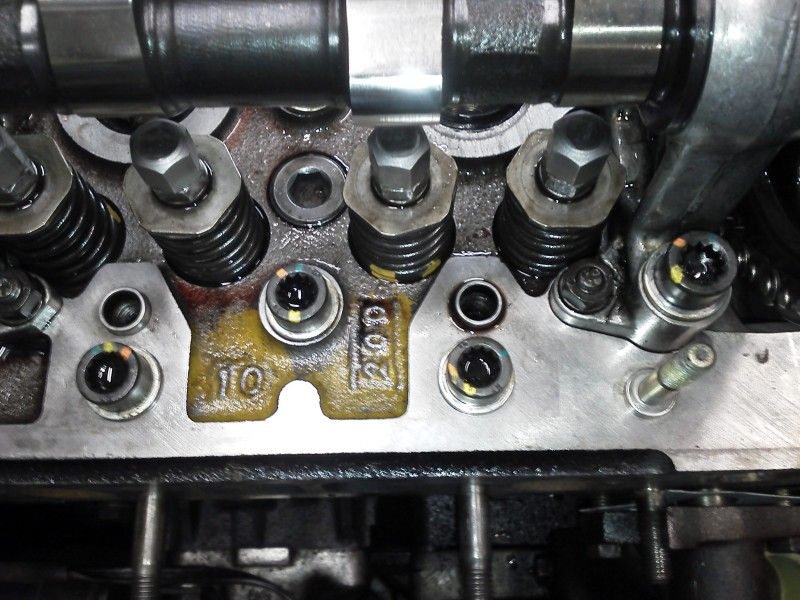

The bad news

Last edited by whunter; 09-08-2012 at 11:53 PM. |

|

#4

|

||||

|

||||

|

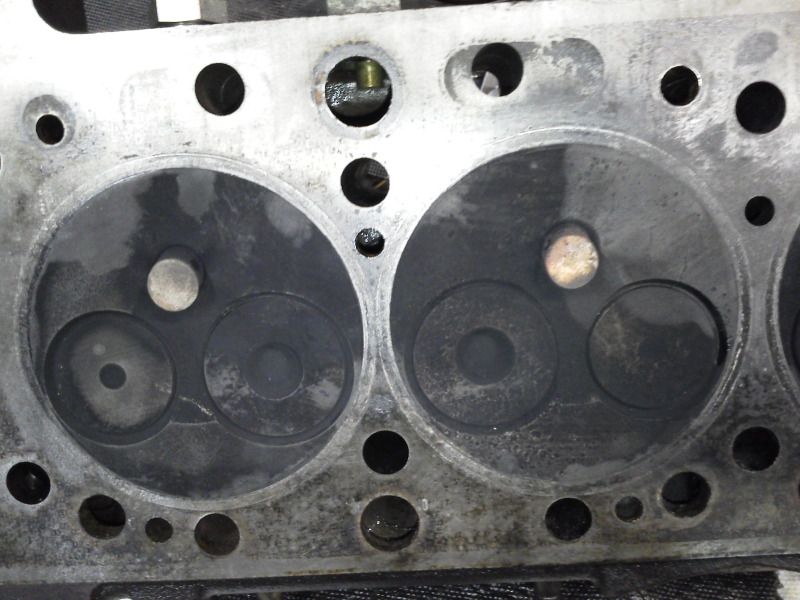

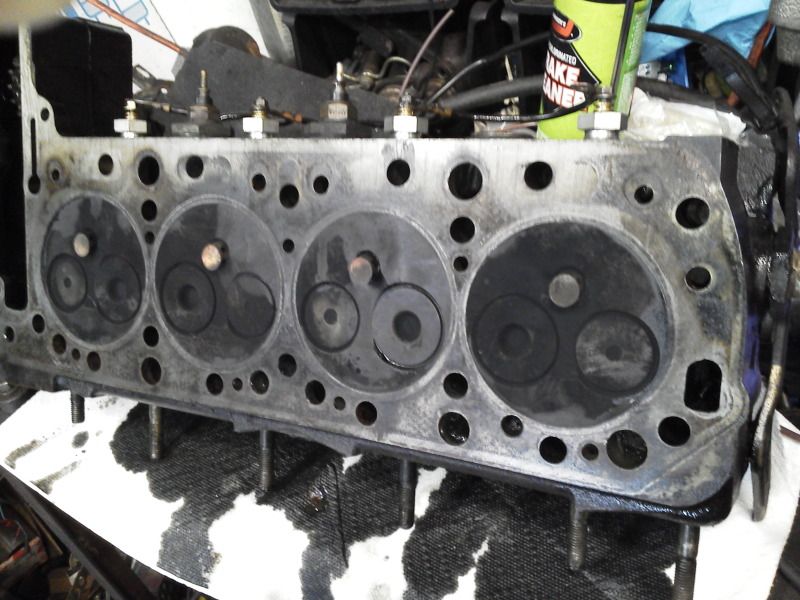

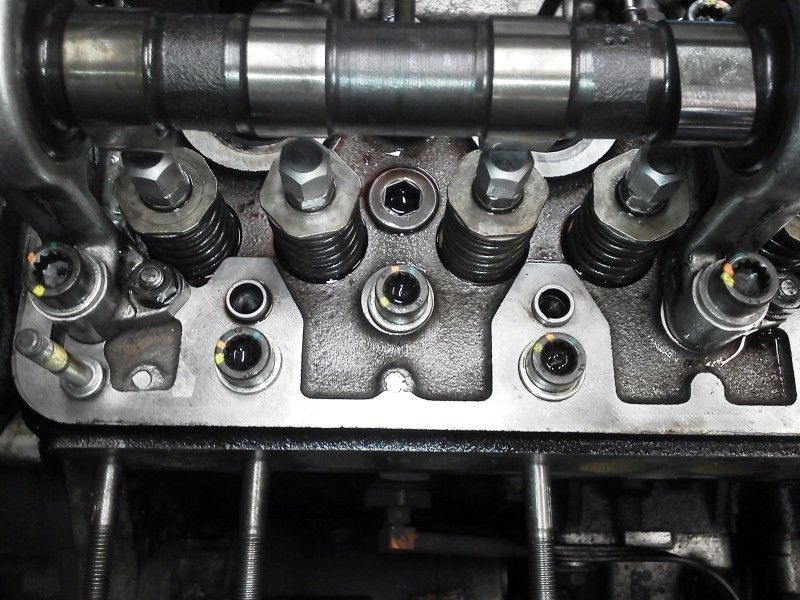

The good news

I had a good used cylinder head, and the parts to rebuild it.

Here are pictures of it. .     . Last edited by whunter; 09-08-2012 at 11:46 PM. |

|

#5

|

||||

|

||||

|

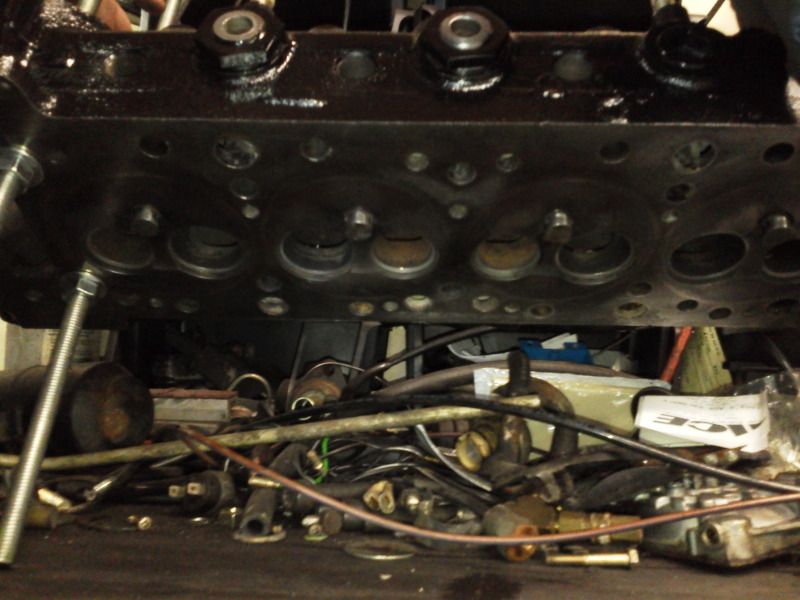

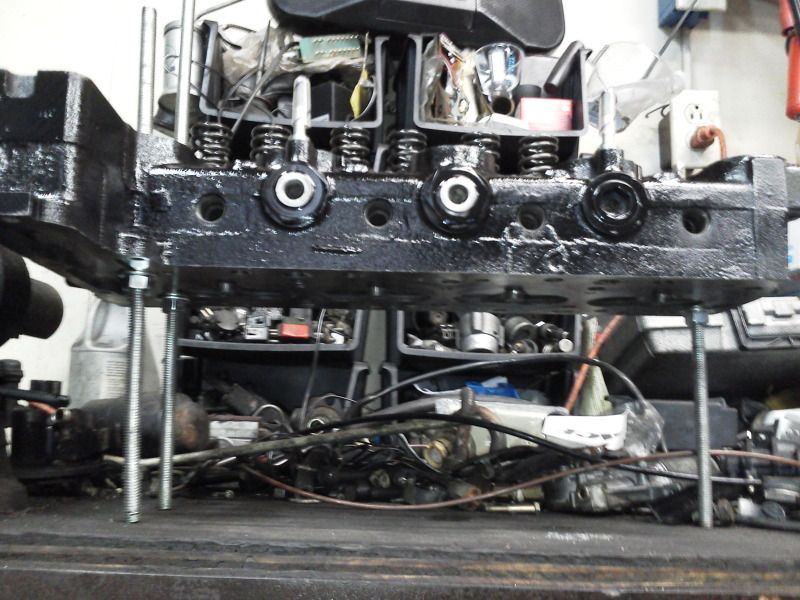

Update

The cylinder head is back on the engine, but not bolted down yet.

. |

|

#6

|

|||

|

|||

|

Roy, 1980 was the yr MB went to the pencil Glow Plugs. I notice this head has the old Loop style. this engine was either replaced, or an early 80 and MB was using the last of the older engines?

Our 80 240 has the pencil GP, and the production date of 12/79. Thank You for posting the pictures. Charlie

__________________

there were three HP ratings on the OM616... 1) Not much power 2) Even less power 3) Not nearly enough power!! 240D w/auto Anyone that thinks a 240D is slow drives too fast. 80 240D Naturally Exasperated, 4-Spd 388k DD 150mph spedo 3:58 Diff We are advised to NOT judge ALL Muslims by the actions of a few lunatics, but we are encouraged to judge ALL gun owners by the actions of a few lunatics. Funny how that works |

|

#7

|

|||

|

|||

|

Thanks for the links on cavitation, very interesting.

I know about cavitation in water pumps, but never heard of it occurring in the water jacket around cylinder walls. Your pictures show the typical cracks that can form on 615, 616, 617 heads. What relation does this kind of damage have to cavitation?

__________________

76 240 D. Bought in 1998 for $25. 85 300D. Got it for free with a bad engine. ( Sold ) 60 Unimog 404. What was left of it, was given to me. Now powerd by 617A. 88 560 SEL. Bought without engine and trans. Now powerd by 617A. 67 250 SE. Cuope. For resto or sale. 64 220SE. For resto. |

|

#8

|

||||

|

||||

|

I am quite familiar with cavitation since I have a Ford truck with a 7.3 IDI in it. I use an anti-cavitation additive init it called DCA-4 to prevent water jacket cavitation. I have read here that this kind of cavitation is not an issue with OM61x engines but these pictures have me concerned. As recommended to be by the majority of people, I am running Zerex G05 coolant in my OM617. As far as I know, it does not have any anti-cavitation additives in it. There is likely nothing that can be done to prevent cavitation in the cylinder bore area but I wonder if the same thing is happening in the water jackets.

I have to look again, but if the Zerex G05 is a low silicate formula, I should be able to add DCA-4 without issue. Thoughts?

__________________

1991 F250 super-cab 7.3 IDI. (rebuilt by me) Banks Sidewinder turbo, hydroboost brakes, new IP and injectors. 2003 S430 - 107K 1983 300SD - Tanoshii - mostly restored ~400K+. 1983 300SD - Good interior. Engine finally tamed ~250K. Monark Nozzle Install Video - http://tinyurl.com/ptd2tge |

|

#9

|

||||

|

||||

|

As a 7.3 IDI motor owner this thread caught my eye, too. My old Ford has over 350k on it, running the anti-cavitation fluid since new. Can this be a problem with the 61x motors due to the type of coolant, or is it more age related?

__________________

1985 300D-189k The 'UD', Ivory and Pinkamino 1979 300D-211k Dark Gray, Parchment A 1980 Harley-~166k and A 1994 Ford diesel pickup-349k and A 1990 gasser Volvo wagon-145k |

|

#10

|

||||

|

||||

|

Answer

Quote:

. |

|

#11

|

||||

|

||||

|

More pictures

Torquing the new cylinder head

Torquing the new cylinder head pictures by whunter - Photobucket Please note the paint dots on the bolt heads.. This is a procedure used in R&D prototype, where a mistake can cost millions. Tighten the fastener and paint mark it, if there is more than a one step one torque = use a different color for each torque step. There are FOUR torque steps on the OM616 cylinder head bolts = four color dots on each bolt head. The procedure is elegant: #1. Torque the fastener. #2. Paint mark the fastener. #3. Go to the next fastener.   As I recall the OM616 requires: Quantity Four 115 MM bolts. Quantity Eight 120 MM bolts. Quantity Six 145 MM bolts. . Last edited by whunter; 02-15-2013 at 03:51 AM. |

|

#12

|

||||

|

||||

|

Update

24 hours after this repair.

Before this repair: #. The engine was full throttle at 70 mph, with little or no reserve power. #. It was difficult to cold start at 70° F, occasionally requiring two full glows. #. There was a random light - medium nailing that could not be pinned down. #. Coolant temperature averaged 90° C, no detectable fluid loss. #. Idle set screw was adjusted all the way in to get a stable 1000 rpm idle. After replacing the cylinder head: * The engine cold starts in 5 - 15 seconds without glow plugs at 54° F. * Coolant temperature 80° C.. * Walking around the running car, you can feel the authoritative basso compression - firing thump of a fresh engine. * Required throttle has reduced roughly 50% for the same power. * Idle was 1200 rpm on first start, and has been adjusted - lowered to 650 rpm. . |

|

#13

|

||||

|

||||

|

Those are some very nice looking valve adjustment nuts !

Do you know what the thread is on them ?

__________________

1985 300D 198K sold 1982 300D 202K 1989 300E 125K 1992 940T "If you dont have time to do it safely, you dont have time to do it" "The democracy will cease to exist when you take away from those who are willing to work and give to those who would not." |

|

#14

|

||||

|

||||

|

Bump

for member "joshgold10"

.

__________________

ASE Master Mechanic asemastermechanic@juno.com Prototype R&D/testing: Thermal & Aerodynamic System Engineering (TASE) Senior vehicle instrumentation technician. Noise Vibration and Harshness (NVH). Dynamometer. Heat exchanger durability. HV-A/C Climate Control. Vehicle build. Fleet Durability Technical Quality Auditor. Automotive Technical Writer 1985 300SD 1983 300D 1984 190D 2003 Volvo V70 2002 Honda Civic https://www.boldegoist.com/ |

|

#15

|

|||

|

|||

|

how does cavitation inside the water jacket cause cratering and cracking in the combustion chamber? or is the water cavitation so severe, that it eroded all the way through the metal and into the combustion chamber?

|

|

| Bookmarks |

|

|