|

|

|

|

|

|

|

|

|

|

|

#16

|

||||

|

||||

|

Quote:

You can try and Mityvac but the results may not be conclusive since the pinhole can be very small. .

__________________

85 300D turbo pristine w 157k when purchased 161K now 83 300 D turbo 297K runs great. SOLD! 83 240D 4 spd manual- parted out then junked |

|

#17

|

||||

|

||||

|

OK

Quote:

Each post will cover one issue. FYI: The fuel sender has been superseded four times, and alternative level verification may be needed. The current part is MB# 2105424017 * You have replaced the fuel tank Screen. FYI MB diesel filtration, how it works. MB diesel filtration, how it works. - PeachParts Mercedes ShopForum .

__________________

ASE Master Mechanic asemastermechanic@juno.com Prototype R&D/testing: Thermal & Aerodynamic System Engineering (TASE) Senior vehicle instrumentation technician. Noise Vibration and Harshness (NVH). Dynamometer. Heat exchanger durability. HV-A/C Climate Control. Vehicle build. Fleet Durability Technical Quality Auditor. Automotive Technical Writer 1985 300SD 1983 300D 1984 190D 2003 Volvo V70 2002 Honda Civic https://www.boldegoist.com/ |

|

#18

|

||||

|

||||

|

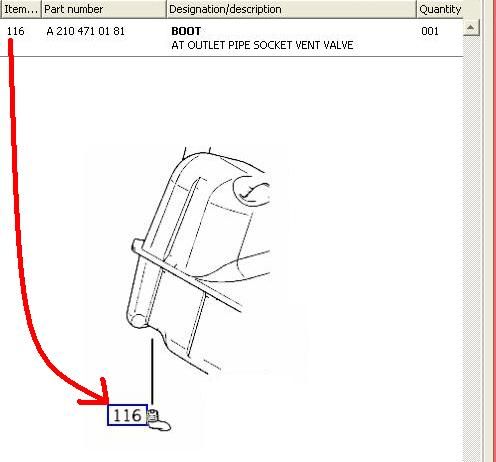

Vacuum in the fuel tank

What is this valve and why is it dripping diesel?

What is this valve and why is it dripping diesel? Fuel tank vent pictures + location 93 300D 2.5L Turbodiesel Power Loss What happens when a tank vent gets clogged. What happens when a tank vent gets clogged. - PeachParts Mercedes ShopForum Imploded fuel tank - so sad! Imploded fuel tank - so sad! Why do I have vacuum in my diesel tank.....................? Why do I have vacuum in my diesel tank.....................? - PeachParts Mercedes ShopForum . |

|

#19

|

||||

|

||||

|

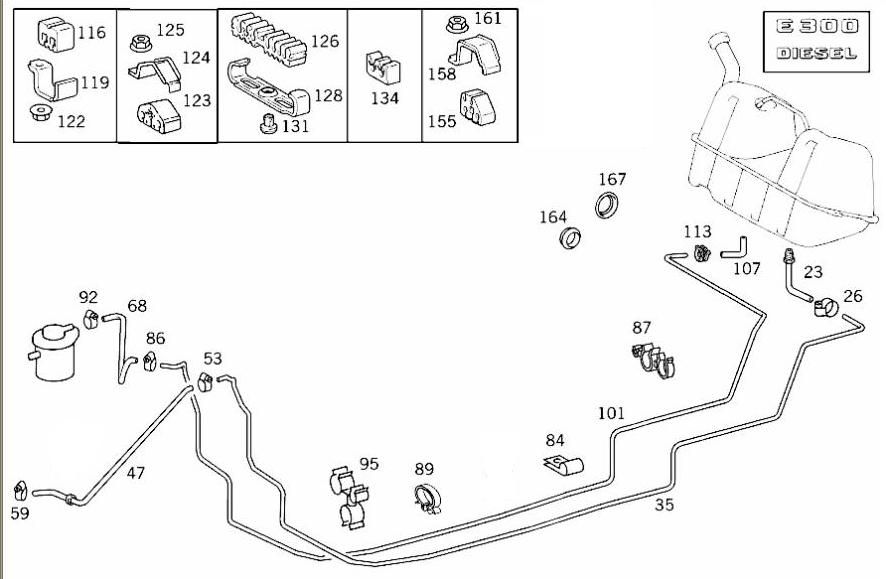

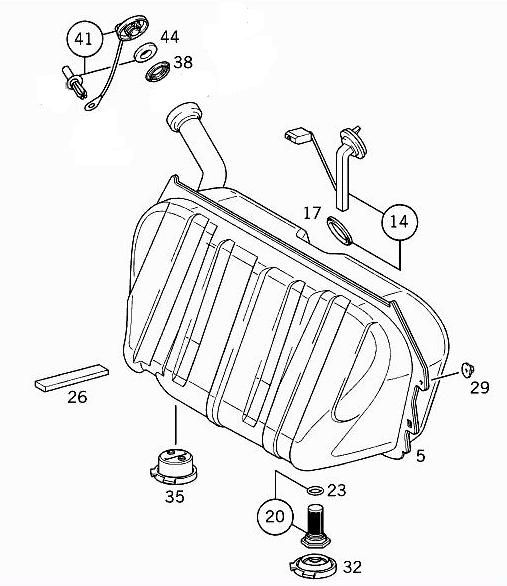

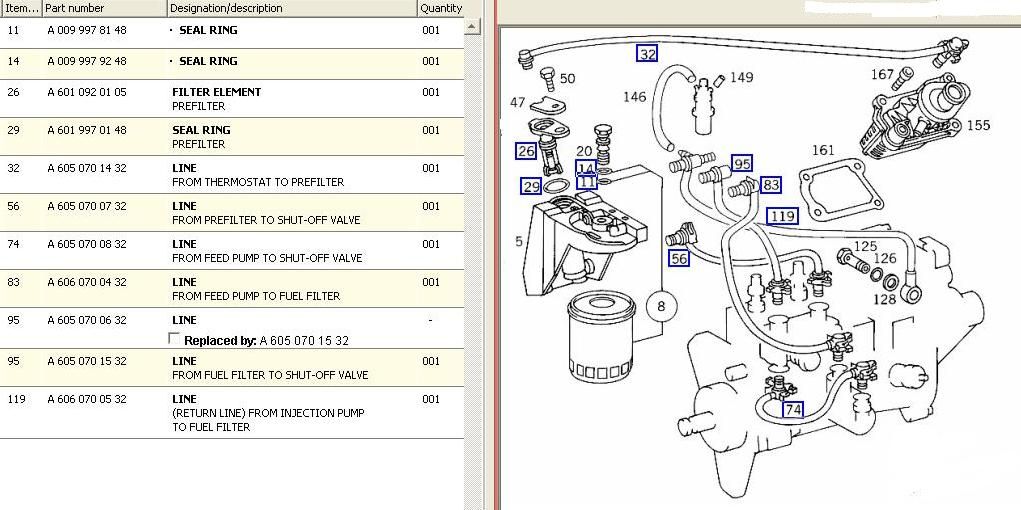

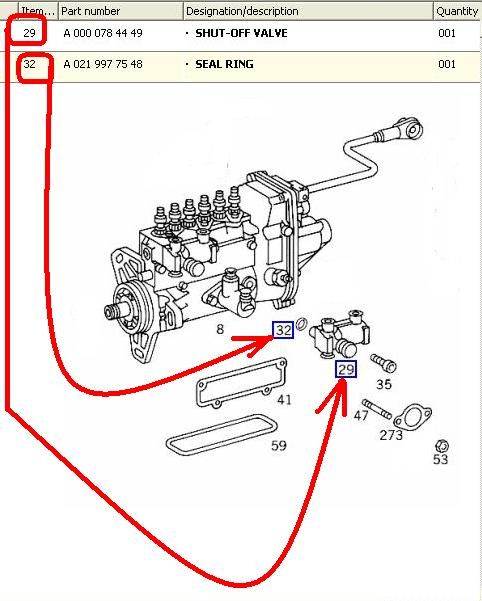

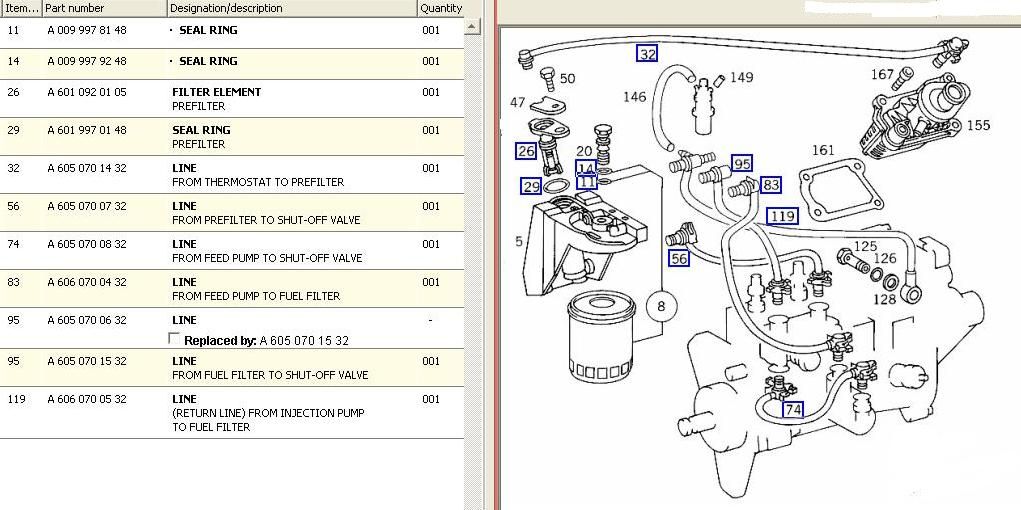

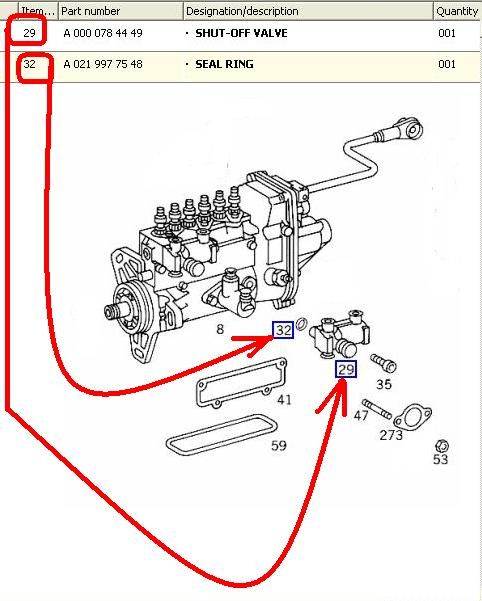

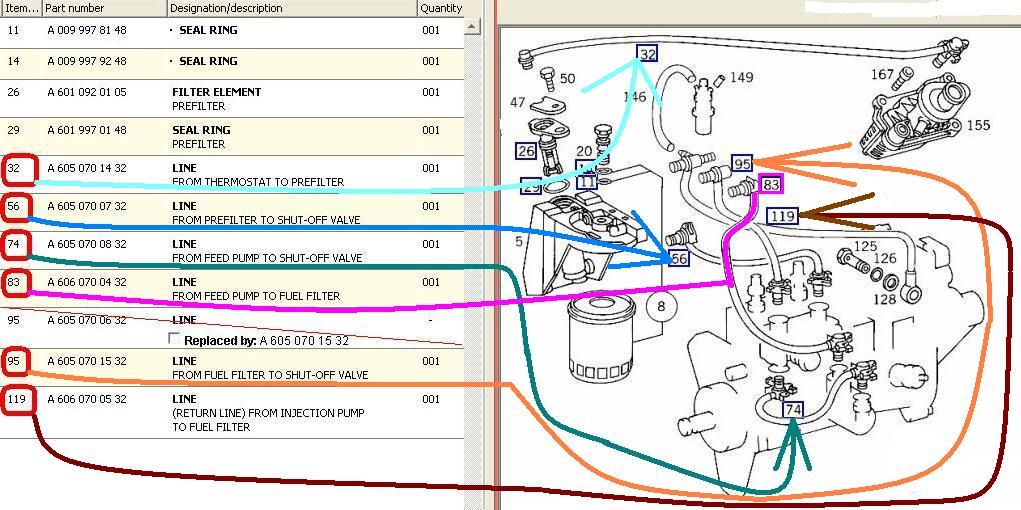

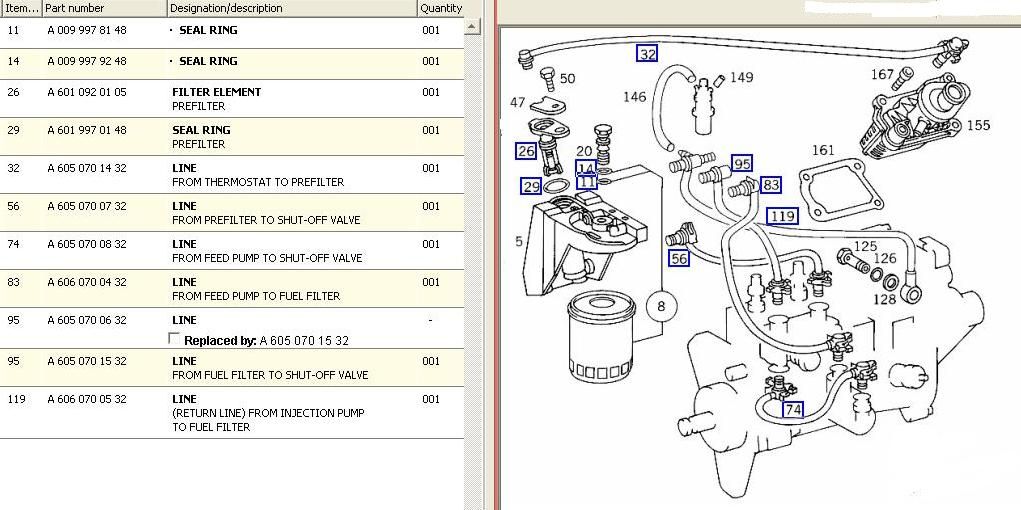

Fuel system pictures

These include the injection pump.

. |

|

#20

|

||||

|

||||

|

Someone will mention this one

I seriously doubt it could be related to your symptoms.

OM60_series IP delivery valve reseal OM60_series IP delivery valve reseal . |

|

#21

|

||||

|

||||

|

Most common issue

The most common issue is bad O-rings.

.  The shutoff valve O-ring is overlooked - missed all the time. .  The nylon fuel lines become ugly coffee color due to microscopic cracks/abrasion/age, and the O-rings on each end fail.  Item #26 pre-filter element is known to distort with age, causing mild to no start issues. Note: The associated O-ring must be replaced at the same time, for similar reasons. .  The screw on fuel filter BOLT has O-rings that need to be inspected at each new filter, and replaced every 2 - 3 filters. On rare occasion, the shutoff valve may crack. .

__________________

ASE Master Mechanic asemastermechanic@juno.com Prototype R&D/testing: Thermal & Aerodynamic System Engineering (TASE) Senior vehicle instrumentation technician. Noise Vibration and Harshness (NVH). Dynamometer. Heat exchanger durability. HV-A/C Climate Control. Vehicle build. Fleet Durability Technical Quality Auditor. Automotive Technical Writer 1985 300SD 1983 300D 1984 190D 2003 Volvo V70 2002 Honda Civic https://www.boldegoist.com/ Last edited by whunter; 11-22-2012 at 03:43 AM. |

|

#22

|

|||

|

|||

|

I've replaced shut off oring also all the dv rings all the fuel lines and much more. I'm pretty confused by this post...how can I specifically diagnose my problem? Old the vent be a symptom?

|

|

#23

|

||||

|

||||

|

Answer

Quote:

.

__________________

ASE Master Mechanic asemastermechanic@juno.com Prototype R&D/testing: Thermal & Aerodynamic System Engineering (TASE) Senior vehicle instrumentation technician. Noise Vibration and Harshness (NVH). Dynamometer. Heat exchanger durability. HV-A/C Climate Control. Vehicle build. Fleet Durability Technical Quality Auditor. Automotive Technical Writer 1985 300SD 1983 300D 1984 190D 2003 Volvo V70 2002 Honda Civic https://www.boldegoist.com/ |

|

#24

|

|||

|

|||

|

What about the Lift Pump?

I'd think about checking or changing out the mechanical lift pump, especially if you have high mileage on the engine and have replaced all the o-rings. I had a similar situation happen to me on my '87 diesel ..... sluggish running and it would quit with about a 1/4 tank of fuel remaining. The lift pump worked but it was weak ... so when the fuel ran low the pump couldn't produce enough fuel pressure to keep everything running. I replaced the lift pump and all was fixed. Additionally, on the OM606 motors it is possible to mix up the fuel lines when replacing the o-rings and then things don't run right either ... so double check that everything is hooked up correctly as per the diagrams previously provided. Good Luck!

|

|

#25

|

|||

|

|||

|

What is the cost on something like that? In fact are these lift pumps testable?

|

|

#26

|

|||

|

|||

|

Also I feel this important.... If I am parked at an incline where the tank be higher than the engine, it runs idles but if u level out it dies after minutes

|

|

#27

|

||||

|

||||

|

FYI

Quote:

.

__________________

ASE Master Mechanic asemastermechanic@juno.com Prototype R&D/testing: Thermal & Aerodynamic System Engineering (TASE) Senior vehicle instrumentation technician. Noise Vibration and Harshness (NVH). Dynamometer. Heat exchanger durability. HV-A/C Climate Control. Vehicle build. Fleet Durability Technical Quality Auditor. Automotive Technical Writer 1985 300SD 1983 300D 1984 190D 2003 Volvo V70 2002 Honda Civic https://www.boldegoist.com/ |

|

#28

|

|||

|

|||

|

I'm sure there is a test proceedure out lined somewhere along with a special guage to read the pressure output of the pump ..... but if the car idles fine on a negative incline (fuel in the tank higher than injector lines) and dies with the fuel level below the injection pump, plus the fuel filters are new and the lift pump has more than 150k miles on it, that would be enough evidence for me (shade tree mechanic) to replace the lift pump. Good Luck!

|

|

#29

|

|||

|

|||

|

Any specifics on howto apply vacuum for a leak check? Does tank need to be empty? Please this car is 500 miles from home and it's stranded!!

|

|

#30

|

|||

|

|||

|

Quote:

Get a couple of 3' sections of clear vinyl tubing I'm pretty sure 3/8" ID will fit, Home depot sells 15' rolls for about $5. Then you get a couple liter empty clean soda bottle or some similar sized plastic container, clear if you can because that will allow you to observe both the rate of fuel return and whether it is a solid stream or filled with bubbles. Mark the hose and the steel fuel lines so you can get them back to where they belong when your done and separate them where they meet in the engine compartment. Be ready to plug the fuel inlet line because if there is much fuel in the tank it will run out until the level drops low enough. A short 3 inch section of hose that has been plugged with a bolt or even a whittled stick will work fine. Get that apart and close off that line with your plug. Do the same with the fuel return line. Now you have the fuel supply separated from the engine. Now you take your clear vinyl hose and using about 3 feet of it connect it to the fuel return outlet up at the secondary filter. Should be a hose bib and a hose clamp attachment there. Then take a second 3 foot section of clear vinyl and attach it to the inlet of the primary filter, should be a hose clamp that attachment there also. Then get your soda bottle or whatever plastic vessel you have that you can squeese into place along side the engine on that IP side area, might need to use a piece of wire, string, duct tape ariound the neck of the bottle to secure it from falling down too far or falling over and spilling. But figure out the how and where placement of it. With that done pull the bottle out and fill it about 2/3 with fresh diesel, place the bottle into the pre-determined position and secure it from falling or dropping. Place the two clear vinyl hoses, one from the return and the other one to the primary filter, place their ends down into the diesel. You probably will want to use a bit of tape, wire, string to hold the tubing in place at the bottle mouth particularly it the engine starts and runs and you want to drive around the block. You effectively created a alternative mini fuel system attached to the engine, with that hopefully you can get the car started and determine whether your problem is with the IP/filter/lift pump system or with the fuel delivery system. If the car starts and runs you should be able to drive around the block (actually a couple miles) with it set up like that. If you find the problems with running and dying that you've described have not been eliminated then the problem is not the fuel supply side of the equation. But you need to separate the two systems to identify where to focus your efforts. With the bottle of fuel you know that the fuel supply is not in question so it can by seeing if the engine runs and drives eliminate the engine side of the equation. If you get that done then you can focus the future effort on what needs to happen to get things right. To answer the specific question you posted, as far as testing the steel underchassis fuel supply line, you plug one end and apply vacuum to the other end, and see if it holds vacuum or not. For your vehicle you would need to clamp off the flexible hose attached to the tank's fuel strainer, remove the hose clamp securing the other end of the flexible hose to the steel underchassis fuel line and separate the two, disconnect the flexible fuel hose between the end of the steel line and the primary filter, then remove the fuel from the steel line by blowing it out using just a couple foot section of hose to attach to the steel line and blow in catching the fuel at the other end, fashion some type of plug and seal one end of the steel line and then apply vacuum to the other end and observe whether it holds the applied vacuum. |

|

| Bookmarks |

|

|