|

|

|

|

|

|

|

|

|

|

|

#1

|

|||

|

|||

|

w123 240D rough idle

Hello

Recently i acquired a rather tired 1983 240D. The engine runs rough. The whole body shakes at idle. So far i have done the following: - Adjusted valve clearance - Replaced both motor mounts with new lemrorder ones - Replaced gearbox/engine mount (so called T mount) - Replaced primary and main fuel filter - Replaced oil filter and oil - Replaced primer pump - Replaced fuel supply hose to primary filter and from primary filter to injection pump base (where the primer pump is) - Replaced return hoses from injectors - Replaced injector nozzles with denso dn0sd261 and had them set to pop at 155bar None of the above made any difference as far as the shaking at idle goes. I tried increasing the idle withe the screw on the back of the injection pump (Bosch M/RSF with mechanical governor) but it only shakes differently. Compression test reads as follows: 1 - 325psi, 2 - 335psi, 3 - 325psi, 4 - 260psi Right now i am suspecting the fourth cylinder to be causing the shaking or the injection pump supplying fuel unevenly to the cylinders. I would be grateful for any suggestions before i pull the head to see if no.4 cylinder has a broken ring or bad head gasket in that area. |

|

#2

|

|||

|

|||

|

You could check the timing.

The 260 psi is too low compared to the other cylinders. Have you done the compression test hot or cold? You could do a compression leak test before you pull the head. A broken ring cannot be diagnosed by just pulling the head. 155 bar is a bit high for a 240D. And isn't the dn0sd261 for the OM601 engine? |

|

#3

|

||||

|

||||

|

155 bar is way to high for a NA 61x engine. The NA engines are supposed to have injectors that are 115bar. 155 in a Turbo engine would be fine, but probably not in a NA. The injection timing will be quite delayed.

Also the 260psi in #4 would cause quite a bit of shaking. They say you're not supposed to have more than 10% differnce. Try soaking that cylinder in Marvel Mystery oil or brake fluid. This will brake up any build up on the piston rings and free them up. This may help. If you use brake fluid plan on draining the oil and putting in fresh, cause the fluid will leak past and drain into the pan. Also did you change the transmission mount, or just the T-mount? They aren't they same thing. I've seen engines shake quite a bit with a tired trans mount. I've never found the T-mount to make any difference. It's a flimsy little piece of rubber. When I change mine in my 240 it did nothing for the shaking.

__________________

Andrew '04 Jetta TDI Wagon '82 300TD ~ Winnie ~ Sold '77 300D ~ Sold

|

|

#4

|

|||

|

|||

|

I did the compression test on a cold engine. After that i put some engine oil in #4 cylinder through the injector hole and gave it some time to leak down into the cylinder. Compression went up from 260psi to 410psi when i put oil in there. I was suspecting stuck rings so i put atf through the injector hole, let it soak for a couple of days, rotated the engine and repeated the process 3 times in 2 weeks. I know i would have to drive it quite some time for the ring to free (assuming it is stuck). Hooking up a compressor to #4 cylinder, supplying a steady pressure and listening where the air escapes is what i need to do next?

155bar is incorrect. It says on the injector body how much it should be. I probably made a mistake typing and it is in fact set to 115bar according to the stamping. Sorry about that. I also named the engine/transmission mount incorrectly as the t mount  . I changed this one: . I changed this one:http://i.ebayimg.com/05/!BsZw,4!Bmk~$(KGrHqYOKjIEvO+VTWcNBL3t+dGeU!~~_1.JPG plus both engine mounts: http://www.mercedesmanuals.com/v/vspfiles/photos/123-241-3013PR-2T.jpg Yes the nozzles are a newer type introduced for 601 engines. They are suposed to run just fine in older engines. In fact i see people everywhere installing these dn0sd261 from boiso and monark brands into om61x engines. they are suposed to be quieter. Also on worn out, old nozzles it shook just as much. Is it ok to rule out any problems with the injection pump? I was thinking of measuring how much fuel returns from each injector when the engine is idling for some time. I would use 4 identical containers to compare. I also failed to mention that the engine has some blow-by. It has a plastic oil cap that will be blown of if you don't hold it. There was oil on the air filter so some of it is going into the housing. Last edited by rydzio; 10-23-2012 at 05:05 AM. |

|

#5

|

|||

|

|||

|

You can repeat the compression test when the engine is fully warmed up to see if that makes a difference.

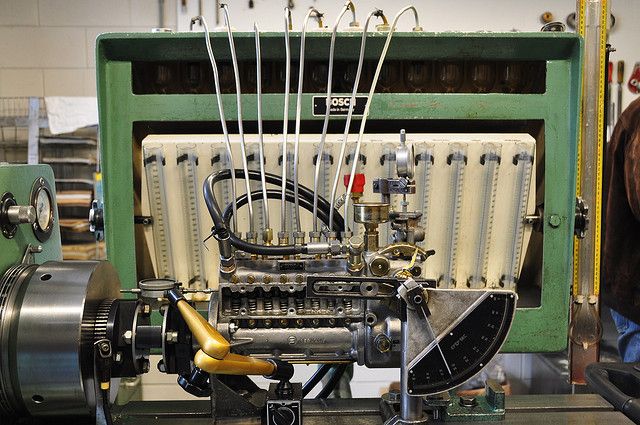

A compression leak test is indeed done with a compressor, but you need a reduction valve, so that the air pressure is lowered to around 2 bar. Ideally you need a gauge, so that you can determine the amount of leakage (in %). Here is a diagram from Wikipedia so you can see how the gauge works: Source: File:Leak down tester.GIF - Wikipedia, the free encyclopedia Injection pump usually lasts several engines, so it is an unlikely candidate, but it is not impossible. Injection pumps are indeed tested in the way you describe, but on a test bank, see the picture below.  Blow by is normal, even non-shaking engines have that. The problem with using nozzles which aren't designed for your engine is that you never know which problems they can cause. Diagnosing problems can be more difficult, because there aren't any specs with which to compare. |

|

#6

|

||||

|

||||

|

Have you measured the idle speed?

__________________

1992 W201 190E 1.8 171,000 km - Daily driver 1981 W123 300D ~ 100,000 miles / 160,000 km - project car stripped to the bone 1965 Land Rover Series 2a Station Wagon CIS recovery therapy! 1961 Volvo PV544 Bare metal rat rod-ish thing I'm here to chat about cars and to help others - I'm not here "to always be right" like an internet warrior Don't leave that there - I'll take it to bits! |

|

#7

|

|||

|

|||

|

Wow i am really impressed with how many replies i get. I would like to thank you all very much.

I do not have a tool to measure idle rpm. I could buy one if it is absolutely necessary. I did adjust the idle from when the engine starts to choke up to quite high rpm when it just shakes with a different amplitude  I will probably find someone with the equipment necessary to do the leak down pressure test. |

|

#8

|

|||

|

|||

|

Reading up on the milli volt method in the archives and applying it may give you some indication of what may be going on. Before going that way I would make sure there is a clear line on the return fitting on the injection pump and look for any amount of air being processed with the fuel. No fuel flow would indicate the supplied fuel pressure is too low to open the return relief valve. I take it your motor mounts are in reasoable condition as well.

On the 616 engines to me it is important to have 15-19 pounds fuel pressure present in the base of the injection pump. . May be worth checking this after you get the idle smoothed out. As for the dynamic running effect of the differance in low piston speed compression readings you are seeing. I have never totally made my mind up when the compression numbers are in the area you have. Certainly I would not suspect there is enough varience to give extreme shaking at idle. Simular to a cylinder missing. Or anywhere even remotely close to that.. Your quantitive element spraying test is okay but will not address the sequental timing of the injection pump elements. The milli volt method done properly is a better general test to determine what may be going on in my opinion.It will indicate where the problem or problems are.. Closing off the return line is another quick test to see if there is any differance in the idle. No change at all might indicate fuel pressure is really low. Much smoother idle would indicate the pressure in the base of the injection pump should be checked. This is redundant to some extent since all 616 engines should have this checked in my opinion. The milli volt methods use was designed to reduce guessing what is wrong and buying parts on speculation. It takes a little effort to use it properly but it will not mislead if done properly. .You could do a cylinder drop test but it is not sensitive enough to give any real indication in your situation I suspect. That test is where you loosen one injector at a time looking for an abnormal drop compared to the other cylinders.. Much of the above is based on us not being working mechanics. We have to substitute effort for experience. |

|

#9

|

|||

|

|||

|

By "Closing off the return line" do you mean the banjo one that goes from the fuel filter housing (outlet with arrow pointing away) to the injection pump?

How exactly do i block it? Should i remove the banjo and screw and replace it with a shorter screw? I will read about the millivolt method. When i have the engine set to TDC i have the arrow on the crankshaft pointing at 0. When i remove the oil cap, the first cam lobe (cyl 1 exhaust) will be laying flat and pointing to the right while the second (cyl 1 intake) will be pointing straight up. Is that normal? I will also try running the engine with fuel from a bottle to be sure that the screen in the tank isn't clogged. |

|

#10

|

|||

|

|||

|

Quote:

Packman

__________________

83 240D - 4 speed manual - Manilla Beige 189K miles, Tachometer mod, cool wooden shift knob from PeachParts, CocoMats, Original factory paint, manual windows, manual sunroof. Starting to add AudioWrap to this car too!

|

|

#11

|

|||

|

|||

|

Quote:

Read about the methology of checking for chain stretch and cam position in the archives. Basically the cam cannot be more that one sprocket tooth off either way or the valves will hit pistons. Yes it is concievable someone could put on a timing chain one tooth off. You never know what you get into with a really older car. The 616 is a heavy interferance type engine. Verifying the cam timing from the articles in the archives is a good ideal. Your description adds a little doubt into the equation. I thought the lobes should be more equal in position than you describe. They also may be fine when you check properly. If you find the cam off one tooth perhaps the injection pump timing should be evaluated as well. again the info is in the archives and no really special tools are involved. If you find fuel flowing out of the return line during a test then you are in all likelyhood getting enough fuel for testing at idle. If you have adaquate fuel pressure though is partially determined by the close off test. The 616s lift pump or fuel pump if you wish provides less actual pressure than the simular pump on the 617 or five cylinder turbo cars. It has a weaker pressure spring that determines the output fuel pressure of the lift pump. If you like the car later on you can buy a kit to rebuild the pump for about ten dollars. At that time get a surplus spring from the turbo pump and upgrade the fuel pump. There are a lot of good reasons to make that modification in my opinion. Remember that the valves you get to replace the ones in the lift pump are probably changing the original very old ones as well. It is far cheaper to rebuild that pump than deal with a potential roadside breakdown someday. That type of episode lands up costing not only more than ten dollars but usually it has been my experience with almost any type of roadside breakdown a day is lost. Any meaningful fuel restriction would have impacted your ability to drive the car as far more fuel is required then. Yet air in the fuel would have more impact at idle than while under normal operation. Once when transiting one of my 616s home from the states. The driving conditions got so bad I had to stop basically in the middle of nowhere. Letting the engine idle to have heat as I had to sleep in the car. It burnt very little fuel while I snoozed for 6-7 hours. I have heard a quart an hour at idle but never verified it. May even be less. The reason you want everything enginewise working well on a 616. It is one of the few cars you use everything it's got fairly freqently. Last edited by barry12345; 10-24-2012 at 06:25 PM. |

|

#12

|

|||

|

|||

|

It has been some time since I last posted. I finally had some time to check what you guys suggested. I started with timing. I aligned the cam like so

and looked at the balancer markings. When the cam is set to 1st cyl. tdc like in the picture above i have the arrow on the balancer pointing at about 7 deg after tdc. What could this be? Can it just be that the pointer is aligned incorrectly and should be pointing at 0? Is there any other mark on the engine i can check while at tdc? |

|

#13

|

|||

|

|||

|

The marks aren't exactly aligned in the picture. They should be, otherwise the reading will be inaccurate.

Here is an example of aligned marks:  You can remove the glowplugs so that you can turn the engine more easily. If the pointer shows anything other than OT, the chain is stretched. 0–5 degrees after OT is allowable. |

|

#14

|

|||

|

|||

|

Your timing could be slightly retarded from chain wear, but that won't give you a rough idle. I'd be looking at that cylinder with low compression.

__________________

'83 300D, 126K miles. |

|

#15

|

|||

|

|||

|

I will heck the injection pump related stuff and after that concentrate my efforts on that #4 cylinder.

Additionally to having a rough, very shaky idle the engine just doesn't sound the way it should. I had a 240d about 4 years ago and it had that soft mercedes indirect injection sound. This one just sounds like a tractor and i mean literally. I also listened to my friends 300gd with an om617 last week and it sounded just as i remember my previous 240d. Worse case scenario is piston slap on #4 cylinder but i will have a leak-down test done to be sure it's not a valve or the head gasket. The camshaft photo was from another user's post. Mine was spot-on when i tested. |

|

| Bookmarks |

|

|