|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

LinkBack | Thread Tools | Display Modes |

|

#16

|

|||

|

|||

|

Is it possible that those parts in your picture are both from North American models 617turbo and 617 n/a and the euro 617 is different than both of those in your picture? The one on this 617 euro motor looks smaller than the ones in your picture I just looked at the euro and it seems to me that this euro one has a thicker crank balancer and a smaller diameter balancing disc. I wonder if someone tried to use a north American model 617 balancer assembly to fix your Euro 617. I can confirm the North American model 617 N/A in the A.M.... but I am pretty sure that the balancer on that one is different than this euro part. Are you sure that you have a Euro motor?

|

|

#17

|

|||

|

|||

|

Quote:

That vibration damper includes a pulley. According to the FSM the new vibration damper can be installed on old engines, but no mention if the old damper can be installed on new engines. Parts numbers are A6170300103 for the old damper, A6170300803 for the new one. There might also be a A6170300403 for very old vibration dampers (pre 1979) but that part number isn't listed for US models. |

|

#18

|

||||

|

||||

|

The thing I don't understand about Mercedes bureaucracy is that they specify an engine specific part at VIN level rather than the more precise engine number level...

(Oh and well done for looking up the part numbers Govert!)

__________________

1992 W201 190E 1.8 171,000 km - Daily driver 1981 W123 300D ~ 100,000 miles / 160,000 km - project car stripped to the bone 1965 Land Rover Series 2a Station Wagon CIS recovery therapy! 1961 Volvo PV544 Bare metal rat rod-ish thing I'm here to chat about cars and to help others - I'm not here "to always be right" like an internet warrior Don't leave that there - I'll take it to bits! |

|

#19

|

|||

|

|||

|

Quote:

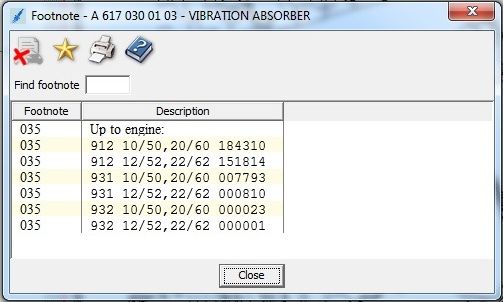

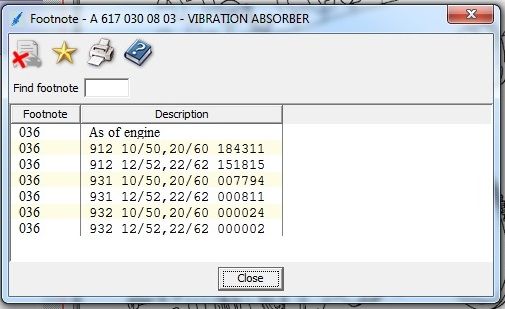

Here are the engine numbers for 0103  And here for the 0803

|

|

#20

|

||||

|

||||

|

^^^great stuff now that is handy!

(I've been saying it for years but I think I am actually going to pay the European subscription for EPC and stop being cheap - Russian EPC is all well and good but it is pretty limited)

__________________

1992 W201 190E 1.8 171,000 km - Daily driver 1981 W123 300D ~ 100,000 miles / 160,000 km - project car stripped to the bone 1965 Land Rover Series 2a Station Wagon CIS recovery therapy! 1961 Volvo PV544 Bare metal rat rod-ish thing I'm here to chat about cars and to help others - I'm not here "to always be right" like an internet warrior Don't leave that there - I'll take it to bits! |

|

#21

|

|||

|

|||

|

Membership of an "official" MB club (more info for clubs in Holland: http://automobiel.mercedes-benz-clubs.com/) comes with free subscription of the EPC, but that could be more expensive than the direct subscription fee for the EPC.

|

|

#22

|

|||

|

|||

|

Thanks Stretch and Govert for the part number info. I actually paid Startekinfo for worldwide EPC info a few years back and had no luck at all accessing the website. Perhaps now that I have a more up to date computer, I'll try again.

Stretch, I appreciate your gentle humor in the link name  ! One of the things I've admired about you while reading your posts is that you combine knowledge with patience and good humor. Sometimes the information cost (time and confusion, what/who to trust) of internet searches just overwhelms me. ! One of the things I've admired about you while reading your posts is that you combine knowledge with patience and good humor. Sometimes the information cost (time and confusion, what/who to trust) of internet searches just overwhelms me.macdoe, the scenario you describe of an oddball part jerry rigged to make do is exactly what has my head spinning. Going to the link Stretch provided for EPC it does seem that the European and US part numbers for non-turbo motors match. I have to go to work for one of my long shifts, so I just had about 10 minutes to scan all these replies. Tonight or tomorrow I'll really get into it and get started on my part search for purchase.

__________________

1983 240D 4spd 1984 300D Euro 4spd non turbo 1982 300D Parts Car (bad auto trans) 1982 240D Parts Car (blown motor) |

|

#23

|

|||

|

|||

|

macdoe, Did you get a chance to compare your two cars? I'm interested but not in a big hurry. Your point about the 79 North American and the 84 euro being different seems to be confirmed by Govert in post 17 and 19 in this thread. I've got to do some more research in The EPC, and find out if the balancing disk that he vibration damper bolts into changed in 1982 also, before I spend my money. Thanks for pointing the difference out, I might have jumped a little early without your and Govert's help.

__________________

1983 240D 4spd 1984 300D Euro 4spd non turbo 1982 300D Parts Car (bad auto trans) 1982 240D Parts Car (blown motor) |

|

#24

|

|||

|

|||

|

Yes, looked at the damper in the 79 and it is different than the 84 euro motor. Hope that helps you out. I am not really familiar with this euro car. It just got delivered on Tues.

Last edited by macdoe; 07-27-2013 at 02:50 PM. |

|

#25

|

|||

|

|||

|

#26

|

|||

|

|||

|

Thank you macdoe and Govert. Based on your observation and information it does seem that my schwingunsdampfer on my 1984 Euro spec 300D was replaced with an earlier model North American market part, just like macdoe guessed (good call, macdoe.)

I am going to check with my friendly MB parts man just for kicks to see how much the correct one costs new. that's if MB's software will let him access and order the part from the US. I suspect that I will probably end up using an earlier (79-82) North American version used part, just like the previous owner did. The original part supplied with the car obviously failed and was replaced. I have to think that perhaps a reason for the failure of the replacement was the use of non MB stainless steel bolts (brittle). I have some time off Monday and Tuesday I'll get a battery in this car and spin the motor a few times to see how the bare balancer looks as far as looseness/wobble as Stretch was legitimately concerned about. I am hoping that I don't need to replace that part also. As well I will have to figure out how to check the torque on the 27 mm bolt holding every thing on the crank. I don't have a torque wrench with that high a value but I know there is a formula to figure torque using a longer (cheater) fulcrum on a torque wrench, I'll have to dig that formula up. Govert, thanks for posting the diagrams from the German manual. Nothing like it in the North American market FSM since non turbo 617 motors were not available here in 1982. Plus now I know that I am dealing with a schwingunsdampfer !

__________________

1983 240D 4spd 1984 300D Euro 4spd non turbo 1982 300D Parts Car (bad auto trans) 1982 240D Parts Car (blown motor) |

|

#27

|

||||

|

||||

|

I think the root of the problem is the knucklehead who used stainless bolts, not you over tensioning the belts. Stainless bolts are only around grade 4 or 5. No wonder they sheared.

__________________

85 300D turbo pristine w 157k when purchased 161K now 83 300 D turbo 297K runs great. SOLD! 83 240D 4 spd manual- parted out then junked |

|

#28

|

||||

|

||||

|

Hi. A few comments:

I had a euro spec 300 NA motor some years back which ran good but had a wobbly HB. When we took it apart the nose of the crank was buggered up. Putting on the HB on these engines is tricky business and often damages the front of the crank and the circular keyways. I would be very suspicious of your crank nose being damaged in this way too, so I recommend a very close examination of it by a machinist if possible. In my case we sourced a US spec crank and used that as a replacement. In the search for the correct crank we had the chance to sit a na block and a turbo block side by side and found a great many differences. IE the nose of the crank on the turbo motor is longer (and perhaps larger diameter too but cannot remember for sure on the diameter). The non turbo motor uses on belt and its wider than the two belts used on the turbo motor so it will always slip if you use the narrower belt. Good luck!

__________________

[SIGPIC] Diesel loving autocrossing grandpa Architect. 08 Dodge 3/4 ton with Cummins & six speed; I have had about 35 benzes. I have a 39 Studebaker Coupe Express pickup in which I have had installed a 617 turbo and a five speed manual.  [SIGPIC] [SIGPIC]..I also have a 427 Cobra replica with an aluminum chassis. |

|

#29

|

||||

|

||||

|

Whilst I encourage you to investigate and check the run out of the bits on the end of the crank I'm not too keen on the idea of re-checking the torque of the 27mm bolt.

I think that so long as the parts on end of the crank are running true I wouldn't mess with that 27mm bolt. To do the job properly you need to have a flywheel clamp => I only managed to torque up my 27mm bolt because the engine just so happened to be out of the car with out the transmission fitted. Has anyone ever made a good DIY tool to lock an OM617 flywheel? In your situation it will be difficult to make sure that the flywheel doesn't spin if you are not using a gucci flywheel lock. To check for the "running true" of the bits on the end of the crank you could do it this way  or this  Obviously these are pictures showing measurements of parts not found on an OM617 but I hope you get the general idea

__________________

1992 W201 190E 1.8 171,000 km - Daily driver 1981 W123 300D ~ 100,000 miles / 160,000 km - project car stripped to the bone 1965 Land Rover Series 2a Station Wagon CIS recovery therapy! 1961 Volvo PV544 Bare metal rat rod-ish thing I'm here to chat about cars and to help others - I'm not here "to always be right" like an internet warrior Don't leave that there - I'll take it to bits! |

|

#30

|

|||

|

|||

|

funola, t walgamuth, Stretch, thanks for the help.

Funola: "I think the root of the problem is the knucklehead who used stainless bolts, not you over tensioning the belts. Stainless bolts are only around grade 4 or 5. No wonder they sheared." I absolutely agree that those stainless bolts were a terrible idea. But based on 1. Non standard bolts 2. Junkyard marks on the schwingunsdampfer 3. Macdoe’s visual comparison of his cars 4. Govert’s images from the German FSM, this is the second failure (at least! It’s a 300,000 mile car.) See t walgamuth: " The non turbo motor uses on belt and its wider than the two belts used on the turbo motor so it will always slip if you use the narrower belt." Yes t walgamuth, I was using the wider belt 13 x 1030mm. But I’ve been using cheap belts, O’Reilly’s, Autozone, Advance. I’ve ordered some Contitech belts and am hoping they are a better fit. The one 123 I have owned that was dealer serviced with the receipts to back it up is my 1982 300D (Us spec, now a parts car) That car is a turbo and had the double alternator/water pump belts. I pulled the alternator out of that car and cut the belts when I did (they were at least 10 years old when I cut them) but I wish I kept them just for reference. The Mercedes star belts were not notched, and they seemed thicker in depth, fit very well in the pulley groove all the way to the bottom. Do you have any experience with the Continental/Contitech belts? Or do you think I’d be better off ordering through a Mercedes dealer? My understanding is that Continental was the OEM supplier, but the way parts businesses have changed, that’s no guarantee that they still manufacture/sell the same design or quality part. "Putting on the HB on these engines is tricky business and often damages the front of the crank and the circular keyways. I would be very suspicious of your crank nose being damaged in this way too, so I recommend a very close examination of it by a machinist if possible." Yes, this is my fear. I think that Stretch’s method of checking for “running true” is something I could do myself. My funds are limited and I originally bought this car to eventually use the flywheel, driveshaft, and differential inorder to swap my 617 turbo motor into my 1982 blown motor 240D. Driving the 1984 300D Euro spec around I was really impressed by how drivable and smooth the combination of the non turbo 617 motor and manual trans is. If this motor is still in good shape, I’m inclined to swap it instead. Less to go wrong, and plenty of power for me, both in passing/merging and top speed. On the other hand, if the crank/balancing disk is fried, I guess it would be time to go ahead with the swap I originally had in mind: turbo 617 in front of a 4 speed manual trans. Stretch: "I wouldn't mess with that 27mm bolt. To do the job properly you need to have a flywheel clamp" Yes you are right, I wasn’t thinking about locking the flywheel, even with the car in gear, I’d probably get the entire car rolling. Though I might try it in reverse and backed up against a wall or a curb  then I might only spin the tires on the pavement then I might only spin the tires on the pavement Just kidding, the dial indicator test seems like an adequate test. I need to see if I can borrow one and check to see if there is enough continuous flat surface on the balancing disk to contact. If not I could always mount the schwingundampfer and read off of that, right? I think that might be an easier setup. Regarding your thread on the flywheel lock, did you ever check out this thread? Weird main pulley failure. HELP.... post 6 " The only trick to getting the balancer off is loosening the big bolt. The balancer should have a couple of cutouts. One option (per FSM) is to jam the balancer with a chisel or 1/2" extension bar through one of the cutouts. Use a wrench with a long handle, 24" at least. Once the bolt is out, just pull the balancer off with a generic balancer puller. Autozone will lend you one for free.""" Post 32 "I was able to draw the balancer all the way on without the crankshaft turning. When it was time to apply the final torque of 270-330 Nm, I jammed the balancer by placing a 1/2" extension bar through one of the balancer slots and underneath the upper oil pan lip. This is exactly what is illustrated in the engine service manual for my year model ('82.) (Yes, the manual actually shows a picture of a 1/2" extension bar through the balancer.) For earlier models with the 722.120 transmission, the service manual calls for the use of a tool which appears to lock the flywheel. Maybe those vehicles have a different balancer without the cutouts. My balancer had a rounded notch into which the extension bar fit nicely." I have been unable to find this method in my “Service Manual Engines 615, 616, 617.91” Mercedes-Benz of North America, Inc. 1991, book, that doesn’t mean it’s not in there. Also it may be in an earlier edition of the service manual and not in a later one. And not everything in the FSM is accurate or complete. In the section 03-340 Removal and installation of pulley, vibration damper, and balance plate, right at the beginning of the section it specifies an M8 x65mm bolt(s) which best I can tell are NEVER used to mount pulleys on the 615/6/7 series motors. Worse, I followed the torque values listed for that bolt which I later found was about 45% higher than Mercedes generally calls for for a bolt of the correct size (M8x45) on my car. I think I mentioned above that I’m pretty sure that when I reinstalled the beat up schwingunsdampfer for a few days, I snapped a bolt while torquing down. The parts diagrams and lists do show the correct bolt for my car (M8x45) but none of them show the correct bolt for a turbo 617 (M8x30), nor is there a diagram for the pulley/damper/disc setup for a 617 turbo. So I would not immediately assume that it is “no longer recommended” just because it no longer appears.

__________________

1983 240D 4spd 1984 300D Euro 4spd non turbo 1982 300D Parts Car (bad auto trans) 1982 240D Parts Car (blown motor) Last edited by pfbenz; 07-29-2013 at 05:55 PM. Reason: clarity |

|

| Bookmarks |

| Thread Tools | |

| Display Modes | |

|

|