|

|

|

|

|

|

|

|

|

|

|

#1

|

|||

|

|||

|

1985 300D W123 Subframe Bushings Meyle

Changed my subframe bushings today. Used Meyle bushings that I got for 65 with free shipping. Was rather cautious based on the postings regarding the aftermarket bushings vs the OEM, but decided to risk it.

Had no real issue removing the old bushings. Used a cold chisel to get them started out, then a little prying and rocking and they came right out. I then tried to use some dish soap and a hydraulic jack to set the left bushing. No way! Got it to within 1/2 inch and no more. Next day, got a piece of 1/2 inch 13 tpi all thread as suggested here on the forum. Cut it to 8". Instead of the welded up u bracket that I've seen fabricated, I found that I had a huge socket in the tool box. I believe it might have been for a 4x4 hub on my 97 F250. At any rate it's diameter fits fairly well to the diameter of the steel part of the bushing on the 300D. Used the all thread and some big washers on top and she slid right together. After finishing the left side I proceeded to the right and had it signed, sealed and delivered in less than 30 minutes. Oh and don't forget the Sil Glyde. This stuff is magic lube. Guy at adv auto tried to convince me that it was only for brakes and I needed some wd40 silicone. Told him this is what the guys on the forum use and that's what I bought. Worked Fantastic. I'm attaching a couple of pics of my setup. I know this post is pretty much duplicated, but I appreciate the info i've learned on this site; had to try to return the favor. |

|

#2

|

||||

|

||||

|

Please

measure the socket diameter.

thanks .

__________________

ASE Master Mechanic asemastermechanic@juno.com Prototype R&D/testing: Thermal & Aerodynamic System Engineering (TASE) Senior vehicle instrumentation technician. Noise Vibration and Harshness (NVH). Dynamometer. Heat exchanger durability. HV-A/C Climate Control. Vehicle build. Fleet Durability Technical Quality Auditor. Automotive Technical Writer 1985 300SD 1983 300D 1984 190D 2003 Volvo V70 2002 Honda Civic https://www.boldegoist.com/ |

|

#3

|

|||

|

|||

|

X2 on Syl-Glyde.

When I did our 85 300D, I read to use KY Jelly, the bushing went in to about 1/2 inch. Left it over night with pressure, and the next morning it was the same. Removed it, cleaned up the mess and used Syl-Glyde, and she went right in. Great stuff. Thanks for the feed back, and welcome to the Forum.  Charlie

__________________

there were three HP ratings on the OM616... 1) Not much power 2) Even less power 3) Not nearly enough power!! 240D w/auto Anyone that thinks a 240D is slow drives too fast. 80 240D Naturally Exasperated, 4-Spd 388k DD 150mph spedo 3:58 Diff We are advised to NOT judge ALL Muslims by the actions of a few lunatics, but we are encouraged to judge ALL gun owners by the actions of a few lunatics. Funny how that works |

|

#4

|

|||

|

|||

|

Also would like to know the socket size....seems like a great easy cheap press...

__________________

|

|

#5

|

|||

|

|||

|

3/4" Drive 2.75" Socket.

|

|

#6

|

|||

|

|||

|

Where do I find subframe bushings on peachparts? All I can find is the rear conrol arm bushings.

__________________

1985 300 TD 448K 1984 300 TD 278K 1983 240D euro 240k 1994 f-250 idi turbo 330K 1986 f-350 IDI 1987 F-350 IDI 1985 JD 1050 4wd 1965 IH 3660 |

|

#7

|

||||

|

||||

|

FYI

Quote:

1985 300 TD 301K 1984 300 SD unknown mileage 1972 220 D project .

__________________

ASE Master Mechanic asemastermechanic@juno.com Prototype R&D/testing: Thermal & Aerodynamic System Engineering (TASE) Senior vehicle instrumentation technician. Noise Vibration and Harshness (NVH). Dynamometer. Heat exchanger durability. HV-A/C Climate Control. Vehicle build. Fleet Durability Technical Quality Auditor. Automotive Technical Writer 1985 300SD 1983 300D 1984 190D 2003 Volvo V70 2002 Honda Civic https://www.boldegoist.com/ Last edited by whunter; 11-11-2013 at 10:03 PM. |

|

#8

|

|||

|

|||

|

Awesome thanks, I will put one on my shopping list when I do mine.....

__________________

|

|

#9

|

|||

|

|||

|

For the life of me, i can't remember what I bought it for, but it works.

On another note, Changed the left lower and upper ball joints today. I think the hardest part was getting the steering knuckle off. Used a $25 tool from AA; like to think it was surely going to strip, but it finally popped it off. From there, I beat the old one out and then used a large diameter socket out of a ball joint kit that was worthless for pressing these in. One of the sockets was the right diameter to match the Ball Joint lip. Used a cold chisel and just worked it around the perimeter until it seated. I think I might be ready to put my new ride on the road to work this week. |

|

#10

|

|||

|

|||

|

Sorry, the 85. We are on a 123 thread so I didn't think about my sig. The 85 is now at 360 and the others are long gone.....guess I should update.

__________________

1985 300 TD 448K 1984 300 TD 278K 1983 240D euro 240k 1994 f-250 idi turbo 330K 1986 f-350 IDI 1987 F-350 IDI 1985 JD 1050 4wd 1965 IH 3660 |

|

#11

|

||||

|

||||

|

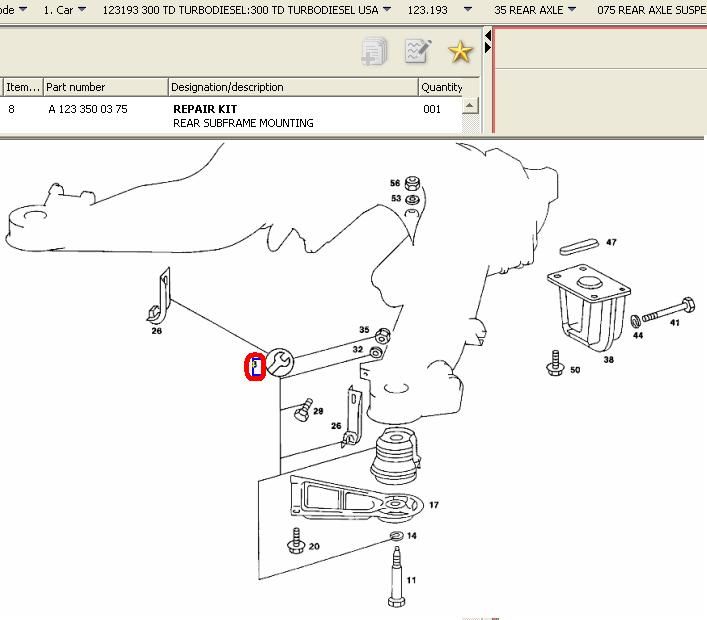

Answer

1985 300 TD rear subframe mounts.

Repair kit MB# 1233500375 .

__________________

ASE Master Mechanic asemastermechanic@juno.com Prototype R&D/testing: Thermal & Aerodynamic System Engineering (TASE) Senior vehicle instrumentation technician. Noise Vibration and Harshness (NVH). Dynamometer. Heat exchanger durability. HV-A/C Climate Control. Vehicle build. Fleet Durability Technical Quality Auditor. Automotive Technical Writer 1985 300SD 1983 300D 1984 190D 2003 Volvo V70 2002 Honda Civic https://www.boldegoist.com/ |

|

#12

|

|||

|

|||

|

That kit doesn't appear to have the rubber mount. That is the only part I need. The actual subframe bushings look ok, but the rubber part being installed in the op is what I am looking for.

__________________

1985 300 TD 448K 1984 300 TD 278K 1983 240D euro 240k 1994 f-250 idi turbo 330K 1986 f-350 IDI 1987 F-350 IDI 1985 JD 1050 4wd 1965 IH 3660 |

|

#13

|

||||

|

||||

|

I am looking at doing same job one of these days. I was thinking of using a cheap 2.75" hole saw instead of the socket (with teeth ground off). Is that the best size or would a larger one be better? Maybe an even larger one could be used for removal too?

Regarding the kit, this is what I get when looking for the kit on another site. Seems to have all the parts including the bushing. Seems as though PP site picture is wrong. From the price, it must include the whole kit!

__________________

Graham 85 300D Last edited by Graham; 11-14-2013 at 02:14 PM. |

|

#14

|

||||

|

||||

|

Answer

Quote:

Repair kit MB# 1233500375  Repair kit MB# 1233500375 .

__________________

ASE Master Mechanic asemastermechanic@juno.com Prototype R&D/testing: Thermal & Aerodynamic System Engineering (TASE) Senior vehicle instrumentation technician. Noise Vibration and Harshness (NVH). Dynamometer. Heat exchanger durability. HV-A/C Climate Control. Vehicle build. Fleet Durability Technical Quality Auditor. Automotive Technical Writer 1985 300SD 1983 300D 1984 190D 2003 Volvo V70 2002 Honda Civic https://www.boldegoist.com/ |

|

#15

|

|||

|

|||

|

Quote:

|

|

| Bookmarks |

|

|