|

|

|

|

|

|

|

|

|

|

|

#16

|

||||

|

||||

|

Wear issues or not Manuals are pretty clear that you turn the Engine in the Direction of Rotation towards top dead center and when the Dial Indicator Stops Moving that is Top Dead Center.

They do not account for any averaging of the number of degrees that the Piston Remains motionless during Engine Rotation before it starts going back down. Also you are setting the Crankshaft to (the begin of Top dead Center; My words) the Pistons highest part of the Piston Stroke and that has nothing to do with any Valve Train Wear. So anything instructions beyond what the Mercedes Service Manual has is experimental.

__________________

84 300D, 82 Volvo 244Gl Diesel |

|

#17

|

|||

|

|||

|

Thanks everyone for the help, have been mulling this over for a few days. Pulling the prechamber does not appeal to me now that I think about it. The straw and oil suggestion has me interested.

This afternoon I reset the cam to crankshaft relationship (had tried slipping a single tooth in each direction, but it did not help my problem). Now I'm back to where I started, an engine that won't start, it tries, but just can't catch its breath and get going. Dunno, maybe I'm looking in the wrong direction. Am running out of ideas and steam. |

|

#18

|

|||

|

|||

|

ok.. lets take a step back here. Let us know what YOU think you do not know. It's hard to understand things you don't know much about. Try to find the places where you think you are making mistakes or things just don't seem right. You will not be thought an idiot, if someone says something, we'll kick their fkn arse. Most of us are here because this is fun for us and we like talking about it. any question is invited. Just tell us whats not right and we'll explain it to the best of our limited abilities. If you need a picture of whats going on in the engine, just say so.. i got lots and can draw Picasso's in MS paint if you like. Back to the problem: There 2 ways to install a camshaft on these cars; both of them require the crankshaft to be at top dead center (tdc) and the chain on the vacuum pump side to have zero slack. 1) this is the correct way; it is in time with the injection pump. Fuel will be delivered to the piston when the valves are closed and remain closed as the piston goes down. 2) this is the 'not so great' way; it is out of time with the injection pump and fuel will be delivered when the valves are closed but the intake valve opens as the piston goes down. So, you've a got a 50% chance of getting it right and you've tried twice. You'll get there. there is another way to tell if the IP (pump) is timed to the camshaft. . . or what stroke the engine is on. Let me know if you want to go further with this. I'm running out of beer right now. |

|

#19

|

|||

|

|||

|

Thanks jt20 for the encouragement. To bring it all together, here is a list of what I’ve done and what the current symptom is;

1) Replaced #14 head with #22 head. Set the crank indicator to #1 TDC before I started, didn't move the crank at all during the head replacement process. Turned out to only have a bad head gasket (oil in the coolant), but installed the new head anyway using the cam that came with the head). 2) Had the valve stem seals replaced at the machine shop while it was being pressure tested. 3) New parts; lifters, glow plugs, vacuum pump, water pump, radiator, rebuilt and tested injectors, correct (used) injector lines, thermostat, gaskets (head and others), new secondary fuel filter (primed with clean new diesel), vacuum shutoff valve (installed correctly pre install guide I found on this forum). 4) I removed the crank indicator to clean it (was very grimy) - and did my best to get it back in correct position, but there is slop there for adjustment. 5) When I was installing the upper timing chain guide rail the IP sucked away all my slack (I wrote about this in another post) - I incorrectly rotated the engine one turn to get the slack back, then put the cam back in place. This put the cam 180 out of time, engine would not start at all. Removed cam sprocket and rotated 180 again, now all is in time (I think) but still no start (but it tries now to catch). Engine was set to TDC before I removed cam sprocket and rotated engine by hand again). 6) Noticed that I am not getting fuel out of the first two IP pistons. Checked the IP hard lines and they all are clear (they pass compressed air just fine). I have been told by a very trusted friend that this engine will run on 4 cylinders, roughly, but it will run. 7) On advice from some friends, I tried slipping one tooth on the cam in each direction (with a manual rotation or two of the engine to be sure there was no interference). Nothing, still no start). Now it is all back at 0. 8) Checked the IP timing mark - it shows up at about 15 degrees ATDC - which is where I would expect it to be (right)? 9) Previous owner installed an accessory electric fuel pump (he ran WVO all the time - yuck) - but I couldn't hear it running, so I removed it yesterday and changed out the plastic fuel filter. Took some fiddling - but I finally got it to refill with fuel. Still no start. 10) When reassembling the engine I removed the ALDA completely and plugged the ALDA vacuum line (I have read in many places on this forum that this is ok to do). 11) I tried unplugging the vacuum shutoff valve line to see if there was a fault in that system, still same result. Engine won’t start. 12) I notice that before I try to start the car, the emergency stop lever is in the UP position, but after a long attempt of starting, the lever is in the DOWN position. After about 20 seconds of sitting it returns to the UP position. When aligning the cam, I am using the single hash mark located on the metal collar right behind the cam sprocket. I line it up with the cam tower marks. My cam is marked “07”. So is the cam that came on my #14 head. I have a second #22 head (that is cracked) – but it’s cam has no number on the collar and also has what looks like several hash marks (dunno what that’s all about. This cam also has the star type bolt, not a hex bolt). I’ll have to look at the FSM, there is something in there about the meanings of the collar numbers. Before I pulled the head, this car ran like a kitten purring. I hated to do the job at all, but there was a lot of oil in the coolant - so it had to be done. I added 5 gallons of new diesel to the tank right before I began trying to start this car. During the cranking process I am getting black smoke out of the tail pipe that smells like diesel. I’m also getting some similar smoke in the engine compartment (probably from the turbo – I have the intake elbow off to I can plug the air supply in case the engine tries to run away). The engine cranks at good speed. It sputters and tries to get going, but it just never does. Very frustrating. All of what I’ve written here has been done since August of 2013. I will try this weekend to make a video of what the engine sounds like and figure out how to post it on YouTube and link it here. Maybe that’ll help. |

|

#20

|

|||

|

|||

|

Sounds like you are right on point. Excellent, thanks.

TDC is not your problem, its way obvious when the chain is a tooth off - you've seen that for yourself. Timing chain ...etc: From now on I am going to assume you can currently verify that with the crank @ 0 the mark on the cam sprocket aligns to cam holder #1. And that the timing is correct. Check those one more time now that everything has been spun around, then fiddle with the crank timing indicator (keep the crank in place) just to get an idea of how much error there is on that thing. And "IP timing mark" means that tab of metal behind a bolt cover on the bottom of the IP, correct? Some questions: Have you done fuel system work on this car before? Removed injection lines, bled the fuel supply system, replaced injectors or replaced fuel filter before? Are you familiar with how much cranking it takes to get the injection lines filled back up with fuel? Keep the fuel pedal down when cranking to fill up quicker. Are the injection line nuts loose when you are cranking? Did you tighten them up before cranking? Check all your fuel system lines and make sure they are oriented correctly and have washers on each side of the banjo fitting. I agree with you that the shut off vacuum line should be left off for now - just a precaution. I think you're almost there. |

|

#21

|

||||

|

||||

|

When you say crank indicator what do you mean? You should absolutely pull a prechamber at this point IMO.

__________________

http://superturbodiesel.com/images/sig.04.10.jpg 1995 E420 Schwarz 1995 E300 Weiss #1987 300D Sturmmachine #1991 300D Nearly Perfect #1994 E320 Cabriolet #1995 E320 Touring #1985 300D Sedan OBK #42 |

|

#22

|

||||

|

||||

|

You might revisit the shutoff actuator with it bobbing the way you say it does. It should jump up when you turn the key to glow and stay there until you turn the key to off. With a tight vacuum system, it should say down for days if not weeks. Fabricate a hook to hold it vertical while you're cranking. Mind that you have to unhook it to shut off the engine.

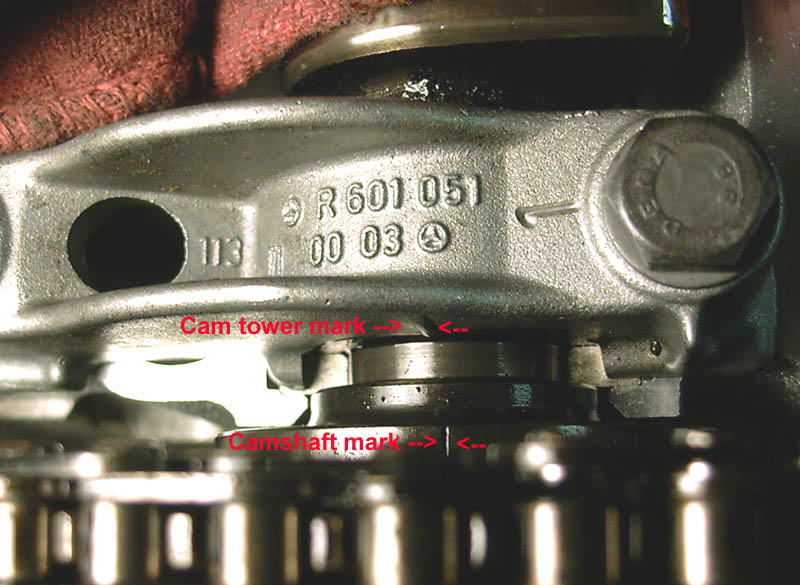

In case you haven't seen them, these are the cam timing marks -  Sixto 87 300D |

|

#23

|

|||

|

|||

|

That is an excellent question.

Can you tell us what you are lining the crank Zero (OT) up with. - just to clear that up. |

|

#24

|

|||

|

|||

|

I will take a photo of it tomorrow, there is a finger that points at the markings on the flywheel. It is held in place with a single Allen head bolt. On the left hand side (the passenger side if you are standing in front of the car facing the engine) there is a short threaded rod that I do not know what it is for, it. Got in the way of the water pump pully when I installed it (now I remember that I had to move this guide a little when I was putting everything back together).

|

|

#25

|

||||

|

||||

|

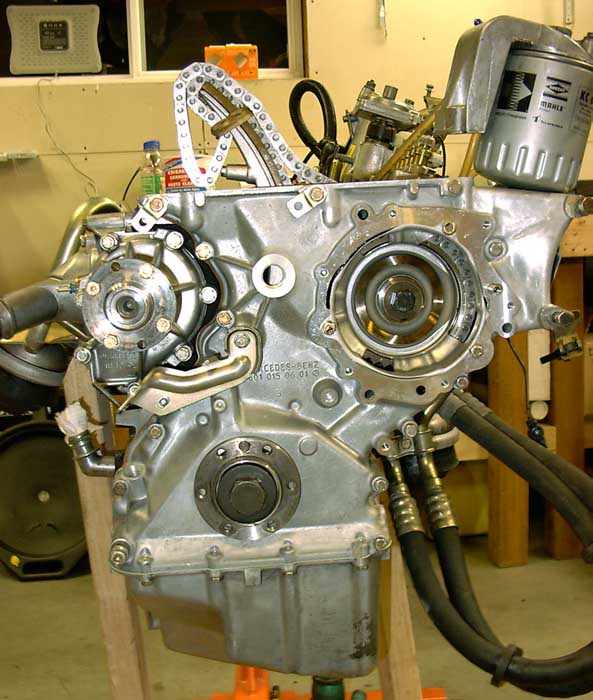

Like you can get a camera in there

Here's a picture for discussion purposes - Here's a picture for discussion purposes - Here's one with the damper in place -  Sixto 87 300D |

|

#26

|

|||

|

|||

|

Thanks Sixto, it's the brass colored part, directly above the crank. It is about 4 inches long, in your photo you can see the thread screw pointing north on the left hand end. I don't have a way to add arrows to a photo currently but hopefully my description narrows it down.

|

|

#27

|

|||

|

|||

|

Use the numbers on the disk behind the pulley. Should read: OT

Don't use that dowel as the zero indicator. You already said you checked the pump @ 15ATDC, so I assume you are not using the dowel. |

|

#28

|

|||

|

|||

|

H a l l e l u I a h !

IT RUNS, IT RUNS, IT RRRUUUNNNNSSSSS !!!!!! Klause first START! - YouTube It turned out to be, wait for it, wait for it.......a SINGLE washer on the secondary fuel filter banjo connection (the one all the way to the left). 6 stinking weeks of fussing with this and it was something stupid that I forgot! Wow - I have learned so much doing this head replacement myself. Probably the biggest lessons are; be humble, be tenacious and always be polite. Now I have to sort out a few other new problems, but I first want to bask in joy and happiness for a while. Thank you, thank you, thank you to everyone who has gotten me this far.

|

|

#29

|

|||

|

|||

|

Next time I'm in VA I'll buy you a pint... or 3.

congrats. |

|

| Bookmarks |

| Thread Tools | |

| Display Modes | |

|

|