|

|

|

|

|

|

|

|

|

|

|

#1

|

|||

|

|||

|

compression test 1987 300sdl

I have a 87 sdl with over 250000 miles on her. The problem is when I start the engine cold it rocks and rolls and then smooths out once it warms up. Also blows grey smoke til it warms up. I did a compression test and the reading were as follows 1,3,5 and 6 were showing 300 psi and number 2 was showing 400 psi this was with engine warm and all injectors out. my question is where do I go from here ?

|

|

#2

|

||||

|

||||

|

Answer

Remove the cylinder head.

This leads me to suspect a bad head or gasket. .

__________________

ASE Master Mechanic asemastermechanic@juno.com Prototype R&D/testing: Thermal & Aerodynamic System Engineering (TASE) Senior vehicle instrumentation technician. Noise Vibration and Harshness (NVH). Dynamometer. Heat exchanger durability. HV-A/C Climate Control. Vehicle build. Fleet Durability Technical Quality Auditor. Automotive Technical Writer 1985 300SD 1983 300D 1984 190D 2003 Volvo V70 2002 Honda Civic https://www.boldegoist.com/ |

|

#3

|

|||

|

|||

|

Quote:

Then a leak down test, doing that would hopefully identify more accurately exactly where the combustion chamber pressure is leaking off to. Could be past the piston rings, could be past valve seats, could be past valve guides and seals. Observing where pressure is leaking will help identify what is not working as designed. With each cylinder near its TDC the space is pressurized and then the speed at which that pressure bleeds of is observed and noted. The faster pressure bleed rates should correspond to lower compression readings. Depending on how fast the pressure bleeds you might be able to confirm the pressure loss fault by listening at the exhaust manifold for exhaust valve seat issues, the intake manifold for intake valve seat issues, under the valve cover for valve guide/seal issues and at the dip stick for piston ring issues. You listen for air escaping, some type of amplified listening apparatus is helpful. That being said, your symptoms are very typical of these engines particularly ones that don't have glow plugs that are reasonably new. The alloy heads are a huge heat sink and they take a bit longer to warm up. You might find it valuable to do a search of the archives for "purple wire" or "purple wire fix" it is a simple mod that allows the glow plugs to stay energized for the longest period possible and helps with the symptoms you've described. Your compression test readings might benefit from a second do over paying particular attention to making everything connect securely and leak proof as well as verifying the accuracy and repeatability of the gauge itself, unless you are certain the tool is worth complete confidence in its readings. A cheap HF tool can often give erroneous results. Yanking the cylinder head off might eventually be required but it probably isn't the logical next step unless you prepared to embark on a full cylinder head R&R to address what is really from your description little more than an annoyance thus far. Even a DIY head gasket replacement alone is a couple hundreds of dollars most likely, paying someone else will easily triple or more that. Last edited by Obamalamadingdong; 02-13-2014 at 03:57 PM. |

|

#4

|

||||

|

||||

|

I disagree

Quote:

With the known OM603 gasket and cylinder head issues, we can only hope it is only a failed gasket. 3.5 bent rod? 3.5 bent rod? - PeachParts Mercedes ShopForum 3.5 Liter "Rod Bender" 3.5 Liter "Rod Bender" The #14 head on the 603, really bad? For sure? The #14 head on the 603, really bad? For sure? - PeachParts Mercedes ShopForum 603.96 Engine Head Crack Survey 603.96 Engine Head Crack Survey - PeachParts Mercedes ShopForum my turn for the OM603 cracked head syndrome my turn for the OM603 cracked head syndrome - PeachParts Mercedes ShopForum Is a 603 engine supposed to knock? Is a 603 engine supposed to knock? - PeachParts Mercedes ShopForum 350SDL Engine Problems 350SDL Engine Problems - PeachParts Mercedes ShopForum GASP! NO! (insert explicative here!) 603 help GASP! NO! (insert explicative here!) 603 help - PeachParts Mercedes ShopForum oil pump chain broke on 86 300sdl ???? how to replace it ??? oil pump chain broke on 86 300sdl ???? how to replace it ??? Timing chain stretch and replacement? Timing chain stretch and replacement? - PeachParts Mercedes ShopForum Specialized Indicator for IP Timing Specialized Indicator for IP Timing - PeachParts Mercedes ShopForum 3.5l Injection pump 3.5l Injection pump - PeachParts Mercedes ShopForum 603 Injection Timing 603 Injection Timing - PeachParts Mercedes ShopForum 603 IP timng lock tool 603 IP timng lock tool - PeachParts Mercedes ShopForum .

__________________

ASE Master Mechanic asemastermechanic@juno.com Prototype R&D/testing: Thermal & Aerodynamic System Engineering (TASE) Senior vehicle instrumentation technician. Noise Vibration and Harshness (NVH). Dynamometer. Heat exchanger durability. HV-A/C Climate Control. Vehicle build. Fleet Durability Technical Quality Auditor. Automotive Technical Writer 1985 300SD 1983 300D 1984 190D 2003 Volvo V70 2002 Honda Civic https://www.boldegoist.com/ |

|

#5

|

|||

|

|||

|

What was the pressure on #4?

__________________

'83 300D, 126K miles. |

|

#6

|

||||

|

||||

|

And I thought I was insidious

I was wondering about all injectors open, does this mean glow plugs still in I hope? I was wondering about all injectors open, does this mean glow plugs still in I hope?

|

|

#7

|

||||

|

||||

|

Quote:

|

|

#8

|

|||

|

|||

|

Quote:

There would be ZERO compression if the glow plugs were not installed while testing using a nozzle holder type adapter. The only reason to have the nozzle holders out would be if that type of adapter was being used. Therefore the fact that any compression reading was obtained would lead one to believe the glow plugs remained installed during the test. |

|

#9

|

||||

|

||||

|

Quote:

|

|

#10

|

|||

|

|||

|

compression

that is correct glow plugs were left in, forgot 4 was also at 300 psi only 2 was off at 400. I did use a HF gauge so I feel preasure are close. I read at alldata do not do a wet test as this engine may start on you and the compression will go through the roof enough to blow the gauge. don't know if this is true or not but didn't try it just the same. The tester is screwed into each cylinder nozzle hole

|

|

#11

|

||||

|

||||

|

What is the normal spec to compare with?

|

|

#12

|

|||

|

|||

|

Measured with engine at temperature.

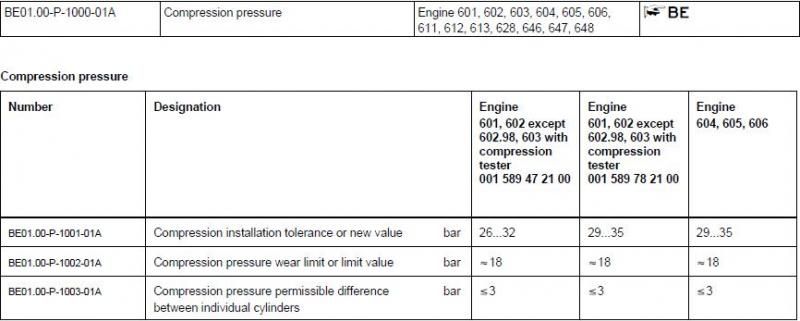

Service manual specs: ===================== Normal pressure: 26-32 bar 377-464 pis Minimum pressure: approx. 18 bar 261 psi Permissible difference between cylinders: 3 bar 43 psi

__________________

Not MBZ nor A/C trained professional but a die-hard DIY and green engineer. Use the info at your own peril. Picked up 2 Infractions because of disagreements. NOW reversed.  W124 Keyless remote, PM for details. http://www.peachparts.com/shopforum/mercedes-used-parts-sale-wanted/334620-fs-w124-chasis-keyless-remote-%2450-shipped.html 1 X 2006 CDI 1 x 87 300SDL 1 x 87 300D 1 x 87 300TDT wagon 1 x 83 300D 1 x 84 190D ( 5 sp ) - All R134 converted + keyless entry. |

|

#13

|

||||

|

||||

|

Good stuff! Thank you.

|

|

#14

|

||||

|

||||

|

More data on topic

.

__________________

ASE Master Mechanic asemastermechanic@juno.com Prototype R&D/testing: Thermal & Aerodynamic System Engineering (TASE) Senior vehicle instrumentation technician. Noise Vibration and Harshness (NVH). Dynamometer. Heat exchanger durability. HV-A/C Climate Control. Vehicle build. Fleet Durability Technical Quality Auditor. Automotive Technical Writer 1985 300SD 1983 300D 1984 190D 2003 Volvo V70 2002 Honda Civic https://www.boldegoist.com/ |

|

#15

|

|||

|

|||

|

Quote:

If you put the oil in the cylinder and crank the engine over to disperse the oil in the cylinder before you install the compression tester you will likely eliminate the chance of hydraulic lock. That would be the other risk of a wet test. Hydraulic lock bends rods and such, it is not good. Read the manual, do what it says. |

|

| Bookmarks |

|

|