|

|

|

|

|

|

|

|

|

|

|

#16

|

||||

|

||||

|

Quote:

__________________

85 300D turbo pristine w 157k when purchased 161K now 83 300 D turbo 297K runs great. SOLD! 83 240D 4 spd manual- parted out then junked |

|

#17

|

|||

|

|||

|

Good call. I will try that.

No I have been driving the car every day this week and by the time it has cooled down enough to work on, I havent wanted to go work on it. Tomorrow I am getting a new windshield, and either later tomorrw or friday I will do some more diagnostics and swap to the core that I triee to get any rust or calcium out of.

__________________

'85 300D - federal spec, built in late 84. 85 300D Complete AC System Rebuild |

|

#18

|

||||

|

||||

|

Have you checked the monovalve control voltage characteristic? Here's a video https://www.youtube.com/watch?v=74fyla3aG6U of what it should look like. I have an LED connected across the monovalve coil, out the hood in front of windshield.

LED on = monovalve plunger extended= no coolant flow. sequence: 1. temp dial @ max cool (detent)= LED constant on = no coolant flow through heater core. 2.temp dial @ max hot (detent) = LED constant off = full coolant flow through heater core 3. temp dial @ 26 C = LED cycling on/off= partial coolant flow through heater core. note the longer on time than off time 4. temp dial @ 20C = LED cycling on/off. note the longer on time compared to 26C = less coolant flow through heater core 5. temp dial @ 18C= LED cycling on off. LED on time is much longer and appears to be constant on. If I let the camera run, which I didn't in order to make the video shorter and less boring, you'd see an off blip at around a minute or 2 further (to let a little coolant through the heater core)

__________________

85 300D turbo pristine w 157k when purchased 161K now 83 300 D turbo 297K runs great. SOLD! 83 240D 4 spd manual- parted out then junked Last edited by funola; 11-12-2016 at 11:48 AM. |

|

#19

|

|||

|

|||

|

Not yet. That will be part of my diagnostics when I get time to work on it. Right now I am waiting on my new windshield- which is a muuuuch needed improvement

__________________

'85 300D - federal spec, built in late 84. 85 300D Complete AC System Rebuild |

|

#20

|

|||

|

|||

|

So they found a small rust hole under my weatherstripping. Will need to be patched before they can install the glass. Car is stuck at the glass place for now.

__________________

'85 300D - federal spec, built in late 84. 85 300D Complete AC System Rebuild |

|

#21

|

|||

|

|||

|

I haven't had much time to work on the car this week, and it's not drivable until I get the windshield frame patched and the glass reinstalled.

Last night I did get an hour or so to mess with the monovalve with the help of a friend. The first thing was to pull the unit out of the car again. I had installed the spacer in the wrong spot - which means that the solenoid wasn't able to extend as far before sealing. I'm 90% sure this was the problem. When I did some earlier testing using a food scale and trying to measure activation force I realized that the extension force varies substantially over the range of extension (which makes sense, as the steel core is moving within the magnetic field). I suspect that it was not extending with enough force to hold back water pressure at high temp, so it was getting forced shut. The second thing was to remove all of the rubber parts from the core, then heat it up to see if it started to bind. We got it to well above boiling, and were still able to actuate both cores smoothly. We could have used boiling water, but it was easier to use a heatgun. Next, we reassembled the unit - this time using the core that had been soaked in rust release agents as well as some vinegar. We made sure to have the spacers in the correct spot, then installed it in the car. Finally, we rigged up some wires and a light bulb to test the electronic control logic. I had similar results as your video and tests, so I'm pretty confident that electronically speaking the system is working as intended. I wasn't able to run the car long enough to get it up to full temperature, since it's not drivable. Hopefully I'll get the car into the bodyshop soon, then the glass reinstalled, for final testing. I didn't have time last night to get into trying to test spring strength, but both myself and my friend agreed that the Bosch unit is noticeably stronger than the MTC unit in that regard. I will need to find another MTC unit at some point, as I destroyed the screen on my good diaphragm unit removing it. I don't think that screen will dramatically impact the functionality of the part.

__________________

'85 300D - federal spec, built in late 84. 85 300D Complete AC System Rebuild |

|

#22

|

|||

|

|||

Somehow it just clicked that the difference between the car at lower temperatures and full temperature is that the thermostat should be opening near full temperature. I'd bet that's what's changing the pressure against the monovalve and forcing it open.

__________________

'85 300D - federal spec, built in late 84. 85 300D Complete AC System Rebuild |

|

#23

|

||||

|

||||

|

Quote:

Where did you install the spacer or did you leave it out?

__________________

85 300D turbo pristine w 157k when purchased 161K now 83 300 D turbo 297K runs great. SOLD! 83 240D 4 spd manual- parted out then junked |

|

#24

|

|||

|

|||

|

I had it behind the plunger assembly for some stupid reason. Now I have it between the plunger and the snap ring, like in your picture. That means I gained the thickness of the spacer in opening stroke before the plunger makes contact with the plastic housing and forms a seal.

__________________

'85 300D - federal spec, built in late 84. 85 300D Complete AC System Rebuild |

|

#25

|

||||

|

||||

|

Quote:

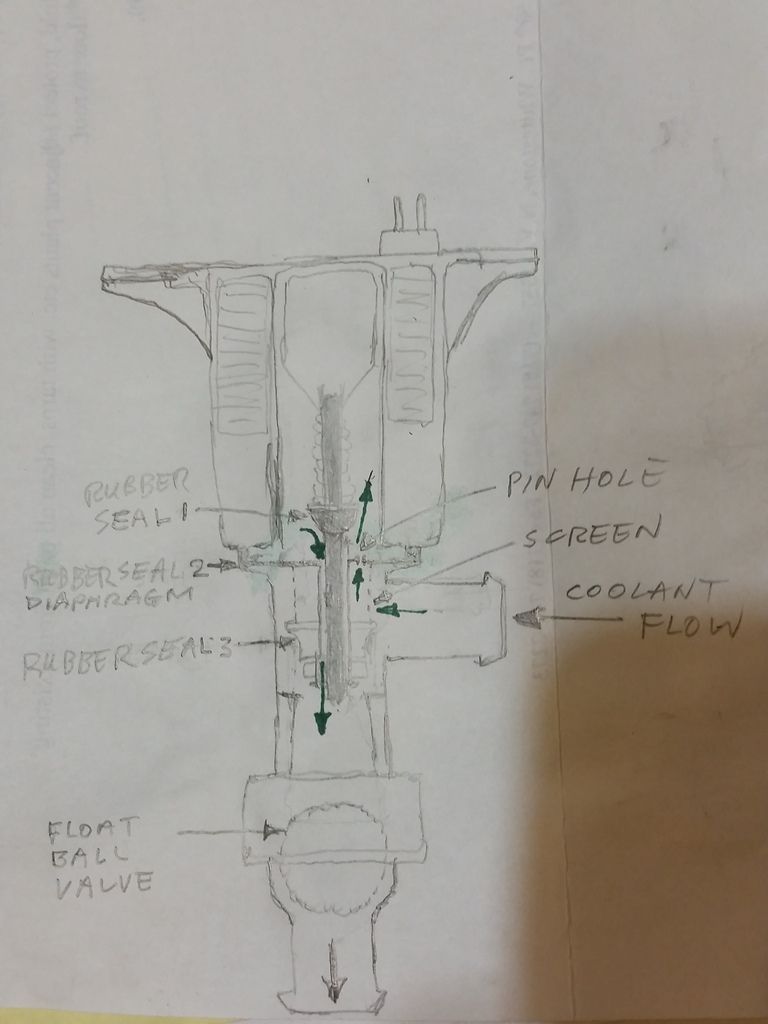

You can see this 3rd seal, a small tapered rubber plug on the shaft in this video https://youtu.be/AUKvBorGYxg as the shaft is pulled out. From what I can see, it seals the bushing opening in plunger/screen/diaphragm assembly when the solenoid is energized (extended).

__________________

85 300D turbo pristine w 157k when purchased 161K now 83 300 D turbo 297K runs great. SOLD! 83 240D 4 spd manual- parted out then junked Last edited by funola; 11-22-2016 at 11:52 AM. |

|

#26

|

|||

|

|||

|

I had that third seal also, it was just removed from the core I took apart.

I will try to get some pictures using my spare unit to better explain it. I can visualize stuff easily but have a hard time explaining it.

__________________

'85 300D - federal spec, built in late 84. 85 300D Complete AC System Rebuild |

|

#27

|

||||

|

||||

|

Quote:

Below is the only diagram I can find (2nd version starting Feb 1979), but the monovalve, item 12 is in the wrong place. It should be on the output side of the heater core. The aux pump is also not shown in the diagram.

__________________

85 300D turbo pristine w 157k when purchased 161K now 83 300 D turbo 297K runs great. SOLD! 83 240D 4 spd manual- parted out then junked |

|

#28

|

||||

|

||||

|

Quote:

__________________

85 300D turbo pristine w 157k when purchased 161K now 83 300 D turbo 297K runs great. SOLD! 83 240D 4 spd manual- parted out then junked |

|

#29

|

|||

|

|||

|

I certainly can't prove that the thermostat open/close pressure is different, it's just the best explanation for the behavior that I'm seeing that I can think of.

Nice drawing! I'll try to show you tonight what the difference I saw was- Essentially I had the spacer (not labeled in your drawing) between Rubber seal 1 and rubber seal 2. Which means that rubber seal 3 was pushed further down into the seating position. It's funny you mention CAD stuff, I've been looking around at laptops with digitizers built in to do some CAD structural designs and some 3d modeling for a non-MB automotive project I've been thinking about. Will probably wait until the black Friday sales to buy anything, if I decide to. My home PC is converted to an HTPC - which makes CAD work miserable.

__________________

'85 300D - federal spec, built in late 84. 85 300D Complete AC System Rebuild |

|

#30

|

|||

|

|||

|

Funola,

Here's some pictures of my spare monovalve in both configurations (incorrectly assembled and correctly assembled) with some measurements taken. This is all spare parts (thus the torn diaphragm - and i'm out of snap rings). I'll explain the pictures a bit later, short on time right now but I wanted to get them uploaded.

__________________

'85 300D - federal spec, built in late 84. 85 300D Complete AC System Rebuild |

|

| Bookmarks |

|

|