|

|

|

|

|

|

|

|

|

|

|

#1

|

|||

|

|||

|

W123 Monovalve disassembly and troubleshooting

Hi all,

I've been trying to fix my monovalve for quite some time. Currently the problem is that it's failing open, meaning I get hot water to the heater core, whenever the car gets completely to temperature. This means that after driving for a few minutes, I get full heat from the vents all of the time. I can still vary the fan speed, but I can't really run the air conditioning. I'm really not wanting to spend a ton of money to buy a NOS monovalve. I feel like there has to be a way to fix this, without resorting to eliminating the monovalve and replacing it with a manually operated valve. First, I'd like to go into terminology. In order to speak clearly, lets discuss what each part should be called (These terms are just my suggestions, but please stick to them to reduce confusion) Monovalve: Complete valving unit, including: Housing: Plastic, not pictured below. Coil: Plastic unit with copper windings. Not pictured below. Core: Silver cylindrical unit, pictured but not labeled below. Plunger Assembly: Rubber & brass unit. Contains the plunger, screen, and diaphragm (all pictured and labeled below) Diaphragm: Part that normally tears on aged units. Screen: Filter element Plunger: Actually forms the seal to cut off coolant flow. Linkage: Part of the core, plunger unit is attached to this. Weight: Steel weight that is moved by magnetic field induced by the coil - not visible without destructive tear down of core. I'll post more later today about the system, it's function, problems, and proposed solutions.

__________________

'85 300D - federal spec, built in late 84. 85 300D Complete AC System Rebuild |

|

#2

|

||||

|

||||

|

What is keeping the weight/ linkage/ spring assembly in the shell/core that requires cutting? I took the circlip out of my spare Bosch monovalve to have a look but the weight/ linkage/ spring assembly did not want to come out. Btw the weight is iron (everything else in the core- the shell, shaft, not sure about the spring, is non ferrous) and is the only part that is acted upon by the electromagnet/ coil. I tested the spring on mine and it requires 10 oz weight to stretch the spring. This is the force that retracts the weight/ linkage/ spring/ rubber plunger seal when power is removed from the monovalve to allow coolant flow.

I have a new understanding of monovalve operation since looking at your pics and taking mine apart again/ further. Contrary to what I used to think, coolant does enter the inside of the core via the shaft. The pinhole allows air to escape and coolant movement in and out of the core as it cools/ expands. If those passages are plugged with rust/ scale, it could hinder movement of the weight/ linkage/ spring/ rubber plunger seal assembly. A clean coolant system free of rust/ scale is paramount to monovalve health IMO. Never use plain water which promotes rust formation (pretty quickly). I took a bunch of pics and videos, will upload later.

__________________

85 300D turbo pristine w 157k when purchased 161K now 83 300 D turbo 297K runs great. SOLD! 83 240D 4 spd manual- parted out then junked Last edited by funola; 11-08-2016 at 09:48 PM. |

|

#3

|

||||

|

||||

|

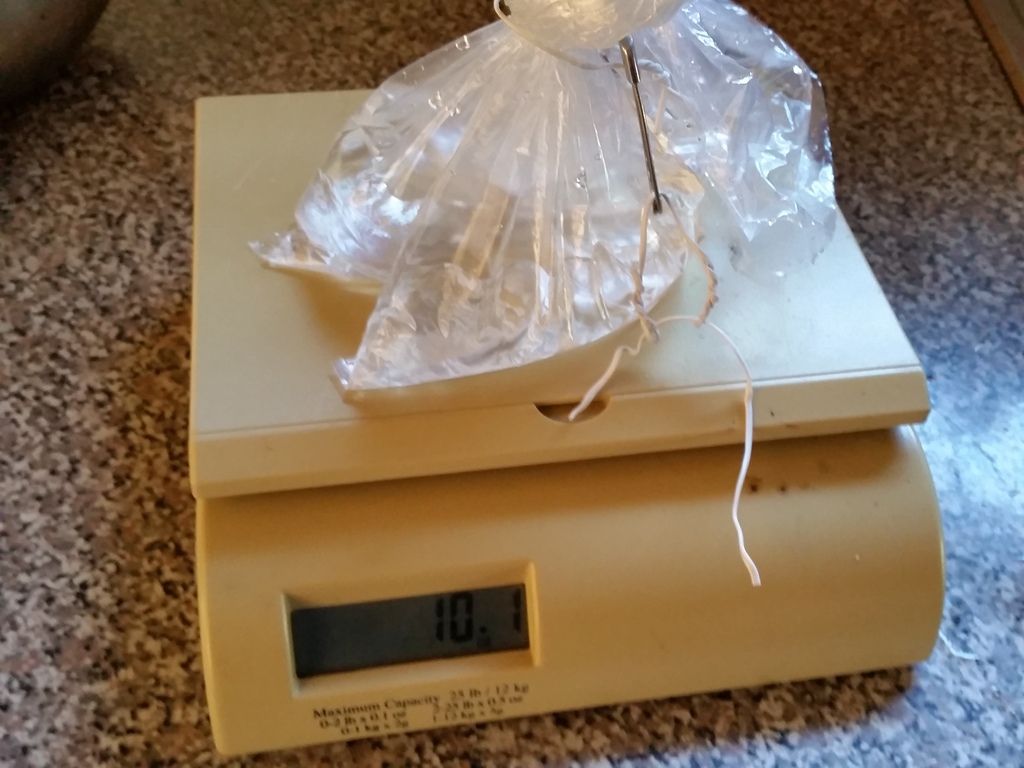

This was easy. Bag from grocery section, water, twist wire ties, digital scale

Edit: important to set it up so bag hangs straight down and not on one side, which makes it sticky and requires more water. This is a Bosch core. Would be interesting what the MTC unit is.  Took bag/ wire ties and weighed it.

__________________

85 300D turbo pristine w 157k when purchased 161K now 83 300 D turbo 297K runs great. SOLD! 83 240D 4 spd manual- parted out then junked Last edited by funola; 11-08-2016 at 04:08 PM. |

|

#4

|

|||

|

|||

|

The plunger/linkage is held in and requires cutting to extract because the core is made of two pieces. The outer bit is made of thin sheetmetal that was likely pressed into shape, but there is also a machined (probably) piece that was pressed in. If you look at IMG_0866 above (the 4th one attached, which shows the core cut open) - you can see I initially made a cut with a hacksaw about 3/4" from the plunger end. That cut is more than deep enough to cut through the outer housing, but it was running into the machined "plug" that was pressed then crimped in place. I guess it could be pulled apart, but I really don't see how you could get enough grip on the center piece to pull it out.

I think the only way to open a unit and reseal it would be to cut the flat end of the housing off, dismantle it, then braze it back together. I think you'd need to use a machinist's lathe to get a smooth enough cut, then run it back through the lathe to smooth the braze down enough to fit it through the coil. I lack both a lathe and brazing skills, so I can't really promise that would work

__________________

'85 300D - federal spec, built in late 84. 85 300D Complete AC System Rebuild |

|

#5

|

||||

|

||||

|

Is the cut open unit a MTC or Bosch?

__________________

85 300D turbo pristine w 157k when purchased 161K now 83 300 D turbo 297K runs great. SOLD! 83 240D 4 spd manual- parted out then junked |

|

#6

|

|||

|

|||

|

MTC. I didn't want to ruin a Bosch unit since I only have two.

__________________

'85 300D - federal spec, built in late 84. 85 300D Complete AC System Rebuild |

|

#7

|

||||

|

||||

|

The Bosch coil is 14 to 15 ohms, I measured my spare and the one in the car (also Bosch) and both have same resistance.

Will the MTC rubber seal/screen piece (comes off after removing circlip) fit the Bosch core? If the MTC unit has a heat issue, swapping its rubber piece to the Bosch core will eliminate that problem.

__________________

85 300D turbo pristine w 157k when purchased 161K now 83 300 D turbo 297K runs great. SOLD! 83 240D 4 spd manual- parted out then junked |

|

#8

|

|||

|

|||

|

Thanks, I'll check mine and report back.

The screen/seal/plunger assembly is interchangeable between the MTC and Bosch units. I've been running the MTC assembly on a Bosch core. The only problem I noticed was that you may not be able to run the same number of washers behind the circlip. I'm not running any washer there currently. I suppose that could be a problem, but I can't really imagine why. Maybe I'll try to fit one washer by sanding down the spacer behind the screen assembly. I won't get time to work on the car at all tonight probably, will report back once I do.

__________________

'85 300D - federal spec, built in late 84. 85 300D Complete AC System Rebuild |

|

#9

|

||||

|

||||

|

Washers behind circlip? No washer behind circlip on mine. There is a plastic spacer/bushing, with three internal "tooth" to allow coolant to flow into the inside of the core.

__________________

85 300D turbo pristine w 157k when purchased 161K now 83 300 D turbo 297K runs great. SOLD! 83 240D 4 spd manual- parted out then junked |

|

#10

|

|||

|

|||

|

Well. That might be my problem then. I might have that spacer in the wrong place.

__________________

'85 300D - federal spec, built in late 84. 85 300D Complete AC System Rebuild |

|

#11

|

||||

|

||||

|

Video of the core being extended by hand and side to side wiggle. Does the MTC have similar wiggle? Wiggle indicates clearance between the weight and the core. If the MTC has similar wiggle, I doubt the weight jamming due to heat expansion is an issue.

https://www.youtube.com/watch?v=gTSBtaqlNQw

__________________

85 300D turbo pristine w 157k when purchased 161K now 83 300 D turbo 297K runs great. SOLD! 83 240D 4 spd manual- parted out then junked |

|

#12

|

|||

|

|||

|

I don't have a intact MTC unit. Just two used Bosch ones (remember I destroyed the MTC unit to see the internals)

I pulled my spare Bosch core out of the rust soak tonight. It is more free to wiggle now but doesnt appear to be as free as your video indicates. I put it in some white vinegar just now, I plan to let it sit for 30 minutes or so to try to disolve any calcium buildup. Will post back later

__________________

'85 300D - federal spec, built in late 84. 85 300D Complete AC System Rebuild |

|

#13

|

||||

|

||||

|

Quote:

__________________

85 300D turbo pristine w 157k when purchased 161K now 83 300 D turbo 297K runs great. SOLD! 83 240D 4 spd manual- parted out then junked |

|

#14

|

|||

|

|||

|

I can subjectively tell you that yes, it's weaker - though since I deformed the housing opening it up, the weight doesn't slide smoothly in the housing anymore.

__________________

'85 300D - federal spec, built in late 84. 85 300D Complete AC System Rebuild |

|

#15

|

||||

|

||||

|

Did you check if the spacer is in the wrong place?

__________________

85 300D turbo pristine w 157k when purchased 161K now 83 300 D turbo 297K runs great. SOLD! 83 240D 4 spd manual- parted out then junked |

|

| Bookmarks |

|

|