|

|

|

|

|

|

|

|

|

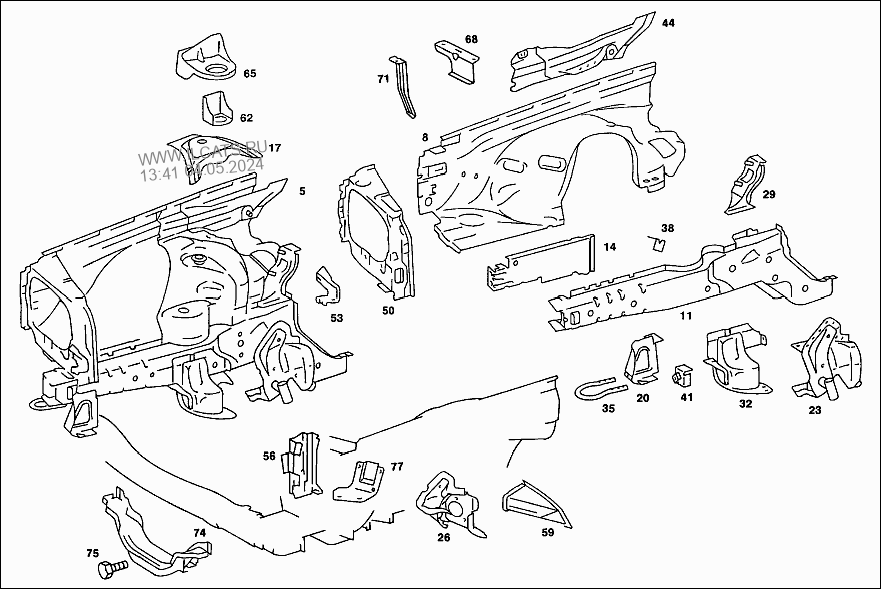

|

|

#1

|

|||

|

|||

|

Cracked Front Body to Subframe Mount - End of the Road?

My daily driver 1974 W115 240D started wearing the edges of its front tires pretty badly. I chalked it up to bad control arm bushings and the curvy mountain road I drive every day.

I finally decided it was time to tear into the front end. When inspecting the subframe mounting bushings I noticed a crack all the way through the driver's side rear mount point on the body for the front subframe. It's all the way through. I also noticed some odd, ah, craftsmanship where perhaps the mount has already been modded. When I put a pry bar to it, I can see the crack open and the subframe shift. I'm guessing this is the cause of my tire wear. Has anyone seen this before? Is it fixable or weldable? It's definitely off the road now... yikes! If it is fixable, is it worth it? This is a daily driver with some rust--it's been a great car, but I'm worried this is likely the end of the road for it. Thank you for the advice!

|

|

#2

|

|||

|

|||

|

For your safety and the safety of other drivers I would recommend that you park your car. Cracks in the frame are seldom repaired adequately to be safe.

|

|

#3

|

|||

|

|||

|

Safety is definitely the highest priority. The safety of a repair--let alone is it even possible--is what I'm questioning. Ugh... anyone looking for a parts car?

|

|

#4

|

||||

|

||||

|

Anything can be repaired. Just how and at what cost are the questions.

One option might be to find a car with rust free supports. Cut those out and weld them onto your car. Or if there is a good shop in your area, perhaps they could fabricate the replacement. This would cost some $$$ and you would have to decide whether rest of car would make it worthwhile I wouldn't be concerned about proper weld repairs. Mercedes 107s were delivered with badly designed subframe mounts. These were repaired by welding on reinforcement plates. On my 300d. Part of my rear frame rails had rusted. A local shop fabbed new pieces to fit. This some time ago and still good. Maybe see if you can find another 240d cheap and make one good one from the two! Good luck whatever you decide. |

|

#5

|

|||

|

|||

|

That looks weldable to me as long as you can get to it to clean it well. After its welded you will want to put eyes on it to make sure it doesn't crack again nearby, but I have definitely driven much worse.

__________________

1985 300 TD 448K 1984 300 TD 278K 1983 240D euro 240k 1994 f-250 idi turbo 330K 1986 f-350 IDI 1987 F-350 IDI 1985 JD 1050 4wd 1965 IH 3660 |

|

#6

|

||||

|

||||

|

I agree it should be repairable.

__________________

[SIGPIC] Diesel loving autocrossing grandpa Architect. 08 Dodge 3/4 ton with Cummins & six speed; I have had about 35 benzes. I have a 39 Studebaker Coupe Express pickup in which I have had installed a 617 turbo and a five speed manual.  [SIGPIC] [SIGPIC]..I also have a 427 Cobra replica with an aluminum chassis. |

|

#7

|

|||

|

|||

|

While fixable perhaps you might wonder about the rest of the frame. Trust me, there is more rust to be found. In my state it is not legal to weld the frame. A good system that keeps You from side swiping Me. No one on this forum can judge your welding skills, make sure your repair is better than new.

|

|

#8

|

||||

|

||||

|

While I agree that this pictures area looks repairable, I also believe this a tip of the iceberg as far as rust. Judging by the condition of the other parts I see in the pictures. I would get this car up on a lift and really start going over the bottom carefully, remember, rust can hide under the undercoating etc. you only really ever see 10% of it. Regardless, the car is still worth $$$ as a parts car. IF you get another keep this one off to the side and you be happy you did. I can not tell you how many parts I have gotten off my parts cars that would have cost me major $$$ any other way.

|

|

#9

|

||||

|

||||

|

Is there any chance that that support is available as a replacement part from MB or aftermarket? I didn't try and identify it, but it might be worth checking epc. I would scrape off some of the crud above that bracket (above arrows in pic above). If that is also cracked, then.........

__________________

Graham 85 300D |

|

#10

|

||||

|

||||

|

Jb weld mixed with 5 min epoxy will work just fine.

__________________

|

|

#11

|

||||

|

||||

|

Yeah, then cover it with undercoating and some dirt - Then sell car to some unsuspecting sucker.

That's the kind of thing a nasty twit would do.

__________________

Graham 85 300D |

|

#12

|

|||

|

|||

|

Thank you all for the comments and thoughts. I've been chasing some rust on the body and floor pans, but the frame (until now) has been solid.

I do have a parts car and will look at the mount point there. If (and that's a big IF) I go for the repair, it will be professionally welded and braced. No JB Weld on this and certainly not resale without full disclosure. Hopefully, that was just a poor joke... |

|

#13

|

|||

|

|||

|

Kind of looks like a flexing or stressing type of crack. Possibly caused from the lack of support from the really rusted out area of the part.

Probe the frame in the area of the steering box. Have someone turn the steering wheel back and forth while observing for frame movement. A favorite place many of these got weak. Floor pans also bad. Perhaps it is time for another car. |

|

#14

|

||||

|

||||

|

I agree with Barry that the mount's lower part rusted away placing additional stress on the upper part of the mount causing it to crack. I too would be concerned about the steering box mounting.

And looking at your pics I see there is a additional reinforcing plate bolted to the frame using the steering box bolts - my car does not have this. You can see it clearly in the 2nd pic, right behind the brake line bracket. Me thinks this was to brace up an already weak, rusted area in order to stabilize the steering box. As Barry pointed out this is a weak point for W115s. Pull that plate off and take a look under there. NOTE: Looking at the 2nd pic again it appears the steering box's top mounting bolt's head is broken off, unless it's recessed into the plate.

__________________

- Greg - 1973 220D, The Prodigal Benz 1974 240D Last edited by gmog220d; 03-01-2020 at 11:49 AM. |

|

#15

|

||||

|

||||

|

The mention of driving on mountain roads makes a welded repair ominous.

I welded up a rusted and cracked rear cross member but it was one crack and it was kind of a square tube which means it was easy to make the reinforcing plates. Even with that simpler issue then yours nearly everyone said to junk the Car. No one has mentioned it but part of the issue with repairing yours would be lining it back up. You have a parts car to take dimensions from. That also means after you take dimensions you have a parts car you could actually to cut well beyond the cracked areas and cut out a whole section of the parts Car and then weld that on using your previous measurements to line it up. The parts car give you another option. I bought a Harbor Freight Flux core welder that I did not know how to use even welding flat and had to do it welding upwards. I ended up grinding off 90 percent of what I wended due to bad welding. Ground the welds on the tubing flat and welded over the flat repair plates. Mine was a much simpler job and obviously the front end is more critical and deals with more weight on it especially when you brake the weight shifts forward onto the front.

__________________

84 300D, 82 Volvo 244Gl Diesel |

|

| Bookmarks |

|

|