|

|

|

|

|

|

|

|

|

|

|

#16

|

||||

|

||||

|

Quote:

__________________

1981 240D 4sp manual. Ivory White. |

|

#17

|

||||

|

||||

|

Yes ~ using a bar to tension the alternator when setting the belt tension is the usual culprit .

No one likes chattering / squealing drive belts so the natural inclination is to set them *really* tight, like the 'E' string on a guitar . Keeping after oil leaks too helps prevent belt slip, try to get the average customer to grasp this basic concept . My brother thinks allowing his 300SDL to be filthy oily under the hood is macho or some foolishness, right now the fuel warmer on it's OM603 weeps and he refuses to clean it nor let me clean it / bypass the weepy device, of course when the motor mounts collapse and the fuel hoses and drive belts all need replacing it'll be the car's fault not his....

__________________

-Nate 1982 240D 408,XXX miles Ignorance is the mother of suspicion and fear is the father I did then what I knew how to do ~ now that I know better I do better |

|

#18

|

||||

|

||||

|

Quote:

I've always used a cricket to set belt tension. That said, there are some inconsistencies. You're meant to use a section of belt with the greatest distance between pulleys, but on the alt belt, you've got three pulleys and getting an accurate read can be difficult. I'm aware of the 1/2" deflection method, though I prefer precision when possible. I've certainly been guilty of over-tightening in the past.

__________________

1981 240D 4sp manual. Ivory White. |

|

#19

|

||||

|

||||

|

Quote:

It was just stupid expensive. I put a GMB pump in and it only cost me $30.

__________________

79 300TD “Old Smokey” AKA “The Mistake” (SOLD) 82 240D stick shift 335k miles (SOLD) 82 300SD 300k miles 85 300D Turbodiesel 170k miles |

|

#20

|

||||

|

||||

|

Oh, yeah ~ when I was a young pup I'd use a 4' long crowbar to tension alternators, luckily a few old timers took me aside and explained things .

Peach Parts is good but my last V-Belt order was FU-BAR ~ all 9MM width belts and the OM616 & 617 engines require 10MM so they squeaked a fair bit, I didn't have the time to return them . I know I should have caught this when I willcalled the part order but when dealing with a house fire, Foster boys and three daily drivers all showing badly cracked belts at the same time, one has to go with the flow . I always carry the last set of V belts in the trunk as spares, they're not fun to change using the factory tool kit but it's do - able and beats walking . One more reason to keep things clean under the hood .

__________________

-Nate 1982 240D 408,XXX miles Ignorance is the mother of suspicion and fear is the father I did then what I knew how to do ~ now that I know better I do better |

|

#21

|

|||

|

|||

|

the usual failure I have encountered is not flushing the engine during a water pump job.

__________________

2012 BMW X5 (Beef + Granite suspension model) 1995 E300D - The original humming machine (consumed by Flood 2017) 2000 E320 - The evolution (consumed by flood 2017) |

|

#22

|

||||

|

||||

|

Well, I installed the new pump. Turns out there were two noises.

When attempting to pinpoint the origin using a length of fuel hose, it seems to be right above the water pump. It's a higher pitched sound, sometimes barely discernible from the cabin, and only on startups. Though with the hood up, I can hear it over the diesel clatter. I'm not entirely clear what's back there. Diseasel, you suggested "vacuum pump, idler sprocket, chain tensioner, or timing chain." I listened at the vacuum pump, and unless it's throwing the noise, which I suppose is possible given the amount of circulating liquid just behind it, it doesn't seem the likely culprit. Idler sprocket, I'm unfamiliar with... Chain by way of tensioner, I certainly am. I believe there's a tensioning rail behind the pump though this is all new territory for me. The OEM tensioner is about $240 so granted I'm a little reluctant to throw one at the problem, unless I can be certain.

__________________

1981 240D 4sp manual. Ivory White. |

|

#23

|

||||

|

||||

|

Quote:

__________________

Current stable: 1995 E320 149K (Nancy) 1983 500SL 120K (SLoL) Black Sheep: 1985 524TD 167K (TotalDumpster™) Gone but not forgotten: 1986 300SDL (RIP) 1991 350SD 1991 560SEL 1990 560SEL 1986 500SEL Euro (Rusted to nothing at 47K!) |

|

#24

|

||||

|

||||

|

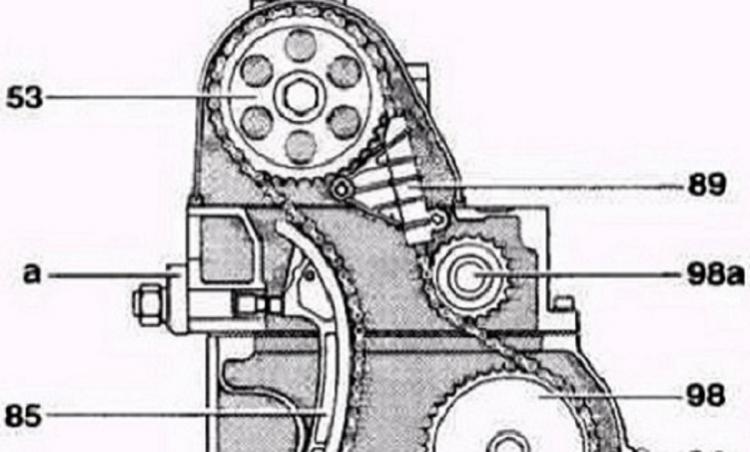

This is also referred to as the "timing device?"

Driving the IP?

__________________

1981 240D 4sp manual. Ivory White. |

|

#25

|

||||

|

||||

|

No. The idler sprocket is in head. The timing device is the big sprocket # 98.

__________________

Current stable: 1995 E320 149K (Nancy) 1983 500SL 120K (SLoL) Black Sheep: 1985 524TD 167K (TotalDumpster™) Gone but not forgotten: 1986 300SDL (RIP) 1991 350SD 1991 560SEL 1990 560SEL 1986 500SEL Euro (Rusted to nothing at 47K!) |

|

#26

|

||||

|

||||

|

Well this is embarrassing and mildly demoralizing...

I pulled the valve cover to take a look down the chain well. Everything looked normal, chain tension felt fine. While buttoning everything up, I noticed my alternator was sitting a little cocked. I grabbed it and found I was able to shake it. Not good. Climbed underneath and removed the lowest bolt (the one that controls pivot), and found this:  Here's the bolt:  Here's where the bracket/alternator bit into the bolt:  And here's what I did as a temporary measure:  I suspect the off-angle pulley is what trashed my original water pump, Now that I've straightened the thing out, I'm back to normal. Fortunately, my new water pump is still fine. I'm at a bit of a loss here... That bolt seems like the wrong one, yet it's all I've ever had. The threaded portion is far too long and I suspect the hardness of the steel (8.8) was either insufficient (denting of the bolt), or too much, rifling of the alternator bore hole. I'm not really sure how to proceed here.

__________________

1981 240D 4sp manual. Ivory White. |

|

#27

|

|||

|

|||

|

Replace the alternator and bolt is the easiest. Next option would be drilling, install a bushing (s) and replace the bolt. You'll see this repair quite often on rebuilt units.

The 8,8 bolt is the correct hardness. Somewhere down the line, whenever the belt was replaced/adjusted, the long bolt did not get properly torqued. A few million revolutions, diesel vibrations, stress from charging, etc. caused the steel bolt to wear away the softer alternator casting. Not unusual. I've also seen the mounting bracket erode leaving a gap between the long spacer of the alternator and the two "ears" of the bracket. This will allow the alternator to slide front to rear when mounted. Usually a thin washer is inserted between the rear of the alternator spacer and the bracket to correct. The alternator should fit snug between the ears of the bracket. Not, "Get the bigger hammer" tight but it should have to be worked into place. The long bolt is the correct one. Having the extra threads also makes it handy to add an additional ground/earthing strap or a second nut to act as a lock.

__________________

“Whatever story you're telling, it will be more interesting if, at the end you add, "and then everything burst into flames.” ― Brian P. Cleary, You Oughta Know By Now Last edited by Mike D; 04-10-2021 at 09:20 PM. |

|

#28

|

||||

|

||||

|

Quote:

Unfortunately, that alternator is new. I replaced it last April, so whatever caused that erosion, did it quickly. Which” ears of the bracket” are you referring to? Is this the pivot bolt mounting area? If there’s something for which I can compensate, I’d like to get on that immediately. It looks like I’ll be getting a new alternator Re: the long bolt, I’m not sure I follow. Those extra threads are lost in the bore. The bolt length seems to be correct, instead it’s the length of the threaded portion that seems to be the issue. If this is the correct bolt, I can’t understand for the life of me why the weight of the alternator and the force of the belt pulling against the pivot would be resting on threads rather than a solid bolt shank. You can see in the photos above where those threads have been flattened.

__________________

1981 240D 4sp manual. Ivory White. |

|

#29

|

|||

|

|||

|

My mistake regarding exposed threads. I was thinking of the gasoline engines which leave threads exposed. You are correct, the diesel engine mount is much thicker and the threads are indeed buried in the bracket.

__________________

“Whatever story you're telling, it will be more interesting if, at the end you add, "and then everything burst into flames.” ― Brian P. Cleary, You Oughta Know By Now |

|

#30

|

||||

|

||||

|

No sweat Sherm ;

Just schelpp on down to the local P-A-P and grab the correct bolt and perhaps another undamaged alternator, swap over your new brush set and Robert is your Father's brother.... I'd sure I have a spare alternator I'd give you if you're interested, I won't be available until next week though . Millions of 1960's & 1970's Chevrolets has this same issue from new ~ the old cheaply made Delcotron alternator made a distinct sound as it rattled on down the road . Any time you have more than a few threads sticking out you should take a closer look ~ hardware is important and few grasp this .

__________________

-Nate 1982 240D 408,XXX miles Ignorance is the mother of suspicion and fear is the father I did then what I knew how to do ~ now that I know better I do better |

|

| Bookmarks |

| Thread Tools | |

| Display Modes | |

|

|