|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

LinkBack | Thread Tools | Display Modes |

|

#31

|

||||

|

||||

|

OM60x bottom injection pump cover plate screw removal

For the bottom injection pump cover plate, I use a Right Angle Screwdriver

8 Piece Right Angle Screwdriver with this set of bits 32 Piece Magnetic Driver Guide Kit Special note: As needed, I grind 2 - 3 MM from the bottom of the required bit, to shorten for easier access. .

__________________

ASE Master Mechanic asemastermechanic@juno.com Prototype R&D/testing: Thermal & Aerodynamic System Engineering (TASE) Senior vehicle instrumentation technician. Noise Vibration and Harshness (NVH). Dynamometer. Heat exchanger durability. HV-A/C Climate Control. Vehicle build. Fleet Durability Technical Quality Auditor. Automotive Technical Writer 1985 300SD 1983 300D 1984 190D 2003 Volvo V70 2002 Honda Civic https://www.boldegoist.com/ |

|

#32

|

||||

|

||||

|

Special tool for running your diesel engine without the Turbo installed

Special tool for running your diesel engine without the Turbo installed

Special tool for running your diesel engine without the Turbo installed .

__________________

ASE Master Mechanic asemastermechanic@juno.com Prototype R&D/testing: Thermal & Aerodynamic System Engineering (TASE) Senior vehicle instrumentation technician. Noise Vibration and Harshness (NVH). Dynamometer. Heat exchanger durability. HV-A/C Climate Control. Vehicle build. Fleet Durability Technical Quality Auditor. Automotive Technical Writer 1985 300SD 1983 300D 1984 190D 2003 Volvo V70 2002 Honda Civic https://www.boldegoist.com/ |

|

#33

|

||||

|

||||

|

More data on topic

home made tools and equipment... | The H.A.M.B.

Mig Welding, Stick Welding, Fabricating Tips and Techniques - If You Want To Weld, Weld Like You Mean It! Serious Question: Need Info on Car Tilter .

__________________

ASE Master Mechanic asemastermechanic@juno.com Prototype R&D/testing: Thermal & Aerodynamic System Engineering (TASE) Senior vehicle instrumentation technician. Noise Vibration and Harshness (NVH). Dynamometer. Heat exchanger durability. HV-A/C Climate Control. Vehicle build. Fleet Durability Technical Quality Auditor. Automotive Technical Writer 1985 300SD 1983 300D 1984 190D 2003 Volvo V70 2002 Honda Civic https://www.boldegoist.com/ |

|

#34

|

||||

|

||||

|

Finger saving method of fitting tight boots on axle shafts

(A special tool to chuck away when you are done - don't fill up your life with crap!)     Not 100% necessary but for people with weaker hands or perhaps rheumatism not such a bad way to do it. I see no point in being butch and macho about it and ripping your finger nails out on stubborn bits of rubber! But you might want to try some KJ jelly first... W201 annular axle re-boot – much easier than W123 homokinetic axles!

__________________

1992 W201 190E 1.8 171,000 km - Daily driver 1981 W123 300D ~ 100,000 miles / 160,000 km - project car stripped to the bone 1965 Land Rover Series 2a Station Wagon CIS recovery therapy! 1961 Volvo PV544 Bare metal rat rod-ish thing I'm here to chat about cars and to help others - I'm not here "to always be right" like an internet warrior Don't leave that there - I'll take it to bits! |

|

#35

|

||||

|

||||

|

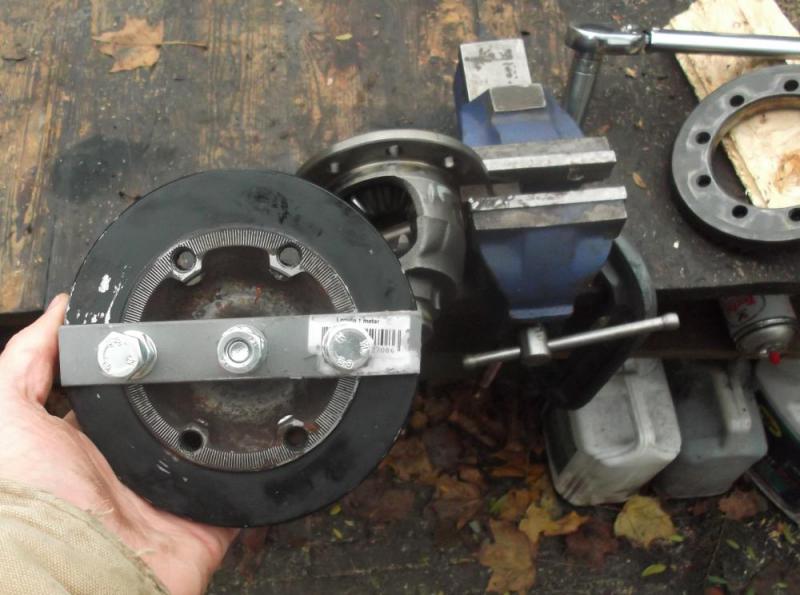

This almost doesn't qualify as a special tool. But it allows you to spin and check the breaking torque on differential side gears that have annular axles fitted - so from say late W123 and W201 times

The W201 differential refresh thread And that's something else to throw away when you are done. Honestly folks don't keep junk like this in your life - it isn't healthy!

__________________

1992 W201 190E 1.8 171,000 km - Daily driver 1981 W123 300D ~ 100,000 miles / 160,000 km - project car stripped to the bone 1965 Land Rover Series 2a Station Wagon CIS recovery therapy! 1961 Volvo PV544 Bare metal rat rod-ish thing I'm here to chat about cars and to help others - I'm not here "to always be right" like an internet warrior Don't leave that there - I'll take it to bits! |

|

#36

|

||||

|

||||

|

Quote:

|

|

#37

|

|||

|

|||

|

Spreading device 126 589 00 31 00

...and measuring instrument 126 589 08 21 00. These are for working on late W123 and W201 differentials (at least), those without lateral bearing caps. They apply and measure horizontal stretch to the differential housing to allow the large c-clips at the sides to be removed and installed correctly. These are my reverse-engineered plans for tools of equivalent function. A welder is definitely required, and I used a metal lathe. A drill press will work as long as one can find a properly-sized piece of round stock to press on the differential. The only really critical dimensions are the location of the screw and the location of the holes for bolting the tool onto the differential case.

The measuring tool is also useful for earlier differentials with lateral bearing caps. Construction of the tools is described in my car's build thread. |

|

#38

|

||||

|

||||

|

Quote:

I had to resort to very careful use of this =>  To do a similar job The W201 differential refresh thread

__________________

1992 W201 190E 1.8 171,000 km - Daily driver 1981 W123 300D ~ 100,000 miles / 160,000 km - project car stripped to the bone 1965 Land Rover Series 2a Station Wagon CIS recovery therapy! 1961 Volvo PV544 Bare metal rat rod-ish thing I'm here to chat about cars and to help others - I'm not here "to always be right" like an internet warrior Don't leave that there - I'll take it to bits! |

|

#39

|

||||

|

||||

|

Another differential tool / gearbox tool

How to hold a yoke still =>

Semi circle cut into a big thick gate hinge Drill hole(s) for attachment to yoke

__________________

1992 W201 190E 1.8 171,000 km - Daily driver 1981 W123 300D ~ 100,000 miles / 160,000 km - project car stripped to the bone 1965 Land Rover Series 2a Station Wagon CIS recovery therapy! 1961 Volvo PV544 Bare metal rat rod-ish thing I'm here to chat about cars and to help others - I'm not here "to always be right" like an internet warrior Don't leave that there - I'll take it to bits! |

|

#40

|

||||

|

||||

|

Top quality ...

...high end precision door window mirror installation tool

This helps you from cracking the mirror on the flimsy plastic backing as you shove it into the ball socket

__________________

1992 W201 190E 1.8 171,000 km - Daily driver 1981 W123 300D ~ 100,000 miles / 160,000 km - project car stripped to the bone 1965 Land Rover Series 2a Station Wagon CIS recovery therapy! 1961 Volvo PV544 Bare metal rat rod-ish thing I'm here to chat about cars and to help others - I'm not here "to always be right" like an internet warrior Don't leave that there - I'll take it to bits! |

|

#41

|

||||

|

||||

|

The mad (tw)hatter

I think I picked this tip up on the metal meet forum (I can't remember the guy's name so I can't take credit for it - I can take credit for the wonderful art work however!)

It has turned out to be quite useful for metal shaping recently. It is just a lump of tropical hardwood I saved from an old window frame shaped into a bat with a handle. A leather belt has been stretched round the nose to provide a bit of cushioning. The point of this bat is to help with (very) rough sheet metal formation. The addition of the leather belt helps to iron out your mistakes and poorly aimed blows!

__________________

1992 W201 190E 1.8 171,000 km - Daily driver 1981 W123 300D ~ 100,000 miles / 160,000 km - project car stripped to the bone 1965 Land Rover Series 2a Station Wagon CIS recovery therapy! 1961 Volvo PV544 Bare metal rat rod-ish thing I'm here to chat about cars and to help others - I'm not here "to always be right" like an internet warrior Don't leave that there - I'll take it to bits! |

|

#42

|

||||

|

||||

|

Modifications to cheapo bench top sand blasting cabinet

If you have ever bought one of these cheap sand blasting cabinets the chances are you have probably wanted to drop kick the bloody thing into oncoming traffic...

The biggest problem I have with them is that (because you can't see a thing inside them) the sand ends up sitting elsewhere in the cabinet and the pick up tube just sucks air through it. Exaggerated picture of the problem => I have tried filling the cabinet up with more sand but even that doesn't seem to work. To make it more useful (before deciding to build a decent sized cabinet) I made a simple funnel modification to the base. I built some legs too Even painted the bits! Punching holes for rivets Had to make a former for "shape adjustments" (!) Bashed it a bit Much better now Sand now falls into a deeper funnel which means the pick up tube doesn't run dry

__________________

1992 W201 190E 1.8 171,000 km - Daily driver 1981 W123 300D ~ 100,000 miles / 160,000 km - project car stripped to the bone 1965 Land Rover Series 2a Station Wagon CIS recovery therapy! 1961 Volvo PV544 Bare metal rat rod-ish thing I'm here to chat about cars and to help others - I'm not here "to always be right" like an internet warrior Don't leave that there - I'll take it to bits! |

|

#43

|

||||

|

||||

|

Not really a special tool but...

...you can't beat a movable work chest / table!

Being a bit taller than the average chap (and getting a bit older than the average chap too) I'm fed up with having to stoop down when I'm welding smaller parts or cutting metal. So I built this=> It is based round a cheap tool storage solution I picked up a few years back - a cabinet with plastic tray / drawers. Loads of storage for crap! Blokes like me need space for crap - you never know when you are going to need it and if you can find a way of categorising it (even loose categorisations are a start) the chances of finding the suitable crap you are looking for at any given moment in time increases! Finding the crap you know you have somewhere stops the need to go off to the shop to buy yet more crap that you'll probably misplace somewhere... Anyway there you have it a nice - custom height - work bench on wheels that is ideal for cutting sheet metal and storing crap. What more could a chap want?

__________________

1992 W201 190E 1.8 171,000 km - Daily driver 1981 W123 300D ~ 100,000 miles / 160,000 km - project car stripped to the bone 1965 Land Rover Series 2a Station Wagon CIS recovery therapy! 1961 Volvo PV544 Bare metal rat rod-ish thing I'm here to chat about cars and to help others - I'm not here "to always be right" like an internet warrior Don't leave that there - I'll take it to bits! |

|

| Bookmarks |

|

|