|

|

|

|

|

|

|

|

|

|

|

#1

|

||||

|

||||

|

New table saw time

I was saving up for a new rigid table saw but I came across this gem at an estate sale(where I usually buy my tools) and they wanted $250 for it but I offered $75 and it's now mine. It's from '59 or so. I really like the engine turned panel and the shape of it all. It's a 10" with tilting arbor. Plus it's a craftsman tool made when craftsman actually made good stuff. This will last me a lifetime. Now to get a blade guard, splitter, and upgrade the fence and I'll be good to go.

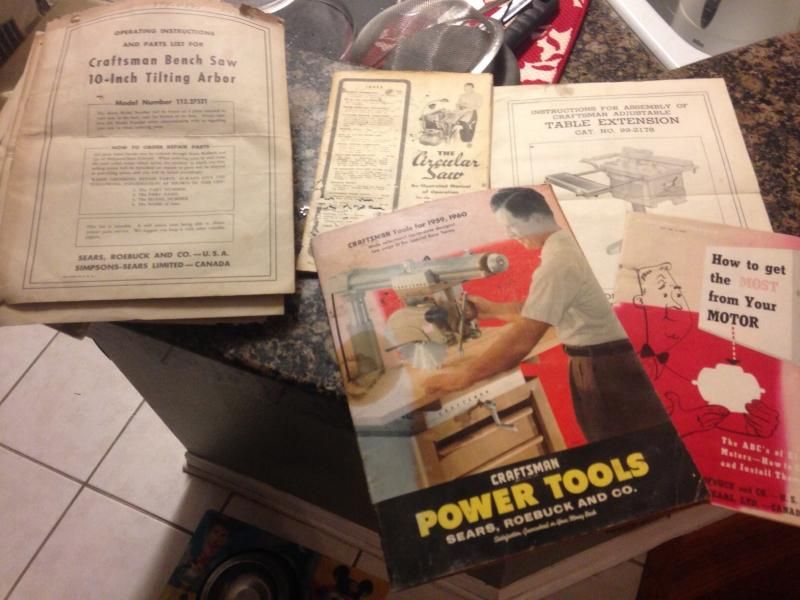

And this cool stuff that I found in the garage with the saw

|

|

#2

|

||||

|

||||

|

Not bad. That's a good saw. My dad used to have something like that. I've had two ten inch Rigid portables, my first one lasted about 6 or 7 years, I got one of these when the motor went south on and I couldn't get a replacement. Just as well as I like this saw more than the first one:

Table Saws: Ridgid Table Saws & Components 15-Amp 10 in. Heavy-Duty Portable Table Saw with Stand R4513

__________________

1986 300SDL, 362K 1984 300D, 138K |

|

#3

|

|||

|

|||

|

Quote:

Unfortunatly all the table saws I like are not easily transported. If they are to stay at one location for a good period of time is still not that bad. They are just too much of a handful for true general mobility. I need their accuracy and power too much to change my ways. |

|

#4

|

||||

|

||||

|

I hear you, I too like the big stationary saws. With one big company I was with, we would have an almost cabinet shop level tablesaw set up, outfeed table, fancy fence, I seem to recall it was the Biesemeyer brand.

But these days I need to be mobile and this new rigid is not bad all in all. Sometimes I need to make room in my shop so I can work on my car during the winter. Being able to fold the saw and roll it out-of-the-way is pretty handy.

__________________

1986 300SDL, 362K 1984 300D, 138K |

|

#5

|

||||

|

||||

|

I have my dad's table saw. I think it is similar to yours, though maybe not as big. It still works great along with his skil saw from 1947 and my grandpa's 1/2" drill which if it binds will about kill you its so powerful.

__________________

[SIGPIC] Diesel loving autocrossing grandpa Architect. 08 Dodge 3/4 ton with Cummins & six speed; I have had about 35 benzes. I have a 39 Studebaker Coupe Express pickup in which I have had installed a 617 turbo and a five speed manual.  [SIGPIC] [SIGPIC]..I also have a 427 Cobra replica with an aluminum chassis. |

|

#6

|

|||

|

|||

|

Few tools give me concern. That said good 3/4 inch drills with larger hole saws especially almost scare me. When the hole saws grab you are at their mercy.

I have even mounted really long bars across them when possible to maintain some semblance of control. You really need the leverage to stop the geared down torque effect with a jammed bit. Your hands or fingers pinched are a poor substitute. Try a one inch old powerhouse of a drill. Those I refuse to handhold. The other tool I more than respect is a chain saw. They are somewhat safer than they once where but one misjudgement could still get you torn up pretty bad. I would also like to see the automatic blade stops on table saws with skin contact made mandatory. I am fairly confident in my own use of table saws but fear for others. Once mandatory the price would drop. I have watched too many others use them in a dangerous fashion unfortunately.. At least buy a purpose designed table wax to lessen the push force required. Keep the work area clear as falling on the blade is another remote possibility. Once mandatory the incorporated blade stop prices would substantially drop. I fortunately own many aftermarket accessories that further limit my exposure when using table saws . I just have used table saws too much not to. The problem is they are generally too expensive for the casual user. I still have all my fingers incidentally over about 60 year of table saw usage. I purchased my first little nine inch Rockwell table saw when about fifteen years old and still have the little delco 3/4 horse motor I purchased for it. |

|

#7

|

||||

|

||||

|

Pfffft! Blade guards are for wusses! Besides, isn't lopping off part of a digit a job requirement?

Nice find. Love that fence set up! I dig old tools, got a bunch from my grandfather.

__________________

1980 300TD-China Blue/Blue MBTex-2nd Owner, 107K (Alt Blau) OBK #15 '06 Chevy Tahoe Z71 (for the wife & 4 kids, current mule) '03 Honda Odyssey (son #1's ride, reluctantly) '99 GMC Suburban (255K+ miles, semi-retired mule) 21' SeaRay Seville (summer escape pod) |

|

#8

|

||||

|

||||

|

I have never liked the table saw blade guards. Nobody I know leaves them in place. The blade stop is a different mechanism. It can sense contact with flesh and throws a brake that I think might be made of lead into the blade stopping it like right now. It's a one use thing, needs to be replaced at a cost of about $250 IINM.

Here's a vid about it. They said that almost 10 people a day take off a finger with a table saw. Also said the mechanism is only $60 to replace: https://www.youtube.com/watch?v=eiYoBbEZwlk I've thought about it, I've not done it as I wonder what kind of false alarm problems it might have. Replace a couple of those thing on false alarms and it could get annoying. I treat that blade like some sort of Hindu destroyer God. Always mindful of where it and my hands are. Only flick of bits of wood while it's running with a long stick. Use push sticks whenever it's at all dicey. My dad had all ten when he died, I'm on track for that. But dang, in my dad's generation, them old boys were hard core. First thing they'd do when they bought a skil saw was to take the blade guard off. Would always set the saw down sideways.

__________________

1986 300SDL, 362K 1984 300D, 138K |

|

#9

|

|||

|

|||

|

I've got a very old 3/4" drill which would twist your spine into a pretzel if you gave it half a chance. Tenant was using it to mix up some floor leveler in a 5 gallon bucket. When it got too dry, I see the tenant start spinning around and a second later the bucket is 5' in the air spinning it and the tenant in a huge circle with floor leveler spewing everywhere.

__________________

1977 300d 70k--sold 08 1985 300TD 185k+ 1984 307d 126k--sold 8/03 1985 409d 65k--sold 06 1984 300SD 315k--daughter's car 1979 300SD 122k--sold 2/11 1999 Fuso FG Expedition Camper 1993 GMC Sierra 6.5 TD 4x4 1982 Bluebird Wanderlodge CAT 3208--Sold 2/13 |

|

#10

|

|||

|

|||

|

Quote:

The gentleman doing the example with the blade stop used a method most of us use by habit. When feeding along the fence hook the index finger over the fence. On occasion things may happen that take the wood across the blade and your hand as well is a possibility. Semi anchoring it does reduce the risk. Today you should use various forms of push devices that further reduce this need. Incidentally he probably learnt the hooking of the pinky finger from a bad experience at some time but did not get any hand damage. Same as I did basically. Only a matter of good circumstance as many in the same situation did not have that. It is not a thing you should learn first hand. I mentioned in an earlier post that falling into the blade is to be avoided. I know it happens but there is no reporting of it as it is just treated as an injury. Some of the things I dwell on a little are a situation of once occurring is far too many times. You will never do it again but it is then a little late for that sentiment. Dull blades are very dangerous to work with is well worth remembering. There is almost an art form to setting up a table saw incidentally. Manufactures do not optimise them for quiet vibration free running and a few other things. There is not much you can do with the direct motor driven blade type in this area other than getting the blade perfectly parallel with the miter slot that I can think of. Still it usually was some bad habit that caused the issue. Table saws are not a device to learn their habits by personal experience. Ten fingers a day apparently get removed every day in the states by the sellers description and I can believe that. It happens because of something they have not learned usually so it is not truly an accident. That's why I feel blade stops as compulsory inclusions on new tale saws are a reasonable proposition. Sixty bucks for a new part is always going to be far cheaper than finger and hand damage and the temporary or long term effects of it. One of my daughters wanted to become as proficient as I am in power tool usage. I had to tell her that a finger or fingers loss on a male is far easier in society than it is for a woman. If they had blade stops available way back then I would have consented to that daughters wish. There is a common sense rule that cannot be totally defeated in my opinion. If you do things at some point or another you will most likely get hurt in one fashion or another. It just goes with the territory. It is the totally unexpected usually. Nobody can know everything. I may as well mention one more important thing. Never cut Styrofoam with a table saw. It is extremely dangerous. I still do a little but take excessive caution when doing so. Get a cheap carbide blade for cutting aluminum as well. Since you should always wear protective glasses the rule does not change with aluminium. Also a carbide blade on backwards does well with many plastics. Last edited by barry12345; 02-16-2015 at 03:37 PM. |

|

#11

|

||||

|

||||

|

Quote:

Is there any chance of getting a floor-stand for it - from that era that was made for it? |

|

#12

|

||||

|

||||

|

Quote:

The pedestal floor stands are incredibly rare and I need mobility so I'm building a table |

|

#13

|

|||

|

|||

|

Quote:

__________________

Paul S. 2001 E430, Bourdeaux Red, Oyster interior. 79,200 miles. 1973 280SE 4.5, 170,000 miles. 568 Signal Red, Black MB Tex. "The Red Baron". |

|

| Bookmarks |

| Thread Tools | |

| Display Modes | |

|

|