|

|

|

|

|

|

|

|

|

|

|

#1

|

||||

|

||||

|

W123 Front Shock Replacement DIY

Hello,

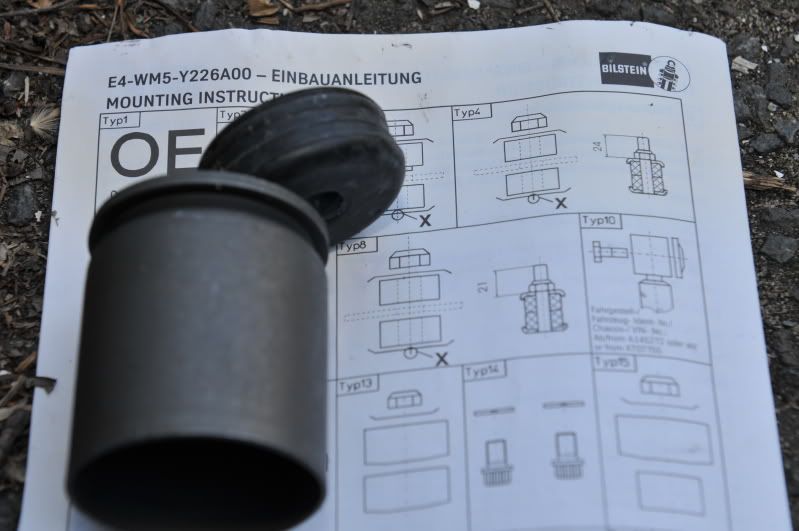

Having just done tie rods, idler arm, brake lines, oil separator seal and idler arm rebuild on my 82 300CD, I have a lot of pictures to show and DIYs to put together. The tie rod/idler one has a LOT of images, so Im going to work that one last. First one is shocks... Here it goes: My shocks at 163k still had OK bounce, but were showing some rub marks, surface rust and some leakage that I guess is lubricating oil from inside. I have front and rear shocks, so I figured I'd start working the replacements. I did the fronts this time, and will do the rears when I have the seats out for window regulator replacement. Tools Required: Plier or adjustable wrench box end wrenches (17mm), a ratcheting box-end is helpful Ratchet w/17mm socket 10mm 12 point socket 3" extension I replaced the shocks on my 83 with the wheels on the ground. I replaced the shocks on my 82 with the wheels in the air because I already had the car up. It is slightly easier to have the wheels in the air. The first thing to do is remove the locknut system that is on top of the shock rod. This could be one of two setups, either a nut with another nut locking it down, or a single locking nut. This will require either: a wrench to hold the first with a second wrench or socket to undo the top one in the case of two nuts; or else if there is just a single locknut on the shaft, then a wrench and a plier or adjustable to actually hold the shaft. In the case of two nuts, then the second nut is removed by the process mentioned with the locknut case.  My wheels were straight ahead the whole time. Some suggest that it is easier to move the wheels either way for access. I do not see the need. The next step is to remove the accessible bolts that hold the shocks to the lower control arm. These are the outboard bolts. I used a standard 12 point socket from a ratchet set.  After they are removed, get the shaft pushed down through the hole in the fender from above (I found a long 1/4" ratchet extension helped) and muscle the shock shaft down by pushing via the boot.  You can get the shaft to stay down by releasing it against the fender liner. Angle it so that the inboard 10mm bolts are accessible.  Now, the confusing part. There is at least one thread that I wrote from long ago and continued when I did these installs pertaining to how to properly set up the new boots, washers, etc. The shock is supposed to have a "type" marking on it, but mine didnt.  Key is to remove the black metal part from inside the new boot.  One of the two supplied black rubber buffers sits on the beveled washer part that makes the top of this item.  Another view:  So slide the rubber part in and then put the black metal item back into the boot. Make sure it is all seated properly. Slide this along the shaft until it bottoms at the small washer on the shaft. Installation really is the reverse of removal. Compress the shock a bit, and let it jam into the plastic liner of the fender. Align it so that the inner bolt hole is exposed first, and get it threaded in. I also hand-threaded the outer bolt just a bit by hand to make sure that everything is well-aligned. Tighten the inner bolt down first.  Then release the shaft into the hole and go ahead and tighten the second bolt.  The new shocks likely have a locknut, so the tools are the wrench and the adjustable wrench or plier. The key is to hold the small tab on the top of the shock shaft so it does not spin, and then tighten down the locknut.  I tightened it so that three threads on the shock shaft are visible.  Done!

__________________

Current Diesels: 1981 240D (73K) 1982 300CD (169k) 1985 190D (169k) 1991 350SD (113k) 1991 350SD (206k) 1991 300D (228k) 1993 300SD (291k) 1993 300D 2.5T (338k) 1996 Dodge Ram CTD (442k) 1996 Dodge Ram CTD (265k) Past Diesels: 1983 300D (228K) 1985 300D (233K) |

|

#2

|

||||

|

||||

|

IMHO even though the instructions says so, I think having the "cupped" washer with the cup side down can lead to problems later on in time in which the bushing becomes so compressed that the edge of the washer starts knocking on the body washer. I like to install it with the cup side up to prevent any of that, and works just fine.

.

__________________

1983 123.133 California - GreaseCar Veg System |

|

#3

|

||||

|

||||

|

Nice write up.

I see you used new bolts (for the LCA mount) which had the ready to go thread lock on there - for those of you who don't have new bolts don't forget that you need to glue em!

__________________

1992 W201 190E 1.8 171,000 km - Daily driver 1981 W123 300D ~ 100,000 miles / 160,000 km - project car stripped to the bone 1965 Land Rover Series 2a Station Wagon CIS recovery therapy! 1961 Volvo PV544 Bare metal rat rod-ish thing I'm here to chat about cars and to help others - I'm not here "to always be right" like an internet warrior Don't leave that there - I'll take it to bits! |

|

#4

|

||||

|

||||

|

most commercial tool trucks have the special socket that fits the end of the shock shaft. makes removal of this type of shock a breeze.

__________________

John HAUL AWAY, OR CRUSHED CARS!!! HELP ME keep the cars out of the crusher! A/C Thread "as I ride with my a/c on... I have fond memories of sweaty oily saturdays and spewing R12 into the air. THANKS for all you do! My drivers: 1987 190D 2.5Turbo 1987 190D 2.5Turbo 1987 190D 2.5-5SPEED!!!  1987 300TD 1987 300TD 1994GMC 2500 6.5Turbo truck... I had to put the ladder somewhere! |

|

#5

|

||||

|

||||

|

Dont see how it would work with the two-nut setup that was originally on there. Also dont really see the need, especially given the ratcheting type box end wrenches, which can be slipped over and the shaft held tight.

MB does have a tool that is a concentric holder with a socket of some sort. Sure didnt see the need...

__________________

Current Diesels: 1981 240D (73K) 1982 300CD (169k) 1985 190D (169k) 1991 350SD (113k) 1991 350SD (206k) 1991 300D (228k) 1993 300SD (291k) 1993 300D 2.5T (338k) 1996 Dodge Ram CTD (442k) 1996 Dodge Ram CTD (265k) Past Diesels: 1983 300D (228K) 1985 300D (233K) |

|

#6

|

||||

|

||||

|

Quote:

Or else shocks in severe need of replacement. Ive not seen such an issue on any of my w123 cars... Good tip though if folks have issues...

__________________

Current Diesels: 1981 240D (73K) 1982 300CD (169k) 1985 190D (169k) 1991 350SD (113k) 1991 350SD (206k) 1991 300D (228k) 1993 300SD (291k) 1993 300D 2.5T (338k) 1996 Dodge Ram CTD (442k) 1996 Dodge Ram CTD (265k) Past Diesels: 1983 300D (228K) 1985 300D (233K) |

|

#7

|

||||

|

||||

|

It's a nice write up. I posted both of these to the DIY request page. I'll link to it when it's in.

Thanks!

__________________

John HAUL AWAY, OR CRUSHED CARS!!! HELP ME keep the cars out of the crusher! A/C Thread "as I ride with my a/c on... I have fond memories of sweaty oily saturdays and spewing R12 into the air. THANKS for all you do! My drivers: 1987 190D 2.5Turbo 1987 190D 2.5Turbo 1987 190D 2.5-5SPEED!!!  1987 300TD 1987 300TD 1994GMC 2500 6.5Turbo truck... I had to put the ladder somewhere! |

|

#8

|

||||

|

||||

|

Thanks! A bunch more to come as I get all the pictures from two cameras sorted and then everything written up...

__________________

Current Diesels: 1981 240D (73K) 1982 300CD (169k) 1985 190D (169k) 1991 350SD (113k) 1991 350SD (206k) 1991 300D (228k) 1993 300SD (291k) 1993 300D 2.5T (338k) 1996 Dodge Ram CTD (442k) 1996 Dodge Ram CTD (265k) Past Diesels: 1983 300D (228K) 1985 300D (233K) |

|

#9

|

|||

|

|||

|

awesome write-up.

__________________

1983 300 Turbo-"Nora" 1983 240D Auto "Lucia"-slowest on earth-1st love 1985 300 Turbo-Blue Goose-slowly plucking parts http://i117.photobucket.com/albums/o...ly15/mbsig.jpg |

|

#10

|

|||

|

|||

|

How similar is the install process for a 1982 300SD 126?

|

|

#11

|

||||

|

||||

|

Iirc, the suspension is mostly the same, including the LCAs. That's why one can get w126 bushings and use them on a w123.

Better verify that for certain though... Might want to look through fastlane to see if the shocks/LCAs are the same part numbers.

__________________

Current Diesels: 1981 240D (73K) 1982 300CD (169k) 1985 190D (169k) 1991 350SD (113k) 1991 350SD (206k) 1991 300D (228k) 1993 300SD (291k) 1993 300D 2.5T (338k) 1996 Dodge Ram CTD (442k) 1996 Dodge Ram CTD (265k) Past Diesels: 1983 300D (228K) 1985 300D (233K) |

|

#12

|

||||

|

||||

|

First, nice write up. Your timing is excellent.

My Bilsteins (ordered from Fastlane of course) just arrived and I'll be tackling this once my thumb fully heals from an event that required stitches. JHZR2 (OP), you say you never had the wheels off and they were straight for this whole project? Nice pics! Did you do it by Braille? I tried to look at this with the wheels straight and I can barely see a thing. Can this be done with the wheels on and the wheels turned out for easier access, so I can see what I'm doing? The driveway is on a slight slope, so I'd rather not jack up the car if I don't have to.

__________________

85' 300D No inspection, No registration fees, Cheap insurance  "If my calculations are correct, when this baby hits 88 miles per hour, you're going to see some serious %$&^." |

|

#13

|

||||

|

||||

|

Yeah, once I did it with wheels on the ground, and this time wheels in the air (and off of the car). Of course it is much easier to do it up in the air, wheels off.

It is much harder to do it on the ground. Key is to puch hard to keep the shocks compressed so they can be finagled in...

__________________

Current Diesels: 1981 240D (73K) 1982 300CD (169k) 1985 190D (169k) 1991 350SD (113k) 1991 350SD (206k) 1991 300D (228k) 1993 300SD (291k) 1993 300D 2.5T (338k) 1996 Dodge Ram CTD (442k) 1996 Dodge Ram CTD (265k) Past Diesels: 1983 300D (228K) 1985 300D (233K) |

|

#14

|

||||

|

||||

|

PS to keep the shaft from turning you can use a 6mm wrench (not that adjustable is bad)...

__________________

http://superturbodiesel.com/images/sig.04.10.jpg 1995 E420 Schwarz 1995 E300 Weiss #1987 300D Sturmmachine #1991 300D Nearly Perfect #1994 E320 Cabriolet #1995 E320 Touring #1985 300D Sedan OBK #42 |

|

#15

|

|||

|

|||

|

Hello!

Question..... I have just purchased a w123, 230e and I would like to try and replace the front shocks myself. It would be the first time I tried doing this on any car. Is the description above THAT easy to do? As it comes across as not difficult... I tried looking at it with the wheels pointing forward, but that would be impossible for me I think. If this is a good method for a novice front shock replacer, would it be OK to do it with the front wheels pointing at an angle..? Thoughts? |

|

| Bookmarks |

|

|