If the fitting separated from the cooler end tank, I think it's time for a new oil cooler. I certainly wouldn't trust a weld at that point as a failure would almost certainly be catastrophic to the engine.

If you just broke off the threaded portion, a permanent solution is to redo the system to take AN fittings. On the cooler, drill out the hole to 3/4" and tap for 1/2NPT.

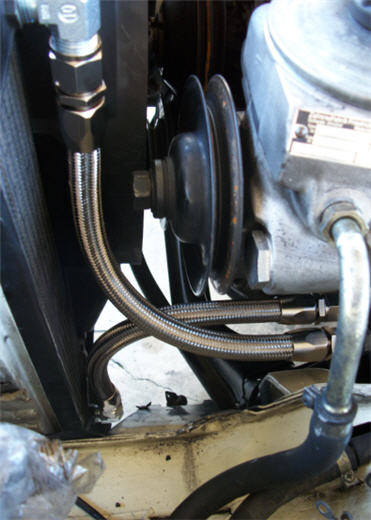

Then install -10AN to 1/2NPT 90s

You'll need to modify the cooler lines by brazing on -10 AN fittings.

Then make up your hoses and install

Now you're set. The hose fittings are reusable so if you ever have a leaky hose just make up new ones using the existing fittings.