|

|

|

|

|

|

|

|

|

|

|

#16

|

||||

|

||||

|

Me and a buddy were talking about a "combustion efficiency" display in our ideal diesel car of the future. Kind of like the way some of the new Detroit gassers display fuel efficiency - only not a hokey gimmick, but a real indicator of what goes on in each cylinder. I think your glow plug as a sensor idea is along this same line.

__________________

327K on 1986 W201, 602.911, 722.414 2.5 190D ("The Red Baron") 139K on 1993 W124, 104.942, 722.433 2.8 300E ("Queen") http://farm5.static.flickr.com/4081/...0bb92d3c_m.jpg http://i370.photobucket.com/albums/o...g?t=1325284354 Do not worry about your difficulties in Mathematics. I can assure you mine are still greater. - Albert Einstein take a walk down memory lane... |

|

#17

|

||||

|

||||

|

On airplanes often airplanes will have an Exhaust gas temprature for each cylinder so that folks building their own cooling plenums (air) can verify that all cylinders are running smoothly and equally. I beleive they just port the exhaust manifold at a uniform distance from the head with a high temp thermocouple. Sounds like a lot of work, but it would be interesting.

__________________

1990 300D 2.5 Turbo 150k miles 1999 F250 7.3L Powerstroke 225k miles 22mpg Intro Thread |

|

#18

|

|||

|

|||

|

Quote:

Your OP was and I quote: "Assuming the following: - rebuilt, calibrated original set of injectors - rebuilt head, including prechambers, valve guides, seals - non-contaminated fuel With no apparent fuel leaks, can worn delivery vales/sealing washers & rings be the cause of nailing? If so, how? " So my answer held true because you did NOT have properly calibrated injectors. Properly calibrated injectors isolate the spray formation and pattern from pump issues (except for timing...of course) due to the pop pressure being the final arbiter in the sequence. This is not about me being right or wrong (no ego tied up here! ) but I would like you to privately acknowledge that I did not mislead you

__________________

Dionysius |

|

#19

|

||||

|

||||

|

Quote:

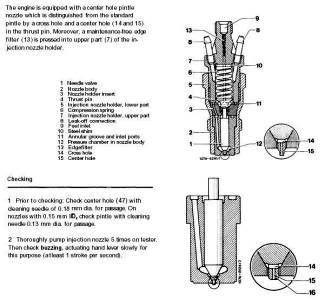

Also it is one of the least skilled jobs in a Fuel Injection shop; it may be that they were training someone or just in a hurry. The thing about shimming the Injectors is that each Spring from each Injector will not have exactly the same tension (ounce in a while they also break), the dimensions of the Injector parts that effect the pressure are also different. Hence the need to use shims to adjust the pressure. If you ever rebuild your own set keep the parts from each Injector segregated from the others; it makes them easier to shim. Your Spray Nozzle may not look like the one in the pic; used to show the relationship of the Spring #8 and shims #10.

__________________

84 300D, 82 Volvo 244Gl Diesel Last edited by whunter; 09-13-2009 at 07:30 PM. Reason: spelling |

|

#20

|

||||

|

||||

|

Quote:

__________________

84 300D, 82 Volvo 244Gl Diesel |

|

#21

|

||||

|

||||

|

Mystery solved

Quote:

Mind you this is an abridged version of a detailed story that relates a nailing problem that would surface slowly after purging air from my fuel system. I thought I had it fixed after I discovered that the injectors were not popping precisely within spec and made the shop reset them all three times. The shop was great, they were consistently nice to me, every time I went in there they gave me free goodies like return line hose, loan of special socket to remove delivery valves, and notepads/pens in addition to pop testing and calibrating my injectors for free three separate times. This shop was a great place to learn, I ran into some "old timers" (including a Stanadyne rep) and these guys felt pretty strongly that air infiltration was my problem. After many trips to the injector shop, setting the pop pressure at 120, 138, and back to 125 in succession, 5 sets of injector heat shields, countless fuel hose clamp tightening operations, replaced primary filter, many sleepless nights visualizing my fuel delivery circuit, and expecting the inevitable horror of pulling my IP, I have solved this mystery wrapped in a riddle inside an enigma. When inspecting my secondary filter I discovered that as a result of over-torquing the hollow screw to hell and back, the center rubber seal in the canister was chewed up and distorted leaving the opportunity for the return fuel to mingle with the delivery fuel (see my latest thread). While I had the secondary fuel filter housing and canister off, I replaced the three connectors that link the housing/canister to the IP (milky white translucent plastic dealer items w/banjo and compression fittings). Put it all back together and presto, nailing problem solved. Whether the problem was caused by the filter or by the IP/fuel filter connectors, I don't know but the car runs like a new one now. I wanted to let everyone know that all is well and I am ready to tackle the next problem. I have learned to slow my tortured brain down and expect the simplest solutions to be the secret to success.

__________________

327K on 1986 W201, 602.911, 722.414 2.5 190D ("The Red Baron") 139K on 1993 W124, 104.942, 722.433 2.8 300E ("Queen") http://farm5.static.flickr.com/4081/...0bb92d3c_m.jpg http://i370.photobucket.com/albums/o...g?t=1325284354 Do not worry about your difficulties in Mathematics. I can assure you mine are still greater. - Albert Einstein take a walk down memory lane... |

|

#22

|

||||

|

||||

|

LOL!

__________________

84 300D, 82 Volvo 244Gl Diesel |

|

#23

|

||||

|

||||

|

It might be nice to repeat the name of the Fuel Injection Shop you got such great service from.

__________________

84 300D, 82 Volvo 244Gl Diesel |

|

#24

|

||||

|

||||

|

Diesel Fuel Injection Service - Portland, OR

__________________

327K on 1986 W201, 602.911, 722.414 2.5 190D ("The Red Baron") 139K on 1993 W124, 104.942, 722.433 2.8 300E ("Queen") http://farm5.static.flickr.com/4081/...0bb92d3c_m.jpg http://i370.photobucket.com/albums/o...g?t=1325284354 Do not worry about your difficulties in Mathematics. I can assure you mine are still greater. - Albert Einstein take a walk down memory lane... |

|

#25

|

||||

|

||||

|

Has anyone referenced here all the possible causes of "nailing"? From what I understand, that annoying sound could be caused by (don't quote me, I'm observing, but don't really know):

-injector nozzles with poor spray pattern (dirty or worn) -injectors that are sticking/not popping correctly -air leak (where? supply lines?) -bad fuel -pump timing (too advanced? too retarded? I don't know) -weak injection pump (?) -excess carbon buildup in pre-chambers (?) I've been trying to figure out how to tackle a periodic, random nailing I'm hearing....it happens most often under light throttle...goes away under heavy throttle, and not present at warm idle. Somedays it's really bad, other days, barely at all. Diesel purge didn't help, so I'm thinking it's time to replace the injector nozzles, but now I'm wondering if that's REALLY the problem (probably won't hurt though).

__________________

1976 240D "Katja" |

|

#26

|

||||

|

||||

|

Quote:

I have not understood why yet but apparently some nailing can be caused by too advanced or too retarded IP timing. The Nailing/Knocking sound has to do with too much of the Fuel bruning at the wrong time and or place in the Pre-Combustion chamber. Burning and the wrong time and place includes most of what you said. You also left out low/bad compression. Weak Injection Pump- I am not sure what you mean by this. Worn or abused IPs have erattic fuel delivery and deliver less fuel. I am speaking of the high pressure fuel that goes to the Injectors. This can be caused by worn Elements/Plungers and Barrels (scratches on the parts due to bad fuel or poor filtration or some alternate fuels) or if the Rollers, Tappets, and Camshaft inside of the IP are worn (the makes the internal timing of the IP). [On other vehicles with Rotary type Fuel Injection Pumps (like VW Rabbits, my Volvo and vehicles with Standyne IPs) the advance mecanism is built into the Fuel Injection Pump and as the pump wears the advance become retarded over time. The advance pistons are also at the bottom of the IP and that is where any water will also settle. If the water sits long enough the advance piston can stick.] Aparrently on those IPs with O-rings that leak; when they leak it some time causes nailing (from what I have read in the threads). Quite a few members have reported that after the O-ring changing job they experienced Nailing until they have driven 200 miles or so. The reason for this has yet to be explained. I am not sure if a weak Fuel Supply pump will cause Nailing or not. I guess with the OP saying it was his filter there could be something but it is not clear to me what it is. I have not read of the excessive Carbon explination for Nailing. I would be the result of another problem or problems like Oil burning, bad Injector Nozzle, Ball Ping damaged, damaged Pre-chamber, bad fuel and so on.

__________________

84 300D, 82 Volvo 244Gl Diesel Last edited by Diesel911; 08-09-2009 at 11:43 PM. |

|

#27

|

||||

|

||||

|

When air is in the lines, the spray pattern is disrupted. In my case, I have a rebuilt head (new valve guides, seals, rebuilt injectors) and the bottom end is in good shape. When purged of air, the engine runs like a new one. Slowly, over a period of about 3 or 4 days it would begin to show the signs of air creeping back into the fuel system (nailing, rough starts) but when it runs well, it really runs well, smooth smokeless starts - no nailing whatsoever under any circumstance. That was the real clincher evidence that the problem was air. Even when the car was nailing, I could drive it real hard - 75 or 80 mph on the freeway for a couple of hours always purged it enough to run smooth for a while.

During the head refurbishment, the IP pump sat for about 3 months with the injector lines off. The PO burned B99 for a year, and I used B99 for about 4 months after first acquiring the car. All the fuel lines were 5/16" Gates and were swollen and distorted when I replaced them. The IP poly-connectors to the fuel filter housing had become brittle, but did not seem to be leaking - I replaced them anyway. The IP has no outward sign of fuel leaks. Somehow air was getting in. Many times I pondered the possibility that air was getting by the delivery valve o-rings when the car was off. Possibly negative siphon pressure was slowly pulling air into the pump. However, if that were the case, then the air would be purged after running for a bit. I would be very receptive to any input on this theory. Air infiltration is a peculiar beast. A ghost with no direct trace to its whereabouts. Whatever I did, the engine is better now - for how long will be the question where all of my (and other's) theories will be tested.

__________________

327K on 1986 W201, 602.911, 722.414 2.5 190D ("The Red Baron") 139K on 1993 W124, 104.942, 722.433 2.8 300E ("Queen") http://farm5.static.flickr.com/4081/...0bb92d3c_m.jpg http://i370.photobucket.com/albums/o...g?t=1325284354 Do not worry about your difficulties in Mathematics. I can assure you mine are still greater. - Albert Einstein take a walk down memory lane... |

|

#28

|

|||

|

|||

|

You are doing good work here Sasquat. Keep it up until it reaches a solid conclusion.

It is possible that it takes more than one cause occuring simultaneously to set up a nailing condition such as the intermittent type at low throttle. Revisit your theories with this in mind and see if you get further. If you would not mind could you please redo the list you started after you get all of the input and try to prioritize it and organize it. You might also add valve adjustment as a potential contributing cause. This nailing is an insidious condition that can do damage over a long period of time.

__________________

Dionysius |

|

#29

|

||||

|

||||

|

Of course he would need to have adjustable lifters, his 602 does not.

__________________

Gone to the dark side - Jeff |

|

#30

|

|||

|

|||

|

This is indeed true but the fact is that if the hydraulic lifters are not to specification his valve train timing will be off. This alone could cause nailing. And further if there is drift in the lifters with time and temperature the nailing will be more difficult to characterize and may not be always repeatable. This thread is now into advanced nailing issues so every possibility has to be brought up.

__________________

Dionysius |

|

| Bookmarks |

|

|