|

|

|

|

|

|

|

|

|

|

|

#1

|

|||

|

|||

|

Two questions for the 60X experts

Hi

First, I have a 601 head without the cam bearing caps. Is it possible to use caps from an other head with out line boring/honing? Also, the engine, this head was installed on, must have sad outside for a while, and 3 cylinders filled with rainwater. There was a large amount of rusty residue in the combustion chambers, and I suspect the valves and valve seats are rusted. I didn't remove the valves yet. The head is straight as measured with a straight edge. Is this head fixable, is it worth saving/fixing? I don't have any use for it. Second, A #14 603 head that is 0.25mm ,about 0.01" bend, probably over heated, and has a broken pre chamber. There is also some aluminum corrosion on the parting surface that has to be welded. What is the verdict on this one?

__________________

76 240 D. Bought in 1998 for $25. 85 300D. Got it for free with a bad engine. ( Sold ) 60 Unimog 404. What was left of it, was given to me. Now powerd by 617A. 88 560 SEL. Bought without engine and trans. Now powerd by 617A. 67 250 SE. Cuope. For resto or sale. 64 220SE. For resto. |

|

#2

|

||||

|

||||

|

Repair or replace?

FSM says that the cam bearing caps are unique to each head; replacement caps must be line-bored.

The rust problem cannot be accurately determined until the valves are removed. The valves may need to be replaced if the stems are badly rusted. Valve guides can be replaced, ditto the valve seats. However, each item adds to the cost of repair so yes, repair is possible, but it may not be practical. You may be able to find a good head for the cost of repairing this one. As to the head with the divots, I had a similar situation with my '87 300D (W124, OM603), which I discovered when I replaced the original #14 head with a #20. Both head and piston had divots similar to yours in the #2 cylinder. I never did determine the cause but left the piston as-is and the engine runs OK now with the new head. Jeremy

__________________

"Buster" in the '95 Our all-Diesel family 1996 E300D (W210) . .338,000 miles Wife's car 2005 E320 CDI . . 113,000 miles My car Santa Rosa population 176,762 (2022) Total. . . . . . . . . . . . 627,762 "Oh lord won't you buy me a Mercedes Benz." -- Janis Joplin, October 1, 1970 |

|

#3

|

||||

|

||||

|

601 = I'd lay Plastigage on the head and tower halves of the cam bearings and toss a coin based on the results.

603 = what's the cost of repair vs the cost of a good used later casting? Or a good used #14, for that matter. Sixto 87 300D |

|

#4

|

||||

|

||||

|

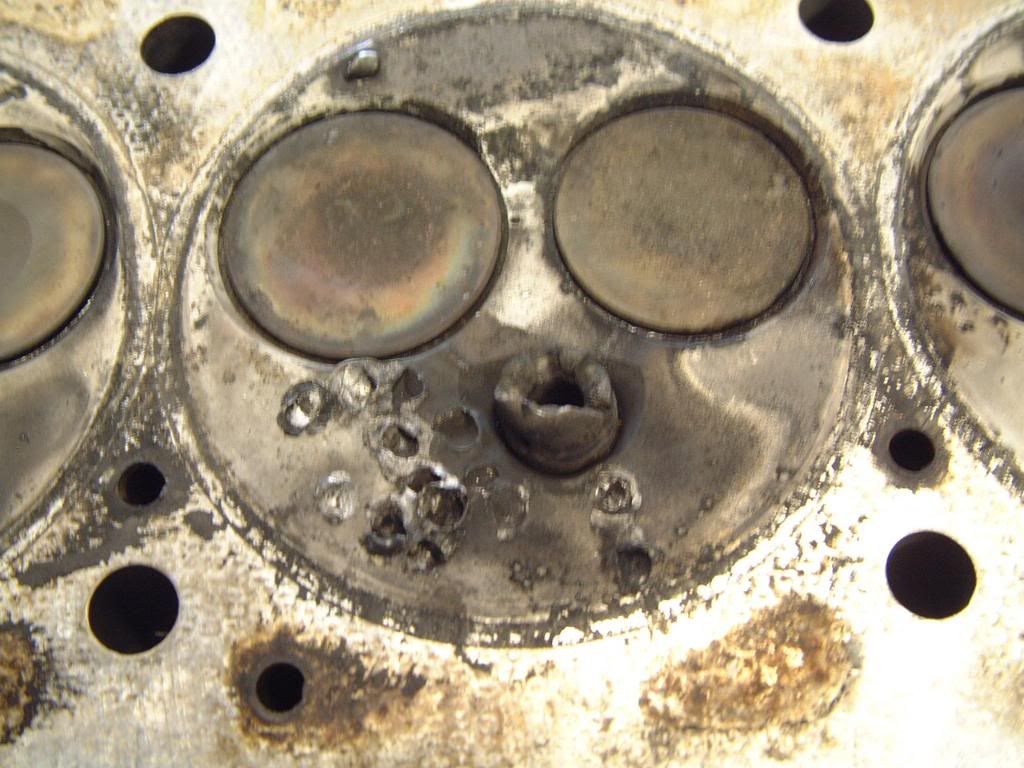

The dents are from the prechamber blowing out and dropping its heat ball into the cylinder, no? You can see the burnt open prechamber in the first photo. I'm surprised the piston didn't also get a hole burned through its crown if there was enough heat to melt the prechamber.

I've heard of 603's running fine minus one cylinder for any list of given reasons, zero compression, so... I view one pot as a "spare" half litre of displacement. Maybe a little lumpy at idle but still enough power to pass.

__________________

Cheers! Scott McPhee 1987 300D |

|

#5

|

|||

|

|||

|

Two cracks showing. One crack at each valve leading from prechamber.

Pits can be cleaned up as long as not in gasket sealing area.

BenzDiesel |

|

#6

|

||||

|

||||

|

I about threw up looking at these pictures.

__________________

Jim |

|

#7

|

|||

|

|||

|

Thanks for your replys guys.

Is it possible to straighten a 603 head that is 0.01" bend? I can machine the parting surface, but what about the cam bearings? This head is not creaked, may just be an optical illusion. The damage is from the parts that blow of the PC, I don't know about the piston. I only have the head. I can install the caps from the 603 on the 601 head and use a dial bore gauge to check the bores, but first i should check the rust on the valve seats.

__________________

76 240 D. Bought in 1998 for $25. 85 300D. Got it for free with a bad engine. ( Sold ) 60 Unimog 404. What was left of it, was given to me. Now powerd by 617A. 88 560 SEL. Bought without engine and trans. Now powerd by 617A. 67 250 SE. Cuope. For resto or sale. 64 220SE. For resto. |

|

#8

|

||||

|

||||

|

There is a spec for how much the prechamber tip can protrude into the combustion chamber. You might have to shim the prechamber if you cut more than so much of the head. I suppose there's a height spec for valve stems as well.

Sixto 87 300D |

|

#9

|

|||

|

|||

|

Well, the problem is the cam shaft.

The head is not only bend at the parting surface, but also at the cam bearings. What happen to a straight cam, when i tight it down on to a banana shaped head?

__________________

76 240 D. Bought in 1998 for $25. 85 300D. Got it for free with a bad engine. ( Sold ) 60 Unimog 404. What was left of it, was given to me. Now powerd by 617A. 88 560 SEL. Bought without engine and trans. Now powerd by 617A. 67 250 SE. Cuope. For resto or sale. 64 220SE. For resto. |

|

#10

|

||||

|

||||

|

__________________

327K on 1986 W201, 602.911, 722.414 2.5 190D ("The Red Baron") 139K on 1993 W124, 104.942, 722.433 2.8 300E ("Queen") http://farm5.static.flickr.com/4081/...0bb92d3c_m.jpg http://i370.photobucket.com/albums/o...g?t=1325284354 Do not worry about your difficulties in Mathematics. I can assure you mine are still greater. - Albert Einstein take a walk down memory lane... |

|

#11

|

||||

|

||||

|

The words don't make sense to me but this might be relevant to your query -

Quote:

Sixto 87 300D |

|

#12

|

||||

|

||||

|

Specs

Quote:

The permissible unevenness of the mating surface is 0.08mm longitudinally and 0.0mm transversely. The maximum permissible roughness is 0.004mm. The maximum that the top and bottom head surfaces may be out of parallel is 0.1mm in the longitudinal direction. Your head does not sound like it can be salvaged. Jeremy

__________________

"Buster" in the '95 Our all-Diesel family 1996 E300D (W210) . .338,000 miles Wife's car 2005 E320 CDI . . 113,000 miles My car Santa Rosa population 176,762 (2022) Total. . . . . . . . . . . . 627,762 "Oh lord won't you buy me a Mercedes Benz." -- Janis Joplin, October 1, 1970 |

|

#13

|

||||

|

||||

|

As previously stated If you replaced the Cam Bearing Caps the Camshaft bore would need to be line bored.

The question is where would you get the Bearings to fit it after the line boring? How, much line boring would it take to straighten out the Camshaft bore; and would that be too much for the Bearings if they are even available?

__________________

84 300D, 82 Volvo 244Gl Diesel |

|

#14

|

||||

|

||||

|

So the raw surface after line boring isn't an appropriate bearing surface as with a good head?

Sixto 87 300D |

|

#15

|

|||

|

|||

|

Quote:

I never have seen bearings in this heads of any size.

__________________

76 240 D. Bought in 1998 for $25. 85 300D. Got it for free with a bad engine. ( Sold ) 60 Unimog 404. What was left of it, was given to me. Now powerd by 617A. 88 560 SEL. Bought without engine and trans. Now powerd by 617A. 67 250 SE. Cuope. For resto or sale. 64 220SE. For resto. |

|

| Bookmarks |

|

|