|

|

|

|

|

|

|

|

|

|

|

#1

|

|||

|

|||

|

722.3 Transmission leak fail

The transmission is from a 1983 W123-300TDT (USA version).

After replacing the bearing of the pump, see here: http://www.peachparts.com/shopforum/diesel-discussion/311580-722-3-transmission-pump-bearing-damaged.html I proceeded with the assembly of the oil pump. I pressed in the seal. The seal was bought from MB:   I used two pieces of wood and a vice to press it in. I also replaced all the seals of the oil pump and put in a new gasket for the oil pump housing. Installed the torque converter, with the aid of these two metal strips, it installed correctly, the transmission was held upright during installation.  Installed the transmission, filled it with 4 liters of ATF and started the engine. No funny sounds. Put in another 2 liters of ATF and I tested the transmission. There was power to the wheels, but unfortunately there was also a large puddle of ATF on the floor, coming out of torque converter housing. There wasn't time yesterday to remove the transmission and inspect, we have to do that tomorrow, but I would like to know what the possible causes are before starting the work. And I like to know what I did wrong, so I will not do it again. The amount of oil suggests to me that it is pumped out, so there is probably a problem with the front seal. Did I install it incorrectly? Maybe the flat piece of wood made the seal "flat" too and maybe a large socket should have been used. The FSM has no special instructions or tools for pressing in the ring. Could it have been damaged during installation of the torque converter? The seal seemed sturdy enough and the torque converter went in smoothly. Any ideas? Last edited by Govert; 01-22-2012 at 06:54 AM. |

|

#2

|

||||

|

||||

|

You did put the torque converter drain plug back in didn't you? (Sorry for the smart arse comment - just checking!)

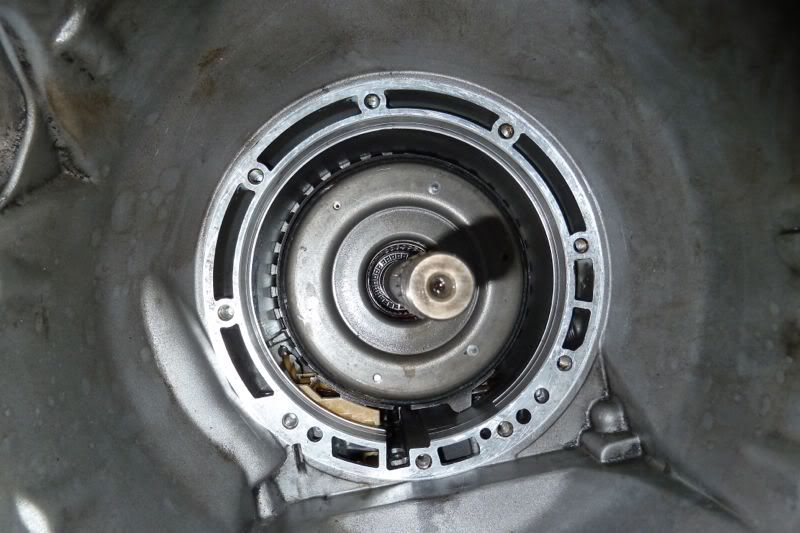

The picture "I need" is the one showing the front pump fitted with seal in place - no torque converter... If there is a gap between seal and torque converter then it will leak - do you remember it being a bit tight when you slid the torque converter into position? Nightmare - good luck.

__________________

1992 W201 190E 1.8 171,000 km - Daily driver 1981 W123 300D ~ 100,000 miles / 160,000 km - project car stripped to the bone 1965 Land Rover Series 2a Station Wagon CIS recovery therapy! 1961 Volvo PV544 Bare metal rat rod-ish thing I'm here to chat about cars and to help others - I'm not here "to always be right" like an internet warrior Don't leave that there - I'll take it to bits! |

|

#3

|

|||

|

|||

|

Here is the picture:

It did feel a bit tighter when the torque converter was properly seated, but that can also be because the oil pump was actuated. How deep must the seal be? Slightly sticking out of the pump house? or flat? I'm entertaining the possibility that the oil pump isn't original, because there was no gasket between oil pump housing and transmission. I cannot imagine MB forgetting a gasket, so a previous owner of the transmission must have had the oil pump out. The number on the pump is 1262770320, but the EPC doesn't know that number. If the oil pump isn't original, the original seal ring might not work. I think we might have to go back to Autrans, the automatic gearbox workshop and let them press in a seal. |

|

#4

|

||||

|

||||

|

When I fitted my front seal to my 722.1 I made sure that the seal was the correct one by trial fitting it to the torque converter...

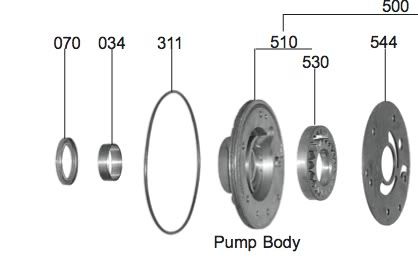

...as there were several seals in my reseal kit. As you can't check that now - how about measuring the diamter of the torque converter and the diameter of the seal fitted to the pump? I guess (and ONLY guess) that the front seal is about 1 to 2 mm narrower than the torque converter - there's a bit of flex in the lip of the seal. As for the front pump. Did you line up the input and output parts of the pump correctly? Did you fit a large rubber O ring to the outside of the pump? Part 311 as shown in the picture you posted in your other thread  How did that one feel when it went on? How did the pump feel when you fitted it? Did you need to shove it in there really hard? (Step into my parlour said the spider to the fly!)

__________________

1992 W201 190E 1.8 171,000 km - Daily driver 1981 W123 300D ~ 100,000 miles / 160,000 km - project car stripped to the bone 1965 Land Rover Series 2a Station Wagon CIS recovery therapy! 1961 Volvo PV544 Bare metal rat rod-ish thing I'm here to chat about cars and to help others - I'm not here "to always be right" like an internet warrior Don't leave that there - I'll take it to bits! |

|

#5

|

||||

|

||||

|

PS you don't need autrans - you have brains of your own.

I'm guessing the dealer cocked it up... ...was there a reason why you went to the dealer and not get a seal from autrans? Was the dealer cheaper?

__________________

1992 W201 190E 1.8 171,000 km - Daily driver 1981 W123 300D ~ 100,000 miles / 160,000 km - project car stripped to the bone 1965 Land Rover Series 2a Station Wagon CIS recovery therapy! 1961 Volvo PV544 Bare metal rat rod-ish thing I'm here to chat about cars and to help others - I'm not here "to always be right" like an internet warrior Don't leave that there - I'll take it to bits! |

|

#6

|

||||

|

||||

|

Govert - I forgot to say if you're unsure about the front pump being the right front pump I do have a 722.3 (either a .303 or a .315) in my garage that I can check for numbers if you wish.

__________________

1992 W201 190E 1.8 171,000 km - Daily driver 1981 W123 300D ~ 100,000 miles / 160,000 km - project car stripped to the bone 1965 Land Rover Series 2a Station Wagon CIS recovery therapy! 1961 Volvo PV544 Bare metal rat rod-ish thing I'm here to chat about cars and to help others - I'm not here "to always be right" like an internet warrior Don't leave that there - I'll take it to bits! |

|

#7

|

|||

|

|||

|

I do remember tightening the drain plug of the torque converter (14 Nm), but it could be that I'm becoming potty, so I'll check that again.

I did not check whether the seal ring fitted snugly over the torque converter shaft, unconsciously thinking that the ring was a MB part, so it must fit. The number of the seal ring comes from the EPC and that part was ordered. Unless they put the wrong seal in the bag, I don't see how that could go wrong. I followed the FSM when I put the pump back together, so I think I did that correctly. The rubber ring #311 was indeed changed. I had to press to put the pump body in the pump housing. I think we need another seal ring and if Autrans has that on stock, they can press it in at the same time, and they can check whether the seal ring is ok. We only have to take our torque converter and oil pump to Autrans. If I order the seal ring at the dealer, I might get the same leaking transmission. The dealer wasn't expensive for the seals. The oil pump for the 722.315 is used on nearly all the 722.3 transmissions and a couple of 722.5 transmissions as well. I'd be interested to see which number is on your oil pump. |

|

#8

|

||||

|

||||

|

Quote:

Quote:

__________________

1992 W201 190E 1.8 171,000 km - Daily driver 1981 W123 300D ~ 100,000 miles / 160,000 km - project car stripped to the bone 1965 Land Rover Series 2a Station Wagon CIS recovery therapy! 1961 Volvo PV544 Bare metal rat rod-ish thing I'm here to chat about cars and to help others - I'm not here "to always be right" like an internet warrior Don't leave that there - I'll take it to bits! |

|

#9

|

|||

|

|||

|

Problem solved – I hope.

We pulled the transmission today, went a lot faster that the first time. It was not easy to where it had leaked exactly, but it looked like the seal. We took the oil pump apart and we took oil pump and transmission to the automatic workshop company called Autrans. There they saw that there was a gasket between oil pump housing and transmission. Hm, not very smart, I should have known better, it was not the first time that I saw a gasket fused to a surface. So the oil pump was installed with two gaskets. That in itself would not have created a big oil mess, but I think I installed the new gasket incorrectly. The holes for the bolts lined up, but probably not the holes for the oil. That would have forced the oil out between the gaskets. Anyway, I spent today removing the old gasket, here is the result:  The new gasket was installed correctly and the oil pump was installed:  I put in a new seal, with a slightly shortened spring, for a better fit. Thanks all for the suggestions. |

|

#10

|

|||

|

|||

|

Ah yes, I remember that paper gasket. We didn't think of that. Yes, you are right, the real problem was the restriction of the oil holes. I don't think the double gasket would have mattered much, if at all.

__________________

80 300SD (129k mi) 82 240D stick (193k mi)77 240D auto - stick to be (153k mi) 85 380SL (145k mi) 89 BMW 535i 82 Diesel Rabbit Pickup (374k mi) 91 Jetta IDI Diesel (155k mi) 81 VW Rabbit Convertible Diesel 70 Triumph Spitfire Mk III (63kmi)66 Triumph TR4a IRS (90k mi)67 Ford F-100 (??) |

|

| Bookmarks |

|

|