|

|

|

|

|

|

|

|

|

|

|

#1

|

|||

|

|||

|

W115 240D | Injection Pump R&R | Not starting

Hi Everyone-

I removed and reinstalled my injection pump on my '74 240D and now it's not starting. I would greatly appreciate any advice/ideas. Here's the sordid story: I drip timed the injection pump 18 months ago to 24 degrees BTDC and it was running perfectly until I moved up to 8800' here in Colorado. The car was nailing pretty hard. I changed to the Bosio injector nozzles, but that didn't help. Being short on time, I loosened the injection pump and retarded (away from block) it as much as I could in the adjustment range. This cured the nailing, but it ran a little rough on cold start (it always fired right up, but smoked.) I've been driving it as is, but it started to give me the same symptoms as when the diaphragm was torn (hesitating at part throttle downhill and sudden big puffs of smoke). I had some time this holiday weekend and pulled the pump to investigate. I found that the pneumatic throttle on the back wasn't holding a vacuum. I traced the leak to the O-rings on the pneumatic throttle shaft. I replaced them, put everything back together, successfully drip timed it to 24 degrees BTDC, and went to start it--nothing. I took it all down again today and rechecked it. Based on the pump's position when I originally pulled it, the timing was probably around 19-20 degrees. I checked everything on the pump, put it back in again, timed it to 24 and it's still not starting. I did notice an odd thing, though--the number 1 injector did not have fuel welled up at the top when I pulled the injection line. The other three did. When I bled the air out, I noticed that I didn't get fuel coming out of the line like I did on the others. Is the pump bad? Did I do something wrong with the delivery valve? Why would it run well (considering the O-ring leak) at retarded timing, but not even start at 24? Could the little arm in the pneumatic throttle shaft that holds the diaphragm back for a smooth idle be causing this? Thanks! |

|

#2

|

||||

|

||||

|

Remove the Delivery Valve and Check it.

I have placed the Delivery Valve Spring on top of the Delivery Valve and some how by the time I got the Delivery Valve Holder on the Sring Fell off. Also the Deliver Valve is an assembly of 2 parts. The Center Valve only fitted and lapped into one end of the outer Cylindrical part. The Valve will go into both ends but only one is actuall machined for it. These threads sometimes puzzle Me. I have removed Fuel Injection Pumps from the Calibrating Machine and drained as much of the Calibration Oil out as I can and ever inverted the Pump to draing the Oil out of the Delivery Valve Holders. And have see Customers rotate the IP Camshaft and get spurted in the Face by the left over Oil in the Pumps. The only thing I can think of is that if you have an M type pump that you need to have a splined socket for to remove the Delivery valve when you mess the Delivery Valve Assembley (pull up on it) or if you rotate the Fuel Injection pump alot without the Delivery Valve Holder and at least the outer cylindrical Delivery Valve body the Element Plunger can rise up out of the alighment slot an Rotate. Torquing it back together like that can sometimes dmage the IP. but I suppose it could also be a Air Pocket in the #1 Area. But, you sound like you have done this work enough I expect that you are going to get it started.

__________________

84 300D, 82 Volvo 244Gl Diesel |

|

#3

|

|||

|

|||

|

Thanks Diesel911. I'll check out the delivery valve again. When I had the pump on the bench, I turned it upside down to drain out all of the old oil (seemed like a good idea at the time) before refilling with fresh oil. I hadn't yet swapped on the drip tube, but it did go through some acrobatics with the drip tube on it when I put it back in for timing.

Will it be easy enough to tell if something went wonky? |

|

#4

|

|||

|

|||

|

The M pumps on the W115 don't have the splined delivery valve holders, normal hexagon will do.

You did replace the copper ring every time after you timed the IP? And you did use the proper torque (30 Nm > Loosen > 30 Nm > Loosen > 35 Nm)? Living at 8800 ft is not good for the diesel either, I remember my 200D ran funny above about 8200 ft (in the Alps). For the 220D and 200D there was a special IP for use above 6500 ft, but the EPC doesn't list one for the 240D. It should mainly effect driving at full load. The gallery of the IP needs to be bleeded by means of the bleed screw, red arrow in the picture below:  The arm which controls the poppet cam can have something to do with it, but it acts on the general running of the engine at idle. It cannot prevent starting, but if the arm of poppet cam is maladjusted, it can prevent idling. |

|

#5

|

|||

|

|||

|

Govert, thank you for the info--this is very helpful. I'll try to bleed the gallery. Do I need to loosen or remove the screw? Then, I just prime with the hand pump?

I did not replace the copper washer in the delivery valve--I'll try that as well. I didn't know the torque procedure either. This is for the 19mm delivery valve top? I'll try that too. Thanks for the help and the picture. |

|

#6

|

|||

|

|||

|

The bleed screw only needs to be loosened. Pump with the hand pump until fuel without air comes out, close screw, pump more until you hear the pressure relief valve of the return line opening (wizzing sound).

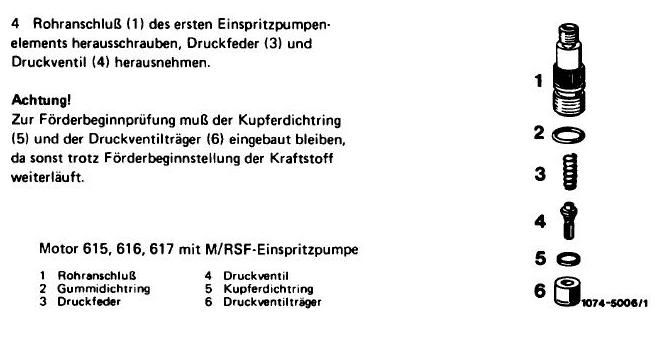

The copper crush washer is a special washer, specific to this pump. You can buy it at the dealer or at a (Bosch) diesel workshop. The torqueing procedure is to set the crush washer. Around the delivery valve holder there is a rubber O ring, that needs to be replaced if it is damaged. Rubber O ring is #2, goes around #1. Crush washer is #5. The valve holder #6 needs to be installed with the groove downwards.

|

|

#7

|

||||

|

||||

|

Quote:

Remove the Fuel Injection Hard Lines and put a straight edge acrossed the top of the Delivery Valve holders. They all should be at the same height.

__________________

84 300D, 82 Volvo 244Gl Diesel |

|

#8

|

|||

|

|||

|

Govert / Diesel911 thank you both for taking the time to share your expertise. Govert, the illustrations were particularly helpful. She is running again!

I took apart the #1 delivery valve and put it back together again with a new crush washer and the proper torque procedure. I bled the gallery with the bleed screw--no air. I still wasn't getting any fuel from the #1 line at the injector. Next, I took apart both the #1 and #2 delivery valves and swapped them. With the valve assemblies out, I primed the pump a bit to fill both holes with fuel. The #1 assembly was dry and I noticed the little nozzle valve? (#4 in the illustration) was sticking a bit in the valve holder. I lubed them both up with diesel before installing. I wanted to see if the problem stayed with #1 or moved to #2. New washers in both and used the torque procedure. I left the lines loose at the injectors and cranked. I got fuel to both. Snugged down the lines, gave a little glow and she fired right up. Thank you!

|

|

| Bookmarks |

| Thread Tools | |

| Display Modes | |

|

|