|

|

|

|

|

|

|

|

|

|

|

#1

|

|||

|

|||

|

Oil cooler nipple fitting weld

Broke off the oil cooler nipple on the lower end. Got the IP pump and filter housing out to replace gaskets, doing the leaky oil cooler lines as well. I've read a little bit about people retapping the oil cooler threads. When the whole nipple breaks off behind the hex nut, can you just reweld? I know its aluminum, but I don't see why a quality aluminum welder couldn't do it and make it work well. Please convince me otherwise, because I'm leaning this way. Unless anyone has a used cooler they are wanting to sell for a reasonable price.

__________________

1983 300CDT -- 177K Last edited by npretnar; 01-26-2013 at 09:55 PM. |

|

#2

|

||||

|

||||

|

Quote:

It used to be that a Use Oil Cooler on eBay for My 84 300D was $120-$150 each+ whatever the shipping was. A used Oil Cooler you pull from the Junk Yard was about $50 out here in My area in CA. If you Pay someone can be found to weld It would end up being close to the eBay Used Oil Cooler Price. The other problem is what do you plan to weld back onto it? Form someone else reading this thread be sure to use a wrench on the Hex that is on the Oil Cooler. In the below threads there is a method of cutting a through the Oil Cooler Hose Nut and splitting the Nut so that you do not have a chance to strip the threads off of the Nipple or rip the whole nipple off of the Oil Cooler. Repair Links http://www.peachparts.com/shopforum/forumdisplay.php?f=82 http://www.peachparts.com/Wikka/DoItYourSelf

__________________

84 300D, 82 Volvo 244Gl Diesel |

|

#3

|

||||

|

||||

|

Besides what I eMailed there is also a Used Oil Cooler on ebay for $69 or make offer.

With the Nipple repair you cut off the Threade portion of the Nipple leaving the Hex on the Oil Cooler Housing. You drill and Tap the Housing for the type of Male Hose Fittings the screw into the Oil Filter Housing. A Picture of the ripped off portion would be helpful. If a Welder could build up enough Metal you could tap and drill for the Male Hose Fitting. Again info is in the DIY Threads.

__________________

84 300D, 82 Volvo 244Gl Diesel |

|

#4

|

|||

|

|||

|

Yeah, I used two wrenches 末 one on the hex, one on the compression nut 末but the wrench I had on the line nut was way bigger and longer, and I just over-torqued it. Of course, the whole time, I was wondering why the cooler line was bending toward me 末 ripping off gradually. That + 3 days of Liquidwrench and nothing. Looks like I'm in the market for another oil cooler, preferably one whose threads have been retapped.

__________________

1983 300CDT -- 177K |

|

#5

|

|||

|

|||

|

For others reading this I was able to get mine off by soaking the fittings in PB Blaster daily for a week before I replaced the lines and had no issues.

For the OP's problem I would try to get a known good second hand cooler since I wouldn't want to risk having a weld fail in such a critical spot i.e. if it fails and you don't know immediately you need to find a new motor. |

|

#6

|

||||

|

||||

|

If the fitting separated from the cooler end tank, I think it's time for a new oil cooler. I certainly wouldn't trust a weld at that point as a failure would almost certainly be catastrophic to the engine.

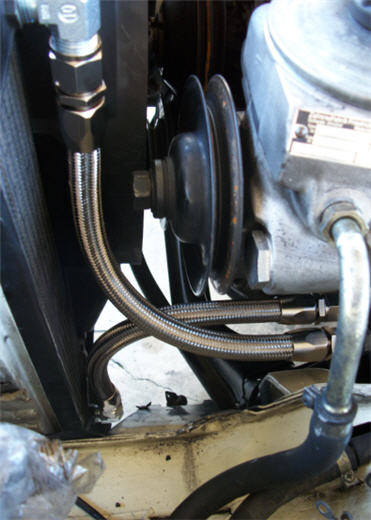

If you just broke off the threaded portion, a permanent solution is to redo the system to take AN fittings. On the cooler, drill out the hole to 3/4" and tap for 1/2NPT.   Then install -10AN to 1/2NPT 90s  You'll need to modify the cooler lines by brazing on -10 AN fittings.  Then make up your hoses and install  Now you're set. The hose fittings are reusable so if you ever have a leaky hose just make up new ones using the existing fittings.

__________________

Current Stable

|

|

#7

|

||||

|

||||

|

Quote:

The Nipple threads only need to be in good enough condition to pull the Nipple in firmly. The way it seals is similar to how thr Fuel Injection Hard Lines seal on the Injectors. What happened on one of mine is that a piece of the Aluminum Nipple thread got corroded to the Steel Hose Nut. When I turned the Hose Nut the piece of thread stuck in it acted like a cuter and took out the first 3 threads on the Nipple. I think I did the same thing you did as I had bought a large combination Wrench; while using it I had a lot of leverage and I did not feel the Threads being buggered up as I was turning it off.

__________________

84 300D, 82 Volvo 244Gl Diesel |

|

#8

|

||||

|

||||

|

I really like that repair mach4. I will have to get the tools for that repair seeing as how used MB parts are only going to get exponentially rarer. So how do the threads on the cooler seal reliably?

__________________

|

|

#9

|

||||

|

||||

|

Quote:

One important tip is, when you driil out the cooler to 3/4", use a step drill not a twist drill.

__________________

Current Stable

|

|

#10

|

|||

|

|||

|

Add a dab of Anti-Seiz compound to the threads before screwing on the MB lines.

I made lines similar to Mach4. I cut the crimps off the metal end at the Cooler, and then had AN fittings welded on, and had AN fitting welded onto the pipe ends like Mach4 shows. I used Parker Push-Loc hoses. I like the way Mach4 did his Oil Cooler end better than the way I did it, but both work the same. His has a much cleaner look than mine with the curved pipe. Charlie

__________________

there were three HP ratings on the OM616... 1) Not much power 2) Even less power 3) Not nearly enough power!! 240D w/auto Anyone that thinks a 240D is slow drives too fast. 80 240D Naturally Exasperated, 4-Spd 388k DD 150mph spedo 3:58 Diff We are advised to NOT judge ALL Muslims by the actions of a few lunatics, but we are encouraged to judge ALL gun owners by the actions of a few lunatics. Funny how that works |

|

#11

|

||||

|

||||

|

Quote:

I don't think this is a solution for the OP since I thought he broke off the threads on the oil cooler fitting. There is also the MB repair solution where you drill out the fitting and tap it for a replacement metric fitting like the original.

__________________

Current Stable

|

|

#12

|

|||

|

|||

|

Looks just like my pipe.

Here is a link to the Screwed Nipples repair. http://www.peachparts.com/shopforum/2743295-post2.html We are getting off base here from the problem the OP has. I was looking for a thread where I saw a picture of one that got tore off. can`t find it with the way the search is now. An Oil Cooler from PNP is about $20, and the time to pull it and drive down there and back. for me the closest one is 50 miles round trip, so $50 or $60 really isn`t unreasonable for a used one. I would just replace the cooler instead of welding it. Charlie

__________________

there were three HP ratings on the OM616... 1) Not much power 2) Even less power 3) Not nearly enough power!! 240D w/auto Anyone that thinks a 240D is slow drives too fast. 80 240D Naturally Exasperated, 4-Spd 388k DD 150mph spedo 3:58 Diff We are advised to NOT judge ALL Muslims by the actions of a few lunatics, but we are encouraged to judge ALL gun owners by the actions of a few lunatics. Funny how that works |

|

#13

|

|||

|

|||

|

That looks like a great mod Mach 4 because it takes the rubber hose out of the equation as well.

__________________

1983 300CDT -- 177K |

|

#14

|

|||

|

|||

|

It is still a rubber hose, just has steel braid over it.

The best part about this modification is, you never have to remove the fittings from the Cooler, and the Hoses are easier to remove. Charlie

__________________

there were three HP ratings on the OM616... 1) Not much power 2) Even less power 3) Not nearly enough power!! 240D w/auto Anyone that thinks a 240D is slow drives too fast. 80 240D Naturally Exasperated, 4-Spd 388k DD 150mph spedo 3:58 Diff We are advised to NOT judge ALL Muslims by the actions of a few lunatics, but we are encouraged to judge ALL gun owners by the actions of a few lunatics. Funny how that works |

|

| Bookmarks |

|

|