|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

LinkBack | Thread Tools | Display Modes |

|

#1

|

||||

|

||||

|

This is my off week from GA Tech, I start back next week. My brother Thomas and I are getting degrees in mechanical engineering and my friend Zach is getting his certification to become a mechanic so we are doing what we do best: fix cars.

YESTERDAY: Yesterday (Sunday) we started by heading to the parts yard and grabbing some bolts for the updated fan and clutch for my Sportline (larger fan from the E320) because the old fan clutch uses studs, not bolts. We also grabbed some massively thick 4 gauge ground and alternator cables from an Acura and a Saab as well as braided ground straps from some Saturn SLs. These are for my brother's 300SD because 1) the battery grounds on the W116 and W123 suck and 2) we bought a 150 amp alternator for his car to run an electric fan and eventually a sound system upgrade. Came out to $9.24. Last night we took the old pulley off the alternator and found that the key for the alternator shaft was different between the new alternator and the old one. The new one did not come with a key so we are searching for a key so that can be installed. TODAY: Today, Monday, we got the fan installed on the 300SD. It's a Volvo fan and fits in there very well. No bracket to mount it, it is mounted with the original holes that held the original shroud. We have a Mercedes fan from a W203 that is more powerful but it would have required a custom controller and we didn't want to deal with that.    It fits very nicely and moves a lot of air. We are going to have to have a shop modify on of the extra bungs on the engine or braze in a fitting on the radiator so we can fit the BMW temperature sensor to run it. It is much quieter than the clutch fan was and the total cost of this conversion will come out to be about as much as a new fan clutch (the one on there was going bad, Behr one is $250 now). It was $9.24 for the cables, around $35 for the fan and fan relay, and $170 for the alternator and shouldn't be too much for the work at the machine shop. Other benefit of this conversion is better regulation of AC temps and less weight on the water pump bearing. The water pump can be changed in the future without removing the fan Thomas and Zach also changed the old rotting transmission cooler lines on the 300SD. I went to work on the Sportline, first removing the bumper and draining the radiator. I then removed the charcoal canister and had my brother go out and buy new hose and clamps for it, it had been leaking and the smell was terrible. I then removed the radiator, old fan and fan clutch, fan pulley, idler pulley, power steering pump pulley, and water pump pulley so I could replace the tensioner. I had changed the tensioner adjustment lever last time I worked on the car because the threads were stripped but the tensioner was also bad and I didn't have one to replace it. But as I pulled the tensioner out, I noticed that the tensioner adjustment lever I had installed last time had stripped threads. I tried to tap and die the threads but my cheapie Harbor Freight tap and die set just damaged the threads more (I do not recommend their set). Fortunately the adjustment lever on my 190E parts car was good so I used it. I got the tensioner back in and all of the pulleys back on and routed to belt but realized I must have put the adjustment lever on backwards so I stopped working on that for the night. I was glad I ordered a new idler pulley because I wasn't sure I wanted to spend the money but when I pulley the old idler pulley off I saw that the seal on the bearing had gone and the grease had gone everywhere. Meanwhile, Thomas and Zach rigged up a cooling system, battery, and fuel tank to test a OM617 that they found at the parts yard last month. It was from a 85 300SD that apparently had around 320,000 miles but the engine looked to be in really good shape and the turbo had zero play in it. My brother bought it and the transmission for around $300 and then gifted the engine to my friend because he has always wanted to OM617 swap a truck and he has done a ton of work on our cars for us. The engine was still mated to the transmission and they were still attached to the engine hoist and set down on an old tire. Thomas used jumper cables to send power to the glow plugs and Zach jumped the starter and starter solenoid. It took some cranking but the engine came to life and smoked like hell for a few minutes then the smoke cleared. I'll put a video up as soon as Zach sends it to me but it idled and ran very well, especially considering it had been sitting for at least a few months. TOMORROW: Tomorrow (Tuesday), I plan to have the Sportline running. We are going to have to change the engine mounts on it which will entail pulling the engine from my 190E parts car because the engine mounts on it are still in good shape. I have to also replace the spark plug wires, flush coolant, and change the oil. Pulling the engine from the parts car also serves another purpose. I am selling the transmission from it to a guy I met on Craiglist. He was selling his pristine 300E 2.6 because the transmission was bad but seemed to really want to keep the car so I showed up at his house, gave the car a good look over then told him I wasn't going to buy his car and asked him if he would be interested in buying a replacement transmission. He enthusiastically said yes so I got his email and emailed him a list of the parts he needs for the transmission plus what other parts I saw on the car that needed replacing. He is a veteran of the film industry and my minor is in music technology which is in high demand in the film industry so he has been a great person to connect to. We hope to find a key for the alternator for the 300SD, I believe that they key in the alternator on my parts car is the correct size so we'll try that first before trying to find and buy one locally. The other thing we are doing tomorrow is pulling the electric motor and transaxle from a Nissan Leaf. A student at Tech bought a wrecked leaf for its battery pack for his electric converted truck and is selling off the other bits on eBay. He put the motor and transaxle up on the GA Tech classifieds for $150 because he didn't want to have to deal with shipping it and wanted another Tech student to make use of it. It is a watercooled 110 HP, 80kw three phase AC motor. We are not sure what we are going to use it in yet but there will be a plug-in hybrid project as some point in the future unless we decide to sell it. Current idea is a plug in hybrid using a small VW diesel or similarly efficient small engine as the generator, Chevy Volt style. Other stuff we gotta do this week is installing ROLLGUYS' Sanden kit on Thomas' 300SD, just have to get hoses made and the system evacuated. Both the 300SD and Sportline need new shifter bushings so those are going in and the valve cover gasket on the 300SD is going to be replaced and the engine bay cleaned up. I also have to take the Sportline in to an exhaust shop to have the catalytic converter and some of the exhaust bits replaced.

__________________

Current: 1975 450SEL, 83 300D, 88 Yugo GVX, 90 300D OM603 swap, 91 F150 4.6 4v swap, 93 190E Sportline LE 3.0L M104 swap, 93 190E Sportline LE Megasquirt, 03 Sprinter, 06 E500 4Matic wagon. |

|

#2

|

|||

|

|||

|

I have some cars you can come work on. Also a cabin in the woods about 20 mi away you could use for housing.

__________________

85SD 240K & stopped counting painted, putting bac together. 84SD 180,000. sold to a neighbor and member here but I forget his handle. The 84 is much improved from when I had it. 85TD beginning to repair to DD status. Lots of stuff to do. |

|

#3

|

||||

|

||||

|

Well I wasn't able to come back and update because I was so busy this past week. I'll start posting some of the stuff we did.

Here's the video of the start up of the OM617 we got at Pull-A-Part. Started it on the engine lift with it resting on an old tire: https://www.youtube.com/watch?v=zoXSNyU_sxM TUESDAY: The day of pulling two drivetrains and M103 tensioners Tuesday was a long day. First, we went over to a Georgia Tech CS professor's house and pulled the electric motor out of a totaled Nissan Leaf that he bought for that batteries to put into his electric truck. He had already pulled the charger and inverter but pulling the motor was very easy. Those Leafs are very nicely engineered cars. I don't have any pictures me wrenching on it but a couple of it out. We are going to go back later to grab the CV axles. It's most likely that we'll sell the motor and CV axles or donate it to the GA Tech hybrid racing team. We want to do an electric or a hybrid build at some point but it is much better to start with everything vs just the motor. We paid $150 for the motor and will pay $20 for the CV axles.   Loading it into the van. The van is set up for transporting my sister who is in a wheelchair, we use a ramp and a winch attached to the back of the driver's seat to pull her and other things such as a riding lawn mower up into the van. The system was designed by my dad and his brother who is an engineer.  All strapped down. After we got this my dad told me that he is planning to buy a Tesla Model S in the next couple of years so the electric project may or may not happen. We then pulled the engine and transmission from my 190E parts car. I am selling the transmission to a guy I met through Craigslist. We had to unbolt the mounts as well as the rear exhaust manifold and the exhaust down pipe. The engine has some issues but is in better mechanical shape than the one in my Sportline. If that engine dies, this one is going in, at least temporarily. I'd love to install a M112 in a W201.  Lifting it out.  Unbolting the front section of the driveshaft.  3 engines and a motor: The OM616 out of my dad's 83 240D (may be rebuilt but unsure at this point), the OM617 that is in the video, the M103, and the Leaf motor. The nest thing I did was work on my Sportline. Believe me when I say I hate working on that car. Most of the work I have done thus far has been on the front of the engine which is just a complete PITA. You have to remove the core support, radiator, and bumper to do much of anything on the front of the engine. I had not installed the adjuster backwards, it had just slipped through the hole it fits in. I fixed that and tightened up the system. I also upgraded the clutch fan to the one that Mercedes installed on the later M103s and M104s in the W124 and W126. I then installed new spark plug wires. I also reinstalled the charcoal canister with new lines going to it.   The bigger fan and the wires. We then started it up to move it out of the garage after I got it back together. Something was wrong, the belt was hitting something. I figured out that I had routed the belt wrong  . .  Rerouting the belt. A PITA with the radiator still in. Curse the Mercedes engineers who designed the belt drive on the M103 then decided to place it how they did in the w201. The engine could sit back a couple more inches closer to the firewall and all would be fine and dandy but unfortunately they didn't do that. We got the belt routed correctly but it would still not tighten up even with the tensioner fully adjusted. The belt I had on there was a Dayco W-rib belt I put on there about 200 miles ago but was slipping badly because I think the tensioner was shot. Now I'm not so sure. Either the belt stretched a ton over those 200 miles or it was missized. We measured it to be about 7mm too long which seems to show that it was just poorly sized. I have a Dayco W-rib belt on my 190D and that one is wonderful but this one seems like junk. I went an bought a slightly undersized belt just to make sure I'd have something that would work even if there was something off on the belt system on my car. My brother and Zach installed it on Thursday morning. It fit fine, doesn't slip and is quiet but it's starting to fray  . .

__________________

Current: 1975 450SEL, 83 300D, 88 Yugo GVX, 90 300D OM603 swap, 91 F150 4.6 4v swap, 93 190E Sportline LE 3.0L M104 swap, 93 190E Sportline LE Megasquirt, 03 Sprinter, 06 E500 4Matic wagon. |

|

#4

|

||||

|

||||

|

REST OF THE WEEK

I honestly don't remember the exact timeline for the rest of this so I'm just posting it like this. The next thing we did was finish up some work on my brother's 300SD. They took the old woodruff key from the old alternator and ground it down to make it fit in the new alternator. We then installed it and ran the 4 gauge ground wire to one of its bolts. We also installed the two original charge wires and a new charge wire that was somewhere around 4 gauge. We also installed a fused wire to connect up the Volvo fan relay. Currently, the fan is on high whenever the car is on, soon we will be able to install the Porsche temp switch once we get our 3/8 to 1 inch tap wrench in the mail. The thread size for the Porsche temp switch is M22 x 1.5  The original positive cable, new charge wire, and fused line for the Volvo fan relay together on a single terminal. Took some work to get them all to fit.  Almost everything installed. We then drove the car off of the ramps in the driveway and into the garage. I tried to install the shifter linkage bushings but was not successful. They are currently sitting in the freezer as some have suggested. I gave up on that and changed the rear diff fluid. Fortunately it seems the PO actually changed it at some point because it wasn't totally disgusting. This 300SD is a very clean W116 underneath, it has one rust hole from where water puddled when the windshield seal went bad (replacing soon, have both front and rear seals sitting in the garage) but isn't anything major, some surface rust in the front from the battery (replacing with AGM soon), and a little more surface rust in the trunk from moisture but otherwise is spotless. Gotta love cars that spent their whole life in Atlanta vs the rust belt.  300SD sitting in the garage which we are cleaning up to put in my 190E parts car, 190E shell for conversion to OM602, and my rusted out 190D. Another thing we did was change the oil on my Sportline. This sorta went poorly. I started early in the day but din't have the right oil filter wrench so I started working on stuff and had to run a few errands. I finally got over to the autoparts store just before they closed and picked up an wrench which seemed to fit but once I put torque on it, it just spun. I hurried back to the autoparts store to return it and try to find one that would fit but was unsuccessful. We then used a screwdriver and stabbed the side of the filter to pull it out and installed the new filter. I then started filling the engine and realized about 4.5 quarts in that I had forgotten to reinstall the drain plug  . There was 4.5 quarts of sadness laying on the ground because I had simply forgotten to reinstall the plug several hours after I had drained it . There was 4.5 quarts of sadness laying on the ground because I had simply forgotten to reinstall the plug several hours after I had drained it  . Lesson learned. . Lesson learned.Our next project was somewhat random, my brother had a reel of LEDs so we installed them in the Sprinter for some extra light.  We then loaded the Sprinter up with as many car parts I could find in the basement and garage of our other house and brought it over to the house we have the cars at.  Our next project was getting the three W201s that are being worked on into the garage so when the county inspector comes out that house next week that we don't get fined for having too many cars visible from the street. Unfortunately the path up the the garage is a decently steep slope and is not paved. It's lots of fun to have to move non-running cars into it. We started with the 190E parts car. Not so bad because the engine and transmission were out. We used our riding lawn mower and a tow strap with a person staning on the back over the rear wheels for traction to move it some and used the running 240D parts car as a battering ram to push it as close to the ramp into the garage as possible. Took a while but wasn't too much of a hassle. Next was the 190E shell which still has the engine and transmission in it. We pulled it out of the carport we had it in with the 190D then used gravity to line it up with the entrance to the garage and tried the lawn mower method again to no avail. We then tried pushing it but as the path up to the garage is not paved, we kept slipping. Zach then had an idea: lets call another one of my friends and see if he could help. He is a rather large guy, about the size of a linebacker. He was available but was at his brother's house so he brought along his brother who is even bigger and much stronger. His brother sat on the lawn mower as we pushed the car from behind and got the car up into the garage without too much fuss.  Both 190Es in  And the 190D. Most of the junk at the front of the garage is my dad's and will be moved out as soon as our storage building is cleaned and ready to fill. Bonus video: Here's the Sportline with the new fan installed, it's loud AF. https://www.youtube.com/watch?v=Tkeg4e1sgGk That's all for now, I still have to flush the coolant and change the engine mounts on the Sportline and install the AC kit on the 300SD.

__________________

Current: 1975 450SEL, 83 300D, 88 Yugo GVX, 90 300D OM603 swap, 91 F150 4.6 4v swap, 93 190E Sportline LE 3.0L M104 swap, 93 190E Sportline LE Megasquirt, 03 Sprinter, 06 E500 4Matic wagon. |

|

#5

|

|||

|

|||

|

Good work and thanks for the photos. While other college kids are driving to Daytona, you are getting 'er done. I spent a quarter as a Phd student in ME at Ga Tech long ago, but left ME because no funded projects. I only later got more hands-on w/ cars. It will serve you well in your career, even if you don't work in the automotive field.

__________________

1984 & 1985 CA 300D's 1964 & 65 Mopar's - Valiant, Dart, Newport 1996 & 2002 Chrysler minivans |

|

#6

|

|||

|

|||

|

Nice work. Nice write up.

__________________

'89 260e (212K Mi.), '92 400e (208K Mi.), '92 400e (not a misprint) (146K Mi.), '95 C220, '81 240D--Sold |

|

#7

|

||||

|

||||

|

I'm not sure about if the overkill positive cable on the 300SD does much of anything but the upgraded ground cable made all of the lights on the vehicle much brighter.

__________________

Current: 1975 450SEL, 83 300D, 88 Yugo GVX, 90 300D OM603 swap, 91 F150 4.6 4v swap, 93 190E Sportline LE 3.0L M104 swap, 93 190E Sportline LE Megasquirt, 03 Sprinter, 06 E500 4Matic wagon. |

|

#8

|

||||

|

||||

|

Great use of a spare week

__________________

1992 W201 190E 1.8 171,000 km - Daily driver 1981 W123 300D ~ 100,000 miles / 160,000 km - project car stripped to the bone 1965 Land Rover Series 2a Station Wagon CIS recovery therapy! 1961 Volvo PV544 Bare metal rat rod-ish thing I'm here to chat about cars and to help others - I'm not here "to always be right" like an internet warrior Don't leave that there - I'll take it to bits! |

|

#9

|

||||

|

||||

|

Quote:

M22x1.5 temp switch? That's much bigger than M14 x 1.5! Where are you going to mount that? I'd be curious of your fan on/ off temps when you have it running. I am experimenting (on my 85 300D) with glued on temp switches on the thermostat housing controlling the AC aux fan (viscous clutch and fan has been removed). It kicks on at the temp I want which is around 95 C, but it runs for a long time before it shuts off (when the temp gauge goes down to around 82 C). Maybe the slow response in shutting off is due to the temp switch being glued onto the stat housing. I am going to try to build an interface to the temp gauge sensor to control the fan. I am hoping it will have faster response, being in direct contact with the coolant. I don't like not having a backup fan so will eventually get a puller electric fan. Would the Volvo fan bolt in on my 300D like your bro's 300SD?

__________________

85 300D turbo pristine w 157k when purchased 161K now 83 300 D turbo 297K runs great. SOLD! 83 240D 4 spd manual- parted out then junked |

|

#10

|

||||

|

||||

|

Quote:

Unfortunately I do not think the Volvo fan will fit a 300D, it's rather thick. I can measure it to check but you may be better off using a low profile Spal fan or something similar.

__________________

Current: 1975 450SEL, 83 300D, 88 Yugo GVX, 90 300D OM603 swap, 91 F150 4.6 4v swap, 93 190E Sportline LE 3.0L M104 swap, 93 190E Sportline LE Megasquirt, 03 Sprinter, 06 E500 4Matic wagon. |

|

#11

|

||||

|

||||

|

Very interesting thread, I will be following it. Thanks for the play-by-play and the photos! The Leaf drive motor with the Diesel engine powered generator sounds like a great idea. I have often wondered why no one has done something like that. It makes sense to me that a small Diesel engine in a hybrid (or even all electric) would be so much better than a gas engine. It may have a lot to do with emissions.....Rich

__________________

All Diesel Fleet 1985 R107 300SLD TURBODIESEL 2005 E320 CDI (daily) LOTS of parts for sale! EGR block kit http://www.peachparts.com/shopforum/diesel-discussion/355250-sale-egr-delete-block-off-plate-kit.html 1985 CA emissions 617 owners- You Need This! Sanden style A/C Compressor Mounting Kit for your 616/ 617 For Sale + Install Inst. Sanden Instalation Guide (post 11): http://www.peachparts.com/shopforum/diesel-discussion/367883-sanden-retrofit-installation-guide.html |

|

#12

|

||||

|

||||

|

Catching up: Today was a day of coincidences

Just a few updates here:

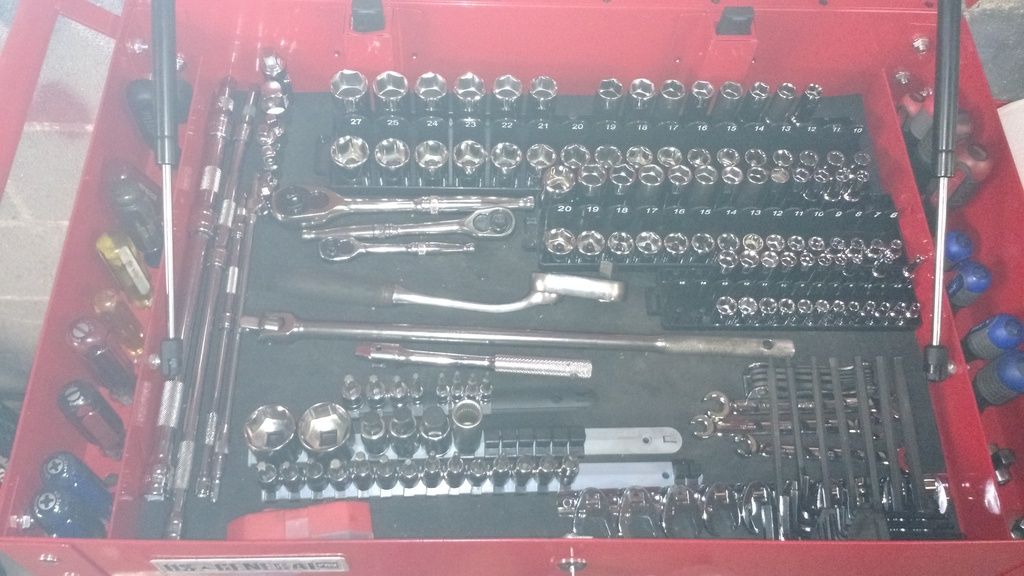

Got the bung tapped but we are having a hard time getting the bung on the spare port out, it's super tight.  We also put the CLK rims from the 300SD parts car on the 300SD because they had nice Cooper tires when the tires that came with his 300SD had cheapo non-matching Chinese tires that were very loud.  Center caps don't fit over the grease caps.  But the center caps work in the rear. These require the short lug bolts for the steelies in the rear. The car rides a heck of a lot better now. I also bought a mechanic's tool set at Northern. It's Klutch, their in house brand, which I have always been impressed with. Normally $330 for the 305 piece set, but price was at $300, then on sale down further to $255 and I had a $50 off $250 coupon so $205 for it. I bought it to go in my Harbor Freight US General tool cart which is also very nice for the price (I paid $185, seen it as low as $170). This set is awesome. I'll cover what it has in metric sizes as the SAE is somewhat pointless to me cause even the Grand Marquis mostly have metric bolts. It has 18 sizes of metric combination wrenches 7mm-24mm then 10 stubby wrenches 10mm to 19mm. It then has three metric line wrenches then a set of 10 metric crowfoot wrenches. A set of hex bit sockets , 3 of the most common sizes for torx bit sockets then screwdriver bit sockets. Folding hex key set which unlike any other of these folding types I have seen is actually robust enough to use. It also then has a variety of deep and shallow sockets in sizes from a 4mm to a 32mm. The extensions are wobble and there are 3 for each for 1/4 drive, 3/8 drive, and 1/2 drive. Universal joints and adapters for every size. It then has extremely high tooth ratchets, breaker bars, screwdrivers then a 1/4 drive screwdriver with like 30 bits. This is made in China from what I have seen with these tools, that really doesn't matter. Much better than the chinese Craftsman sets, at least on par with the excellent Kobalt sets sold at Lowes but has more useful tools than either of those. I also see Northern Tools being in business longer than Sears so I should be fine at least for a while on warranty claims. Klutch Mechanic's Tool Set — 305-Pc., 1/4in.-, 3/8in.- and 1/2in.-Drive, SAE and Metric | Tool Sets| Northern Tool + Equipment  I've put all of my metric sockets in the top of the cart. I have some of my other sets like my Kobalt torx set and my Harbor Frieght hex sets sitting in there as well, plus the OM602 delivery valve socket.  I need a wrench organizer. Here you can see my metric Gear Wrench set and one of my metric Craftsman sets (I have two, one is really my dad's but sometimes it is useful to have two of each). Of all of the wrenches in that drawer, the American made ignition wrenches in that Craftsman set are the worst quality. I try not to use them because the just slip off bolts, with not much torque required. The Chinese made combination wrenches in the Craftsman sets look ugly but are pretty good quality. I have my SAE tools in another drawer, plus have other miscellaneous tools in other drawers. I have some more sorting and sorting materials to get. Another thing I have been working on is cleaning the MFI fuel injectors from my 190E 2.6 parts car and 190E 2.3 shell. I don't have any before pictures but the ones from the 2.3 were nasty as heck. The ones from the 2.6 were not as bad but still had a lot of varnish from sitting so long. I'm hoping to get 6 of these firing correctly to put them in my Sportline. It has a wonky idle and stumbles when accelerating from idle. I figured I would start with something somewhat easy. I first let them soak in Techron injector cleaner overnight then soaked them in Purple Power with a few cycles in my ultrasonic cleaner.  Looking much better, some of them were black before.  Yuck. Purple power after they were cleaned. I then grabbed my Bergsma pop tester that I bought from a fellow forum member. I ran diesel though each of them and was able to clean up the spray a little but from time to time they would still start to leak or piss. I threw them back into the Purple Power and ran the ultrasonic cleaner a couple more times and let them sit overnight. I then took the injector cleaner and ran it through a filter funnel to get the big chunks of crap out and put the injectors back in that. At some point this week, I'll put them back on the pop tester with fresh injector cleaner with hopes that the pressure valve seats will clean up. Our next project sorta happened on a whim: I was supposed to be working on something else but Zach decided it would be easy to pull the engine from the 2.3 so we did that. He started by unhooking most everything while I was sorting my new tool set.  Getting ready.  Coming out. Getting this one to this point was much harder than the 2.6 parts car. The radiator support doesn't come out like it does on the 2.6. Notice the passenger fender is all bent up and needs to be replaced. More on that later.  Can't see it too well in this picture but as we lifted it out, a mixture of oil and coolant poured out of exhaust ports. This engine overheated and blew the head gasket.  Look at how clean the transmission housing is. Looks like it was recently rebuilt, I'll have to check with the original owner to see if that is the case if I still have her number.  All gone! That makes 5 pulled motors sitting in the garage. Yesterday I changed the shifter bushings in the 300SD. The old ones were no longer there and the car would sometimes not like to start in park. I had tried to do them the other day but couldn't get the bushing to slip in. This time I used Mercedes high temp bearing grease and they slid right in. No more issues with that aspect of the shifter. I bought the rest of the bushings for what's inside the shifter housing but replacing those will be at a much later date. Today we hit the parts yard. They said that they had a 1993 190E 2.6 so we were hoping to pull the aux fans for the 300SD, the fender for the white 190E 2.3 shell and the fan shroud for my Sportline. Me trying to pull the fender:  About that....  Unfortunately the fender was a bit shot. The aux fans were still good but the radiator was pushed into the fan and of course that fan shroud was destroyed. Of all of the 190E 2.6s I have seen in parts yards (which is probably around a dozen now), I have found 2 with the fan shroud but they were both broken worse than the one I have. I have also had no luck finding them on eBay. I'd rather not pay $80 for a new one. I also grabbed the fan resistor and tow hook cover from it. I have also only ever seen 2 tow hook covers on all of the 190E and 190Ds I have seen, which is probably around 25 by now. I could probably buy one new from the dealer as they are not too expensive. Before entering the yard, we had discussed grabbing the dual exhaust from a Crown Vic to put on out 96 Grand Marquis. Since we didn't have a battery powered reciprocating saw (the exhaust goes over the rear axle so it has tpo be cut or the rear axle dropped to grab one), I told Zach that we would only grab one if it was sitting on the ground under a car. What do we know, the first Crown Vic we see is police spec and has the dual exhaust and aluminium driveshaft sitting on the ground under it because someone had grabbed the engine, transmission and rear axle from the car.  20 more HP and more sound for the 96.  Got it in the van. I paid like $108 for everything, I should be able to get that much back by selling that aluminium driveshaft from the Crown Vic. The dual exhaust will be installed when we replace the passenger side catalytic converter. We replaced the driver's side back in January because 3 days before my dad had to take it in to do the yearly inspection, check engine light came on and we determined that the driver's side catalytic converter was bad. We figured the passenger side would go pretty soon as well as they were both replaced at the same time about 80K ago. I was looking at Advance's flyer for this month and saw that Walker direct fit catalytic converters have a $50 mail in rebate until the 31st so I told my dad about it and suggested that we go ahead and order the passenger side from Summit cause Summit has it for $80 less than Advance. He agreed but wanted to wait a couple of days to do that. The other one we put in was Walker cat. When I started the 96 Grand Marquis to take it over to the garage to install some fog lights (which didn't happen because Walmart didn't have the bulbs), I started to smell raw gas, that catalytic converter is going to throw a code very soon here.  Why the catalytic converter is getting ready to go. Still runs like a top, likely at least another 100K to go.

__________________

Current: 1975 450SEL, 83 300D, 88 Yugo GVX, 90 300D OM603 swap, 91 F150 4.6 4v swap, 93 190E Sportline LE 3.0L M104 swap, 93 190E Sportline LE Megasquirt, 03 Sprinter, 06 E500 4Matic wagon. |

|

#13

|

||||

|

||||

|

Quote:

Don't know if this is too late regarding the alternator woodruff key. I ran into a similar situation when rebuilding a Bosch alt and lost the woodruff key. I went to a local auto electric shop looking for a replacement and was told they leave the woodruff key out on all their rebuilds. He says just torque the nut down real good with an air impact.

__________________

85 300D turbo pristine w 157k when purchased 161K now 83 300 D turbo 297K runs great. SOLD! 83 240D 4 spd manual- parted out then junked |

|

#14

|

||||

|

||||

|

Quote:

As for the Woodruff key, we took the pulley off of the alternator in the 2.6 parts car and found that there was no woodruff key but we took the old key and ground it down on a grinding wheel.

__________________

Current: 1975 450SEL, 83 300D, 88 Yugo GVX, 90 300D OM603 swap, 91 F150 4.6 4v swap, 93 190E Sportline LE 3.0L M104 swap, 93 190E Sportline LE Megasquirt, 03 Sprinter, 06 E500 4Matic wagon. |

|

#15

|

||||

|

||||

|

Finally got a good tag to put on it.

__________________

Current: 1975 450SEL, 83 300D, 88 Yugo GVX, 90 300D OM603 swap, 91 F150 4.6 4v swap, 93 190E Sportline LE 3.0L M104 swap, 93 190E Sportline LE Megasquirt, 03 Sprinter, 06 E500 4Matic wagon. |

|

| Bookmarks |

|

|