|

|

|

|

|

|

|

|

|

|

|

#1

|

||||

|

||||

|

R12 vent temp 85 300D 38.5F @ 87F ambient

Just finished a 3 to 4 week long episode of work on my 85 300D's AC system by charging it with 2.9 lbs of R12 with a digital fishing scale. The only parts replaced in the system were all o-rings, Schrader valves, TXV and receiver dryer and PAO 68 synthetic oil that is suppose to be superior to mineral oil. It is note worthy that I used all the original hoses as well as the old R4 compressor, evaporator and condenser, which were pressure tested and found to have no leaks.

This video https://www.youtube.com/watch?v=gAm8zPptXlM was taken on a 2 mile drive to Autozone to return the rental vacuum pump used to evacuate the system. It was 87F ambient, car was parked in the sun with windows closed and it cooled down to 38.5F center vent temp in 2 miles of city driving. Not bad at all! In a long highway cruise, I think the vent temp can get even lower. Problem before was a slow leak that requires yearly topping up of refrigerant. I won't know if my work is successful for a few months or more.

__________________

85 300D turbo pristine w 157k when purchased 161K now 83 300 D turbo 297K runs great. SOLD! 83 240D 4 spd manual- parted out then junked |

|

#2

|

|||

|

|||

|

Very nice!

__________________

Current fleet 2006 E320 CDI 1992 300D - 5speed manual swapped former members 1984 300D "Blues Mobile" 1978 300CD "El Toro" |

|

#3

|

||||

|

||||

|

__________________

85 300D turbo pristine w 157k when purchased 161K now 83 300 D turbo 297K runs great. SOLD! 83 240D 4 spd manual- parted out then junked |

|

#4

|

|||

|

|||

|

Congrats!

__________________

'85 300D - federal spec, built in late 84. 85 300D Complete AC System Rebuild |

|

#5

|

||||

|

||||

|

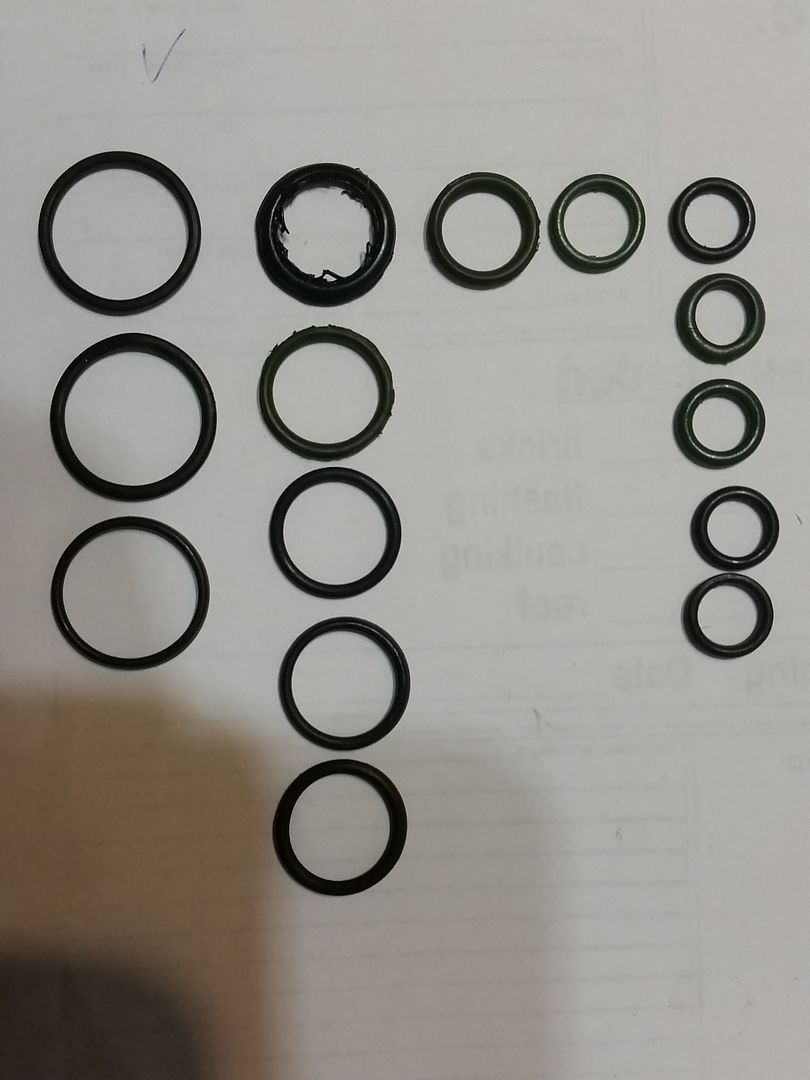

These are most of the o-rings that were removed. As you can see, some are in really bad shape. I am betting on some of them being the cause of the slow leak. Time will tell.

__________________

85 300D turbo pristine w 157k when purchased 161K now 83 300 D turbo 297K runs great. SOLD! 83 240D 4 spd manual- parted out then junked |

|

#6

|

|||

|

|||

|

Was your car always running r12? Mine had been converted to r134a sometime in the past, but still had the old O rings, and they were all much worse than yours - eaten away to the point of not being able to use them to figure out the proper size for their replacements.

__________________

'85 300D - federal spec, built in late 84. 85 300D Complete AC System Rebuild |

|

#7

|

||||

|

||||

|

I bought it already converted to R134a, the receiver dryer and TXV had green o-rings, but the rest were the original black o-rings. If all o-rings were replaced with green o-rings when it was converted to R134, I may not have the slow leak that I had.

If your o-rings are worse than mine, maybe all you needed was a flush and new o-rings.

__________________

85 300D turbo pristine w 157k when purchased 161K now 83 300 D turbo 297K runs great. SOLD! 83 240D 4 spd manual- parted out then junked |

|

#8

|

||||

|

||||

|

R12 tank hanging on the $8 digital 0-80 lb fishing scale that was used to charge by weight. I checked it's accuracy against a 0-25 lb postage scale and it is within 0.2 oz of it. The scale reads 412.9 oz before I started charging, or 25.8 lbs, which exceeds the range of the postage scale by 0.8 lbs so I was not able to use the postage scale.

Edit: For anyone thinking of using a fishing scale, the reading does not change as the tank empties (nor does the postage scale). To get a reading, I shut off the valve on the manifold, unhook the tank, recycle power, hook the tank to get the new reading. I didn't want to spend the money for a proper digital scale for AC work, which is over $100. The fishing scale is accurate enough, just not as convenient but works fine.

__________________

85 300D turbo pristine w 157k when purchased 161K now 83 300 D turbo 297K runs great. SOLD! 83 240D 4 spd manual- parted out then junked Last edited by funola; 08-25-2016 at 09:29 PM. |

|

#9

|

|||

|

|||

|

I needed a bit more than o rings and a flush. My TXV leaked badly, the potential problem with the compressor, condenser fittings were real rough, one definite bad hose, the others were questionable. I still suspect my old evaporator was leaking and/or clogged, even after flushing it. Might rig up a pressure tester or at least pressurize it under water to check for leaks. Also tempted to cut the ends of the coils off to look for clogs if it does leak.

__________________

'85 300D - federal spec, built in late 84. 85 300D Complete AC System Rebuild |

|

#10

|

||||

|

||||

|

Definitely pressure test the evaporator. It would be interesting to cut the ends off the evaporator to see if you find clogs. Mine had some restrictions when I was pumping a mix of carb cleaner/mineral spirit, then Purple power degreaser through it. The only bits that came out were what looked like o-ring material. No big blobs. I don't know if a stop leak product was used during the conversion to 134a, but my suspicion is that it was.

__________________

85 300D turbo pristine w 157k when purchased 161K now 83 300 D turbo 297K runs great. SOLD! 83 240D 4 spd manual- parted out then junked |

|

#11

|

||||

|

||||

|

Without testing with tools that are trustworthy, you are only guessing if a particular component is bad. I had UV dye in the system, but there were no signs of dye anywhere. I then bought some Mega Bubbles, and did not find any leaks with it in the accessible places. The problem is that you cannot apply the bubble solution to every square inch of the AC system nor are you able to see every square inch. I then bought a $70 electronic refrigerant sniffer from HF. At first I thought it was a great tool, but with more familiarity with it, I find that it is not trustworthy with very small leaks. Maybe a more expensive sniffer will be more reliable, even those will have limitations for very small leaks IMO. That's when I decided to pressure test each component separately and to my surprise, nothing other than the o-rings are suspect.

__________________

85 300D turbo pristine w 157k when purchased 161K now 83 300 D turbo 297K runs great. SOLD! 83 240D 4 spd manual- parted out then junked |

|

#12

|

||||

|

||||

|

Quote:

__________________

85 300D turbo pristine w 157k when purchased 161K now 83 300 D turbo 297K runs great. SOLD! 83 240D 4 spd manual- parted out then junked Last edited by funola; 08-26-2016 at 01:38 PM. |

|

#13

|

||||

|

||||

|

Quote:

EDIT: Two #10, one #8, and one #6 on the TXV

__________________

All Diesel Fleet 1985 R107 300SLD TURBODIESEL 2005 E320 CDI (daily) LOTS of parts for sale! EGR block kit http://www.peachparts.com/shopforum/diesel-discussion/355250-sale-egr-delete-block-off-plate-kit.html 1985 CA emissions 617 owners- You Need This! Sanden style A/C Compressor Mounting Kit for your 616/ 617 For Sale + Install Inst. Sanden Instalation Guide (post 11): http://www.peachparts.com/shopforum/diesel-discussion/367883-sanden-retrofit-installation-guide.html Last edited by ROLLGUY; 08-26-2016 at 11:55 AM. |

|

#14

|

||||

|

||||

|

Smallest oring is #6 found on the blue hoses at receiver dryer. There is only one #8 oring on the evap side of the TXV. The other orings on the TXV are 2 #10

__________________

85 300D turbo pristine w 157k when purchased 161K now 83 300 D turbo 297K runs great. SOLD! 83 240D 4 spd manual- parted out then junked Last edited by funola; 08-26-2016 at 01:41 PM. |

|

#15

|

||||

|

||||

|

The drier (at least the driers I sell and every other one I have worked with) use a #6 fitting (thus a #6 Oring). It could be that all the #6 fittings and hose that I buy for the hose kits I make are all labeled and packaged wrong, but I highly doubt it. You must have a bastard liquid line with a #4 on one end, and a #6 on the other.

__________________

All Diesel Fleet 1985 R107 300SLD TURBODIESEL 2005 E320 CDI (daily) LOTS of parts for sale! EGR block kit http://www.peachparts.com/shopforum/diesel-discussion/355250-sale-egr-delete-block-off-plate-kit.html 1985 CA emissions 617 owners- You Need This! Sanden style A/C Compressor Mounting Kit for your 616/ 617 For Sale + Install Inst. Sanden Instalation Guide (post 11): http://www.peachparts.com/shopforum/diesel-discussion/367883-sanden-retrofit-installation-guide.html |

|

| Bookmarks |

|

|