|

|

|

|

|

|

|

|

|

|

|

|

|

#1

|

||||

|

||||

|

Wow, there is a lot of speculation in this thread.

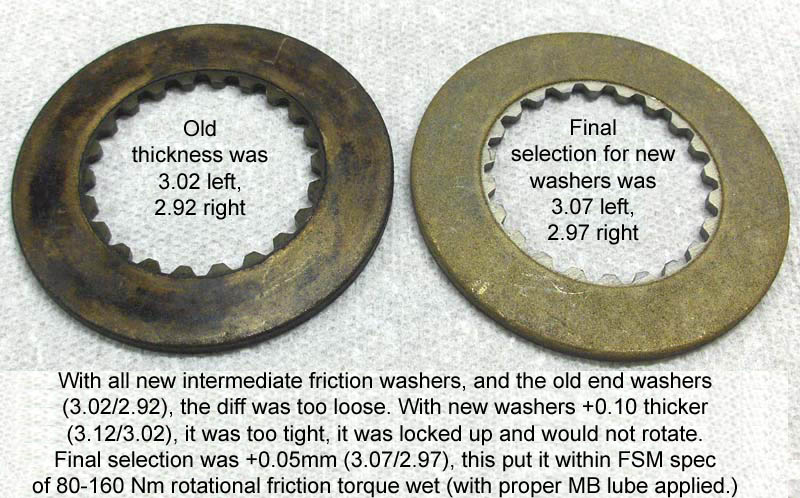

Pretty much everything MB Doc has said is absolutely correct. No W123 was available anywhere in the world with limited-slip from the factory, but yes some may have come from AMG with limited-slip. (And probably a G-T LSD, if it was from AMG.) Or someone may have installed an aftermarket conversion. If it's factory LSD, the VIN will show option code 256 in the datacard, and no, that is not stamped anywhere on the diff. There will be a little metal tag under one of the diff cover bolts, with German text specifying special diff fluid. That's it. Pretty much everything MB Doc has said is absolutely correct. No W123 was available anywhere in the world with limited-slip from the factory, but yes some may have come from AMG with limited-slip. (And probably a G-T LSD, if it was from AMG.) Or someone may have installed an aftermarket conversion. If it's factory LSD, the VIN will show option code 256 in the datacard, and no, that is not stamped anywhere on the diff. There will be a little metal tag under one of the diff cover bolts, with German text specifying special diff fluid. That's it. For the record, the only models I'm aware of that came to the USA with true LSD are the 116 6.9, the 190E-16, and all 560SEC/SEL models. The end. A handful of 124 and 140 diesels, and also a 202, had optional ASD, which is an LSD plus some hydraulics to allow 100% lock under 19mph when wheelspin is detected. ASD was more common in Europe than in the USA. The vast majority of US cars with any kind of traction control used ASR, which was an electronic simulation of LSD, but ASR cars have open diffs. ASR will reduce throttle and/or apply the brake to the spinning wheel to mimic the effect of LSD, without pesky diff clutches to wear out. Tom, about your project: Yes, the large circlips are of various thicknesses, and yes they are used to adjust the backlash. However, they are ALSO used to adjust the bearing preload! You need to measure & set both backlash & preload. Now, I know you're dead set on using the 3.27 LSD carrier with your 3.69 gears, but if it were that easy, Mercedes woudn't have created a different part number for a 3.69 LSD carrier. I will almost guarantee that you won't have enough adjustment with the circlips to correct the backlash with that setup. If you're lucky you might be able to have a spacer machined, but it will be a full custom job. Let's hope I'm wrong though.  Finally, about the friction discs. Ordering 3.2, 3.4, 3.6 is too wide of a spread. If you studied the photo below, you'll see that with the rest of the clutch pack replaced, the tolerances on the end discs were in hundredths of a mm, not tenths. I tried going up +0.2 from the old ones, for the same reason you did... "to make up for wear"... but they wouldn't fit AT ALL. Even +0.10 was too much - it would assemble, but refused not rotate; it would bind up. If your worn disc(s) are 3.2 (or less!), then +0.40 is way too big. The good news is that you can machine the back side to make them thinner as needed. I had to shave off a couple of hundredths at a time until it worked properly, which ended up at +0.05 (+0.07 was still too much). Also, remember that the thicknesses may be different left to right... if so, you must retain the delta between sides! Othewise you'll end up with one side too loose, and the other too tight. Note that mine were 0.10 different left to right. I don't know how to measure that if you lose the factory baseline, so I hope yours are the same, or your tech wrote down the number as he took it apart.

__________________

Check out my website photos, documents, and movies! Last edited by gsxr; 01-20-2008 at 09:38 PM. |

|

#2

|

||||

|

||||

|

Quote:

We were not planning to get new two sided friction discs as you did, so that is making our extra thickness in the one sided disc more in comparison to your situation. Does that sound like an ok decision to you? We also measured the wear on the non friction discs. That dimension was IIRC .0001". Just putting in all new friction discs including the one sided one would nearly put you back to the original setup with the exception that you would have the wear on the plain discs as extra clearance. So with the pretty small wear on the plain discs as the only thing not restored by replacement, you would indeed have a very slight increase in the one sided friction plate. I think I am seeing this correctly, am I missing anything? We measured the distances from the mounting position of the ring gear for the 327 ratio and the 369 ratio and they appear to be the same. How thick was the spacer that you needed? Tom W

__________________

[SIGPIC] Diesel loving autocrossing grandpa Architect. 08 Dodge 3/4 ton with Cummins & six speed; I have had about 35 benzes. I have a 39 Studebaker Coupe Express pickup in which I have had installed a 617 turbo and a five speed manual.  [SIGPIC] [SIGPIC]..I also have a 427 Cobra replica with an aluminum chassis. |

|

#3

|

||||

|

||||

|

Quote:

1) I would not leave the old, 2-sided discs in place. The only thing creating friction are those discs (and the end disc), for a total of 9 friction surfaces. Replacing one, and leaving in 8 old friction surfaces, seems like a recipe for having more slip than limited (i.e., well under 35% lock).  If the plain metal plates look OK, those can probably be re-used, but I would definitely replace all discs with friction material on them. If the plain metal plates look OK, those can probably be re-used, but I would definitely replace all discs with friction material on them.2) With all new friction discs, yes, there should only be a very small increase needed in the thickness of the end plate, possibly less than +0.10 (each side) like mine, and almost definitely less than +0.20... although I'm very interested to find out what your final selection is. When you talk to your machinist, see if he can tell you what the old discs measured, and post that info here if possible. I'd like to compare your numbers to mine. 3) About the position of the ring gear. I can't explain it, but there is something different between the carriers for different ratios that is not obvious. I went through this same thing while helping someone else with a 210mm LSD buildup. He got a carrier from a 2.47 diff, and it didn't work right with his 2.82 gears - couldn't get backlash anywhere near spec. I said yeah, there's a different carrier for 2.82's. So he bought one of those, compared them side by side, and couldn't find any difference in the mounting position. Said they appeared identical. I encouraged him to try the new/2.82 carrier anyway, even though it looked the same as the 2.47 carrier. Sure 'nuff, the 2.82 carrier cured the backlash problem, easily set to specs along with preload, and he's now happily frying both tyres. When comparing carriers, make sure you are measuring from the bearing seat to the ring gear flange; not the end of the casting. 4) I did not need any spacers for my setup... I used the correct 2.65 carrier for my 2.65 gearset, and had zero problems.

|

|

#4

|

||||

|

||||

|

He felt that the wear was negligable on the two sided friction surfaces and did not warrent replacement.

I will go back and talk with him again, probably today. Thanks again for sharing your experiences and expertise with me. Tom W

__________________

[SIGPIC] Diesel loving autocrossing grandpa Architect. 08 Dodge 3/4 ton with Cummins & six speed; I have had about 35 benzes. I have a 39 Studebaker Coupe Express pickup in which I have had installed a 617 turbo and a five speed manual.  [SIGPIC] [SIGPIC]..I also have a 427 Cobra replica with an aluminum chassis. |

|

#5

|

||||

|

||||

|

Any news on the LSD project?

|

|

#6

|

||||

|

||||

|

I got the parts in last week. He will be installing them soon I hope. He had planned to work on it Saturday but did not have a chance to do a whole lot.

I will post more later. Tom W

__________________

[SIGPIC] Diesel loving autocrossing grandpa Architect. 08 Dodge 3/4 ton with Cummins & six speed; I have had about 35 benzes. I have a 39 Studebaker Coupe Express pickup in which I have had installed a 617 turbo and a five speed manual.  [SIGPIC] [SIGPIC]..I also have a 427 Cobra replica with an aluminum chassis. |

|

#7

|

||||

|

||||

|

OK, today we assembled the diff with the new one sided friction plates.

It has excessive free play in the pinion as MBDOC and GSX said it would have. So we will be ordering a spacer to be made next week, either 4.9 or 5 mm. We will meet back at his shop this afternoon and attempt to measure it so we know how thick to have it made. It is pretty sticky with the new friction plate in it. We don't have the equipment necessary to measure the resistance of the clutches so it is a bit of a guessing game. I think we can adjust the resistance some with the lube additives. comments are welcome. Tom W

__________________

[SIGPIC] Diesel loving autocrossing grandpa Architect. 08 Dodge 3/4 ton with Cummins & six speed; I have had about 35 benzes. I have a 39 Studebaker Coupe Express pickup in which I have had installed a 617 turbo and a five speed manual.  [SIGPIC] [SIGPIC]..I also have a 427 Cobra replica with an aluminum chassis. |

|

| Bookmarks |

|

|