Aux Fan Maintenance

on the 1982 300D (OM617)

by rrgrassi

06/06/10

Aux Fan Maintenance

Last week after I had stopped the car for fuel, I went to restart, and there was a loud noise coming from the engine compartment.

At first I though it was the GP relay, then found it was something else...the Aux fan in front of the A/C condensor. After I got home, The fan seemed to work fine, but when I shut the car down and spun the fan by hand, I could hear what sounded like a dry bearing.

At first I though it was the GP relay, then found it was something else...the Aux fan in front of the A/C condensor. After I got home, The fan seemed to work fine, but when I shut the car down and spun the fan by hand, I could hear what sounded like a dry bearing. Ever heard a fan make noise on your PC? Just amp it up and that is what it sounded like on the car.

I decided to see if I could lube the bearings on this fan. I did take pictures...and so all is well. I took a 2 hour errand to day, and did use the A/C. The fan operated as it should.

Tools used:

8 mm 1/4"drrve socket, extention and wrench

Channel lock pliers

1/4" flat head screwdriver

25/32 1/2" drive socket and impact wrench. Note: I did not have a 20 or 21mm socket...

Tranny fluid

Brake Cleaner

Synthetic wheel bearing grease

What I did:

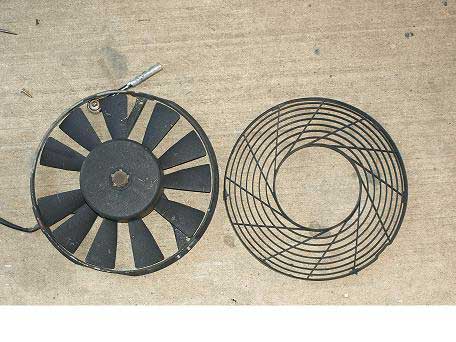

1. Unplug and remove the fan assembly from the car (8mm socket)

2. Pry off the plastic fan guard (held on in 3 places by a plastic pin molded in the guard.

3. Snip off the wire ties from the motor frame

4. Remove the fan blades (25/32 socket and impact...NOTE: This is a left handed thread, so Righty-Loosey, Lefty-Tighty)

5. Remove the 3 studs and nuts from the fan motor

6. Remove the motor cover (Pry with the small flat head screwdriver in the notches) Do not lose the spacer!!!

7. The motor cover has a ball bearing assembly in it. It is spotwelded in place, but I used brake cleaner and sprayed about a half can through the openings to removed the old grease and the grit.

8. Remove the motor stator (due to the magnets you can either use channel locks to pull straight up.

9. Check the condition of the brushes

10. Clean the bushing/oil impregnated bearing and stator shafts.

11. Put a few drops of tranny fluid in the bushing area.

12. Put a little grease on the stator shafts

13. Pack the ball bearing with grease, and use a little grease on the spacer to act as a seal.

14. Put stator assembly back into motor housing. Make sure is seats fully.

15. Replace motor cover. (test spin by hand. You will feel restistance from the brushes.

16. Reassembly is opposite of disassembly.

Discuss this DIY here.

-rrgrassi

CategoryDiy