Revision [690]

This is an old revision of W210EngTransMounts made by WebMaster on 2009-06-14 16:50:14.

Diesel Engine, Transmission Mounts + Shifter Bushing Replacement

on the 1999 E300D (W210)

by uberwgn

5/30/09

Replacing engine and transmission mounts, green shift linkage bushing

Subject car: 1999 E300D

My car has about 70,000 miles on it. While my mounts were not shot, I could tell the engine was sinking lower. I’d sometimes hear the fan hit something when I was starting up a very steep hill. I could also feel a bit of vibration through the body of the car when first starting on a very cold day.

The engine mounts are about $150, transmission mount was about $32 and the green busing is a couple of dollars.

I’ll repeat common sense warnings: It’s potentially very dangerous to work under a car unless you’ve got a 4-post lift or some other type of lift. Using jack stands, as I did, is the least desirable method. Someone was killed in my area about a week before I performed this job when his vehicle fell off the jack-stands and crushed him. It makes me apprehensive. Exercise extreme caution when working under the car. Do NOT use cheap jack stands.

I’ve been putting off this job for a long time. I thought it was far more complex based upon the various write-ups I’ve seen. This job is not complicated and I would have completed it long ago if I had a better understanding.

1. Raise front of car and support in a safe manner.

2. I removed the two clips from the engine fan shroud to ensure I didn’t have any clearance issues when lifting the motor.

3. Remove front engine cover (which you would if doing ordinary oil drain) and rear cover if you are to do the transmission mount and shifter bushing.

4. Support the oil pan with a floor jack, using a piece of plywood and a something soft between jack and oil pan. Do not raise the engine at this time.

5. You will do one engine mount at a time.

Start with the passenger side - it’s easier and will build your confidence. The top bolt is 16mm, the lower is 13mm (accessed through a hole in frame). 12pt sockets are a real benefit for this task. There’s a heat shield near the turbo which you could remove to view the job a bit better. Also, a universal joint is quite helpful for this upper bolt.

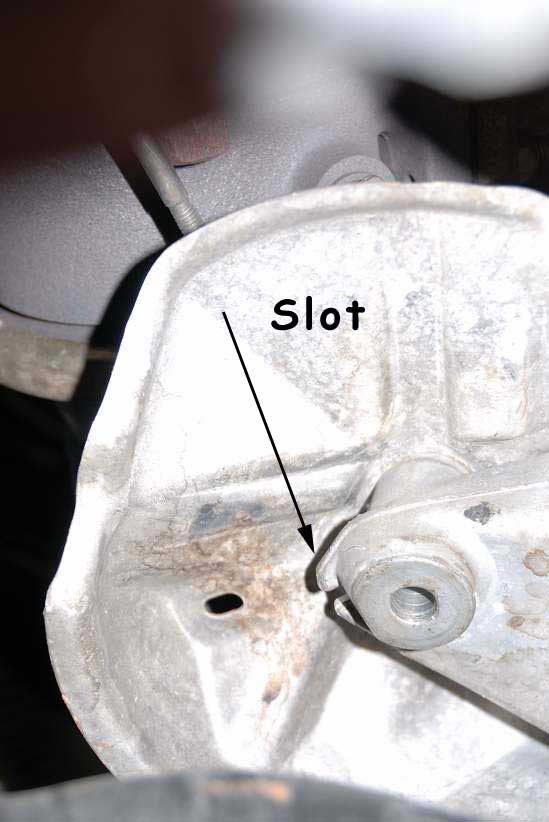

6. Remove bottom bolt from below (seen through a hole in sub-frame), and using extensions/U-joint remove upper bolt by snaking the extension under the intake from the front of the engine. Now lift the engine slowly until you can cleanly remove the mount from below. Install new mount from below, being sure tab protrudes through nice boot and aligns with slot on engine bracket. You may need to lift engine a bit more if your mounts are collapsed. It takes very little effort to lift the engine with the floor jack. Now install upper bolt and tighten, drawing mount upward and ensuring that tab is where it needs to be (you can see it with some difficulty from above it as you tighten). Carefully lower engine and install lower bolt (I’m fairly certain there was thread locker on the upper bolts only).

7. Driver’s side: A bit more challenging - I found access to the upper and lower bolts somewhat more challenging. Support but do not lift oil pan once again. Remove lower bolt as above, then from top front and again using a U joint adapter, remove the top bolt. A 10mm socket can be used to remove the heat shield - I did in order to see proper alignment of new mount but you may be able to leave it in place). Slowly lift engine with jack and remove oil mount from below. As above you need to raise the engine further to install fresh mount from below, again observing the tab alignment. Back up top, loosely install heat shield bolt (if removed) and align the shield to install the top mount bolt from above. I used a magnet to drop it in place. You cannot verify tab engagement from above, you need to go below and support mount while hand-tightening the upper bolt until you are satisfied the tab is where it needs to be. Then back up top to tighten heat shield bolt and engine mount. As before, slowly lower engine and install lower bolt from below.

8. TRANSMISSION MOUNT: Put the new shifter bushing in you pocket and grab needle nose pliers before climbing back under car yet again. Move the jack back under the transmission oil pan and support but do not lift. Remove lower bolts (ties mount to sub frame) which are thread locked with 13mm socket. Now loosen but do not remove (if possible) the mount for the belly pan - it interferes with right side mount-to-transmission bolt. Now is a good time to peer around at your car, drive shaft flex disks, etc to look for potential issues. Raise transmission slightly and remove upper horizontally located bolts (16mm, ties mount to transmission case) and remove old mount. Install new mount in reverse. Lower bolts had (Loctite®) thread lock on them. Reinstall that bracket for the rear belly pan. Lower jack and move it out of the way.

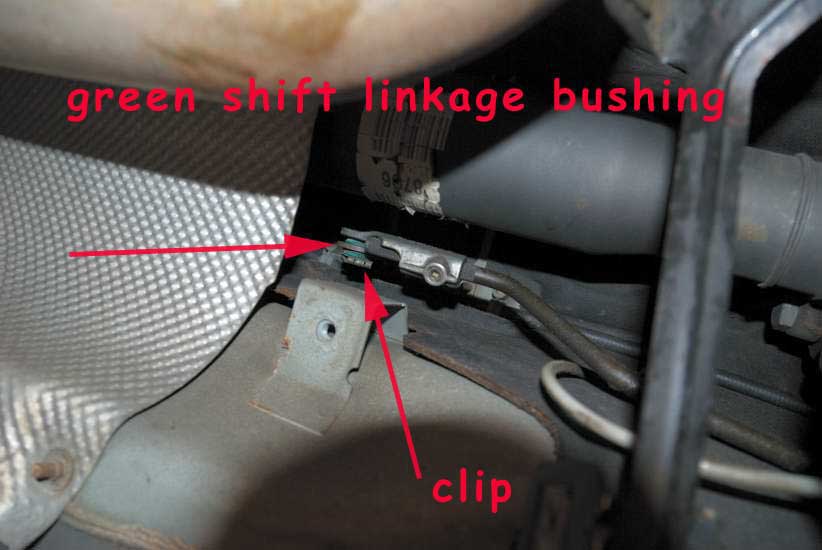

9. SHIFTER BUSHING: With the 13mm socket, remove the 2 bolts that hold a brace/drive shaft failure catch bracket in the way of your work. Transmission should be in Park.. Using needle nose pliers remove the spring clip/retainer. This little clip is tricky to remove. I found a revised part in EPC and ordered it. It looks pretty much like the original one.. Remove relay rod from shifter shaft, install new bushing onto rod and slip assembly back into shifter shaft. Now squeeze forcefully but carefully with pliers to press bushing into shaft. I had to slide the relay rod out to continue to use pliers to press the bushing in. One seated, install relay rod and spring clip. Reinstall the bracket you removed. Put belly pans on, lower car.

Thanks to forum member Bob T. for performing the basic write-up!

Remove the two plastic clips that hold fan shroud in place:

Supporting the car with jack stands:

You could remove this heat shield to have a better view of the top of the mount (I did not remove it):

I could see just a bit of oil leaking on the top of this mount once removed from vehicle:

Tab on mount inserts in this slot:

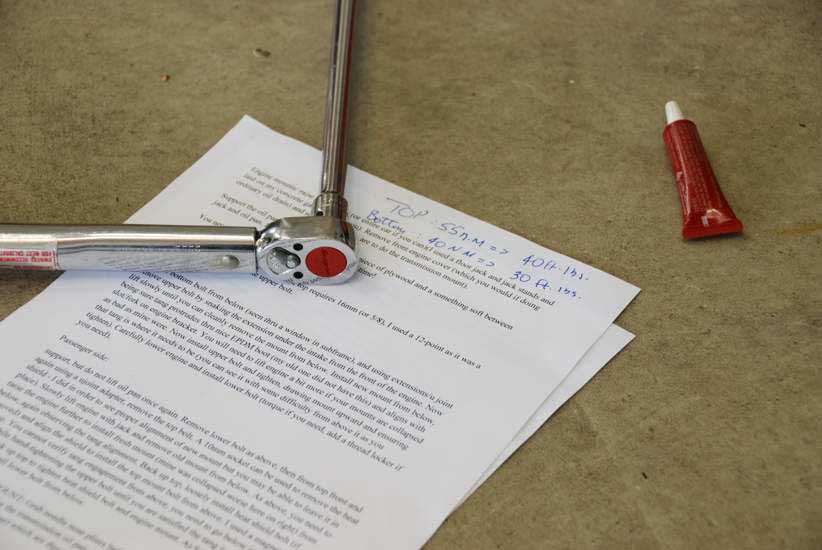

Somebody provided these torque values for upper and lower engine mount bolts:

There are likely a variety of methods to remove the top engine mount bolt on the driver's side. You are pretty much blocked by the intake manifold so I went in with a very long extension and my u-joint attached to the 16mm socket. I could get a box wrench on the bolt from underneath the car, but could not get enough leverage on it due to being on the ground and not having much clearance for my arms to break it loose:

I did not have a tiny, deep socket to remove the fasteners holding this bracket in place so I had to bend it out of the way to gain access to one of the transmission mount bolts:

The place I ordered several parts from sent me the two white bushings in error. I believe they're for the W124 car. I only needed the green bushing in the center:

Even though this green bushing did not appear to be "worn", replacing it made the shift lever in the car quite a bit tighter, all slack has been eliminated It's a bit tricky getting this little bushing re-installed - - I put some rubber lube on it to help get it back in place. It's made of a hard plastic-like material. It's not very flexible. Working under the car (and taking pictures) with minimal clearance is a PIA.

I realized this hard plastic lift pad was missing from my car after seeing it on the wife's '02 wagon. It is attached to a frame cross member, just to the rear of the oil pan:

Discuss this DIY here.

-uberwgn

CategoryDiy