Quote:

Originally Posted by sasquatchgeoff

Not sure what happened, when the injectors were pulled for the initial rebuild, two were completely blown (held no pressure) two were off spec (85, 90 bar) and one was about 129. Not completely familiar with the shim/pressure relationship, but the #5 injector may have had a shim settle more than the others?

Of course now I am keeping a close ear for the other four and if any of them start to nail I know where to start first.  |

It could be that dirt or something got trapped under or between the Shim pack and the Pop pressure was OK when tested. Later it got smashed or worked it self out.

Also it is one of the least skilled jobs in a Fuel Injection shop; it may be that they were training someone or just in a hurry.

The thing about shimming the Injectors is that each Spring from each Injector will not have exactly the same tension (ounce in a while they also break), the dimensions of the Injector parts that effect the pressure are also different. Hence the need to use shims to adjust the pressure.

If you ever rebuild your own set keep the parts from each Injector segregated from the others; it makes them easier to shim.

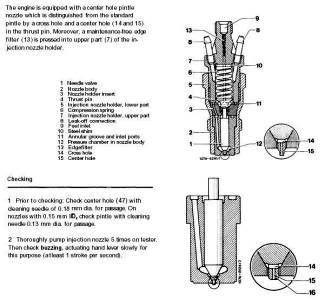

Your Spray Nozzle may not look like the one in the pic; used to show the relationship of the Spring #8 and shims #10.