Torquing the new cylinder head

Torquing the new cylinder head pictures by whunter - Photobucket

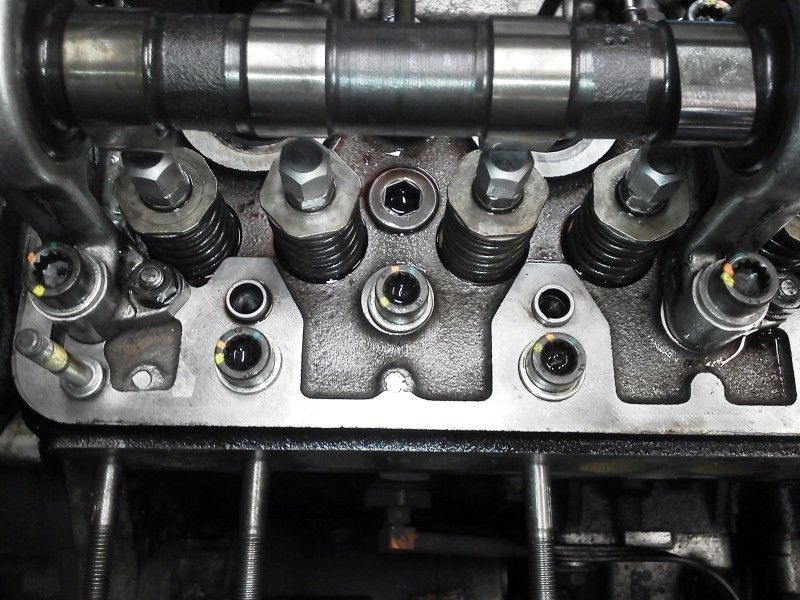

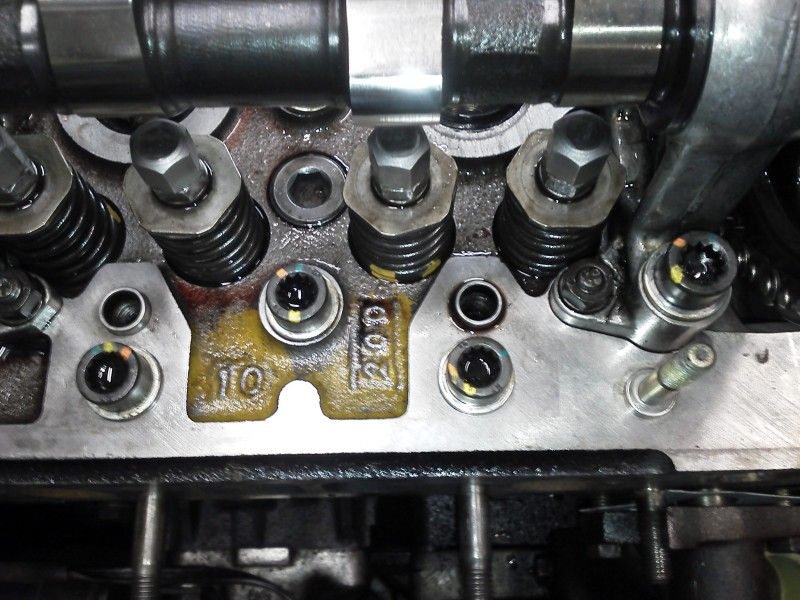

Please note the paint dots on the bolt heads..

This is a procedure used in R&D prototype, where a mistake can cost millions.

Tighten the fastener and paint mark it, if there is more than a one step one torque = use a different color for each torque step.

There are FOUR torque steps on the OM616 cylinder head bolts = four color dots on each bolt head.

The procedure is elegant:

#1. Torque the fastener.

#2. Paint mark the fastener.

#3. Go to the next fastener.

As I recall the OM616 requires:

Quantity Four 115 MM bolts.

Quantity Eight 120 MM bolts.

Quantity Six 145 MM bolts.

.