Well, the problem is solved. The thermostat on my spare engine shows what is the proper, fully collapsed position for the plunger at ambient temps. This is the 95 degree module however.

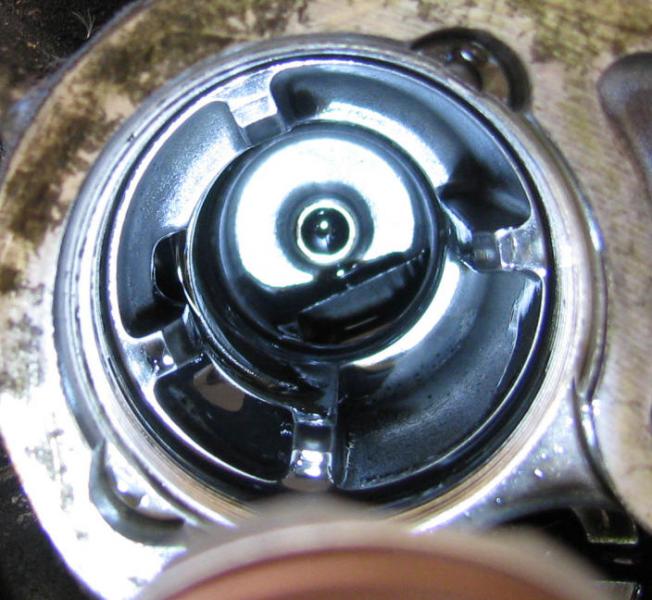

And for the inquiring minds, here is the bore of the thermostat. Note how the bore runs deep for the 160 degrees or so to the left (between the three left-most "tabs". The right-most 200 degrees or so (except for the "tab" that keeps the piston centered is cut away deep). There is about 1/4 inch or so at the bottom that the piston rides in for a full 360 degrees - the closed position. Once the plunger begins to extend, the piston rises to uncover a path for the oil to flow through the cooler.

This makes 2/3 of my engines with a stuck-open thermostat. Without my engine instrumentation sensors, I would have never known. I'm either extremely unlucky or these fail with greater frequency than anyone realized. Fortunately, I drive a lot and for large distances and this profile has likely limited the negative effect of condensation building up in the oil to the detriment of the engine. I'm sure that even though the engine sump oil is only at 150F normally, as it transits the valve train, bearings, turbo etc. it sees 100C and higher, driving off condensation. Nevertheless, I'll change this out at first opportunity.

I guess the conclusion is - check your oil cooler thermostat for proper operation.

If I didn't have my oil temp sensor, I'd be inclined to get something like this to put down the dipstick tube to verify things are working properly. Dirt cheap, but it only needs to work once -