|

|

|

|

|

|

|

|

|

|

|

|

|

#1

|

||||

|

||||

|

A Question for the Injection "Masters"

Assuming the following:

- rebuilt, calibrated original set of injectors - rebuilt head, including prechambers, valve guides, seals - non-contaminated fuel With no apparent fuel leaks, can worn delivery vales/sealing washers & rings be the cause of nailing? If so, how?

__________________

327K on 1986 W201, 602.911, 722.414 2.5 190D ("The Red Baron") 139K on 1993 W124, 104.942, 722.433 2.8 300E ("Queen") http://farm5.static.flickr.com/4081/...0bb92d3c_m.jpg http://i370.photobucket.com/albums/o...g?t=1325284354 Do not worry about your difficulties in Mathematics. I can assure you mine are still greater. - Albert Einstein take a walk down memory lane... Last edited by sasquatchgeoff; 07-17-2009 at 03:44 PM. |

|

#2

|

|||

|

|||

|

I say no but I will wait for others to weigh in also.

Nailing is caused by a bad spray pattern most fruequently.

__________________

Dionysius |

|

#3

|

|||

|

|||

|

Quote:

Your OP was and I quote: "Assuming the following: - rebuilt, calibrated original set of injectors - rebuilt head, including prechambers, valve guides, seals - non-contaminated fuel With no apparent fuel leaks, can worn delivery vales/sealing washers & rings be the cause of nailing? If so, how? " So my answer held true because you did NOT have properly calibrated injectors. Properly calibrated injectors isolate the spray formation and pattern from pump issues (except for timing...of course) due to the pop pressure being the final arbiter in the sequence. This is not about me being right or wrong (no ego tied up here! ) but I would like you to privately acknowledge that I did not mislead you

__________________

Dionysius |

|

#4

|

||||

|

||||

|

Quote:

I believe the Delivery Valve Crush Washers on your IP sit between the Delivery Valve body and the Delivery Valve holder (that the Hard Lines Attache to); so unless some one reused them I would not think that they would have a wear issue and should seal. I believe I have read of some nailing caused when the O-rings leak but I am not sure why this would be the case. I would be more inclined to think the Nailing was caused by IP timing not being correct. By "rebuilt, calibrated original set of injectors" did this mean brand new Nozzles and Opening/Pop Pressure set on them? And, who did the rebuild? Does the Nailing ever go away? Any other issues like smoke? Do you know if anyone was inside of the IP; for instance to change the Delivery Valve Holder O-rings?

__________________

84 300D, 82 Volvo 244Gl Diesel |

|

#5

|

||||

|

||||

|

1. Indie mechanic removed #1 delivery valve to check timing. (took it to indie thinking that nailing was indication that timing was off) Timing was less than 1/2 degree off so he left it alone. He replaced DV holder o-ring. Miraculously (or coincidentally??) after reconnecting the line the nailing went away. Slowly, about 500 miles later the nailing reappeared, only milder.

2. Injectors rebuilt by Diesel Injector Service in Portland. Certified Bosch technicians - very busy shop. New nozzles and opening/pop set confirmed. No real smoke - maybe a little at start-up - especially when its in the "nailing mode." My pump utilizes both copper crush and o-rings. See here

__________________

327K on 1986 W201, 602.911, 722.414 2.5 190D ("The Red Baron") 139K on 1993 W124, 104.942, 722.433 2.8 300E ("Queen") http://farm5.static.flickr.com/4081/...0bb92d3c_m.jpg http://i370.photobucket.com/albums/o...g?t=1325284354 Do not worry about your difficulties in Mathematics. I can assure you mine are still greater. - Albert Einstein take a walk down memory lane... |

|

#6

|

||||

|

||||

|

The only other thing I can think of is perhaps a small amout of air is getting in.

Also while I have not read it at the below site in the manual there is some sort of modification to the Overflow Valve; in the manual. I have not read it as I do not have that Engine or IP so I do not know the details or what problem it is supposed to solve. http://www.ps2cho.net/downloads/MB%20CD/W124/Main.html Random thoughts: Is it possible that the EGR/Smog system could be causing the Nailing? Too much exhaust gas mixed with the fresh air might be causing late burning of the Fuel? Is the Engine operating temp normal? I also remember folks complaining of the inside of their Intake Manifolds getting really cruddy to the point they are difficult to clean. Also it seems that after 1985 model year or so there is more complaints of nailing. Rebuilt Injectors and Timing set properly usually cure a 617 that has good compression and no air leaks.

__________________

84 300D, 82 Volvo 244Gl Diesel |

|

#7

|

||||

|

||||

|

Thanks Diesel911,

I think I have the problem solved. A faithful friend brought a stethoscope to locate the responsible cylinders/injectors and it turned out to be only one. #5 had a pronounced knock at the RPM that was most prone to elicit the nailing while all the other cylinders appeared to be the same. Once I determined that there was only one misfiring cylinder, we jumped in the car and drove to the injector shop where I originally had them rebuilt. Took the #5 injector out and gave it to the shop owner. He invited us to come back and watch him pop-test and verify opening pressure. It consistently showed 121 bar. He remarked that it was off, but that "it shouldn't be a miss." He offered to disassemble and reset the pressure. Readjusted to 140 bar, I re-installed the injector/line and the nailing went away. Just goes to show that you have to make sure of injector adjustments, and that if you are having someone else rebuild them for you, a trust relationship is valuable. Car runs like it should now.

__________________

327K on 1986 W201, 602.911, 722.414 2.5 190D ("The Red Baron") 139K on 1993 W124, 104.942, 722.433 2.8 300E ("Queen") http://farm5.static.flickr.com/4081/...0bb92d3c_m.jpg http://i370.photobucket.com/albums/o...g?t=1325284354 Do not worry about your difficulties in Mathematics. I can assure you mine are still greater. - Albert Einstein take a walk down memory lane... |

|

#8

|

||||

|

||||

|

Quote:

I wounder what happend when they did the origional Injector Rebuild; since rebuilding the Injectors is many times simpler than rebuilding a whole IP.

__________________

84 300D, 82 Volvo 244Gl Diesel |

|

#9

|

||||

|

||||

|

Not sure what happened, when the injectors were pulled for the initial rebuild, two were completely blown (held no pressure) two were off spec (85, 90 bar) and one was about 129. Not completely familiar with the shim/pressure relationship, but the #5 injector may have had a shim settle more than the others?

Of course now I am keeping a close ear for the other four and if any of them start to nail I know where to start first.

__________________

327K on 1986 W201, 602.911, 722.414 2.5 190D ("The Red Baron") 139K on 1993 W124, 104.942, 722.433 2.8 300E ("Queen") http://farm5.static.flickr.com/4081/...0bb92d3c_m.jpg http://i370.photobucket.com/albums/o...g?t=1325284354 Do not worry about your difficulties in Mathematics. I can assure you mine are still greater. - Albert Einstein take a walk down memory lane... |

|

#10

|

|||

|

|||

|

Quote:

My concern now is the other four. If the shop cannot set one of them properly, why should we believe the other four are on spec? The lack of nailing is not the definitive answer to a proper job. How smooth is the idle? If it's not like a gasser, I'd pull the other four and take them back as well...........let him prove that they are all at 140. |

|

#11

|

||||

|

||||

|

Quote:

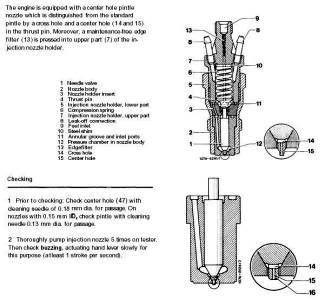

Also it is one of the least skilled jobs in a Fuel Injection shop; it may be that they were training someone or just in a hurry. The thing about shimming the Injectors is that each Spring from each Injector will not have exactly the same tension (ounce in a while they also break), the dimensions of the Injector parts that effect the pressure are also different. Hence the need to use shims to adjust the pressure. If you ever rebuild your own set keep the parts from each Injector segregated from the others; it makes them easier to shim. Your Spray Nozzle may not look like the one in the pic; used to show the relationship of the Spring #8 and shims #10.

__________________

84 300D, 82 Volvo 244Gl Diesel Last edited by whunter; 09-13-2009 at 07:30 PM. Reason: spelling |

|

#12

|

||||

|

||||

|

Mystery solved

Quote:

Mind you this is an abridged version of a detailed story that relates a nailing problem that would surface slowly after purging air from my fuel system. I thought I had it fixed after I discovered that the injectors were not popping precisely within spec and made the shop reset them all three times. The shop was great, they were consistently nice to me, every time I went in there they gave me free goodies like return line hose, loan of special socket to remove delivery valves, and notepads/pens in addition to pop testing and calibrating my injectors for free three separate times. This shop was a great place to learn, I ran into some "old timers" (including a Stanadyne rep) and these guys felt pretty strongly that air infiltration was my problem. After many trips to the injector shop, setting the pop pressure at 120, 138, and back to 125 in succession, 5 sets of injector heat shields, countless fuel hose clamp tightening operations, replaced primary filter, many sleepless nights visualizing my fuel delivery circuit, and expecting the inevitable horror of pulling my IP, I have solved this mystery wrapped in a riddle inside an enigma. When inspecting my secondary filter I discovered that as a result of over-torquing the hollow screw to hell and back, the center rubber seal in the canister was chewed up and distorted leaving the opportunity for the return fuel to mingle with the delivery fuel (see my latest thread). While I had the secondary fuel filter housing and canister off, I replaced the three connectors that link the housing/canister to the IP (milky white translucent plastic dealer items w/banjo and compression fittings). Put it all back together and presto, nailing problem solved. Whether the problem was caused by the filter or by the IP/fuel filter connectors, I don't know but the car runs like a new one now. I wanted to let everyone know that all is well and I am ready to tackle the next problem. I have learned to slow my tortured brain down and expect the simplest solutions to be the secret to success.

__________________

327K on 1986 W201, 602.911, 722.414 2.5 190D ("The Red Baron") 139K on 1993 W124, 104.942, 722.433 2.8 300E ("Queen") http://farm5.static.flickr.com/4081/...0bb92d3c_m.jpg http://i370.photobucket.com/albums/o...g?t=1325284354 Do not worry about your difficulties in Mathematics. I can assure you mine are still greater. - Albert Einstein take a walk down memory lane... |

|

#13

|

||||

|

||||

|

LOL!

__________________

84 300D, 82 Volvo 244Gl Diesel |

|

#14

|

||||

|

||||

|

It might be nice to repeat the name of the Fuel Injection Shop you got such great service from.

__________________

84 300D, 82 Volvo 244Gl Diesel |

|

#15

|

||||

|

||||

|

Diesel Fuel Injection Service - Portland, OR

__________________

327K on 1986 W201, 602.911, 722.414 2.5 190D ("The Red Baron") 139K on 1993 W124, 104.942, 722.433 2.8 300E ("Queen") http://farm5.static.flickr.com/4081/...0bb92d3c_m.jpg http://i370.photobucket.com/albums/o...g?t=1325284354 Do not worry about your difficulties in Mathematics. I can assure you mine are still greater. - Albert Einstein take a walk down memory lane... |

|

| Bookmarks |

|

|