|

|

|

|

|

|

|

|

|

|

|

|

|

#1

|

|||

|

|||

|

W123 300D Oil Cooler - thread issue

Hi

Has anyone experienced a buggered thread when removing the oil cooler line from the oil cooler? I have a hose clamp holding mine on but fear if it ever came off my engine would sieze. It looks like the male nipple(sticking out of oil cooler) is aluminum as is rest of oil cooler - I put a magnet on it and it did not stick. It also looks like a poor design with not that many threads. Anyway a new oil coiler is very expensive so i am considering getting someone to weld a steel male nipple onto oil coiler replacing the "soft" aluminum one it came with. The best I can figure is the male nipple (that oil cooler hose connects to) is 22mm OD & about 13mm long with a pipe thread of 1.5mm not sure what inner diameter is. My hunt is on for an allthread steel pipe, 13mm long and 22mm OD with 1.5mm pipe thread. I talked to a radiator repair guy and he knows a way to braze steel to aluminum - so if I can only find the allthread pipe I would be in busineess. Any help is appreciated |

|

#2

|

||||

|

||||

|

It is somewhat common f0r the Threads on the Aluminum Nipples to strip. It also happened to me.

In the below threads at the end there is a Mercedes authorized repair that is exceptionally good. See the repair thread before doing this; to summarize; you cut off the old Nipple, drill and tap the inside for M18x1.5 threads and you can get new Steel Nipples to fit in there it rather cheaply from Mercedes. They are the same steel Nipples that Screw into the bottom of the Oil Filter Housing where the Oil Cooler Hoses attach there. OSH Hardware has the Tap for around $13 (made by Vermont, another inexpensive company is Hanson). However, the proper drill with a reduced shank can be a little expensive if you do not get it on the internet or do some serious shopping. The M18x1.5 thread size is the same as Spark Plug size many older US Cars used to use. There is 2 good repair threads and the part numbers and stuff are there. DIY Repair Links http://www.peachparts.com/shopforum/diy-links-parts-category/ http://www.peachparts.com/Wikka/DoItYourSelf

__________________

84 300D, 82 Volvo 244Gl Diesel Last edited by Diesel911; 07-18-2011 at 08:44 PM. |

|

#3

|

|||

|

|||

|

The oil filter housing has steel nipples that just happen to fit cooler lines. Procure a couple of those and drill/tap the cooler.

|

|

#4

|

||||

|

||||

|

Quote:

__________________

84 300D, 82 Volvo 244Gl Diesel |

|

#5

|

|||

|

|||

|

thx

thx for the quick feedback guys I appreciate it

|

|

#6

|

|||

|

|||

|

Folks NEVER take the nut off the cooler lines to remove them without some type of loosening oil applied before. Put some KROIL on it the day before and then the hour before and then a light tap with a hammer and more KROIL. Oil cooler thread strip quicker than you can blink.

|

|

#7

|

|||

|

|||

|

I purchased a second oil cooler from a junkyard over the weekend Already have male nipple adapter from mb dealer. here's the situation I cut off metal lines from oil cooler hose so I could put a 27mm deep well socket on the hose fitting. My breaker bar is 16" long and i added another 9 inch pipe for leverage. I have sprayed penetrating oil on the threads about a dozen times and gently tapped the fitting. Need a second hand to hold down end of oil cooler cause it is not breaking loose for me. Considering adding some heat (ie torch) to loosen it up - is this a wise idea?

Another post mentioned using a dremel to cut the fitting. Don't own one of those. If I do get this off and threads are not buggered great - if they are buggered - how about this idea cut off smaller diam side of mb male nipple adapter and have someone weld nut from adapter to the nut on oil cooler (assuming I have cut male nipple off and filed down sufficiently to make it smooth)? Seems easier then procuring a 21/32 inch dril bit and a 18mm with 1.5 mm pitch tap. Local harbor freight does not stock these. |

|

#8

|

|||

|

|||

|

Quote:

__________________

80 300SD (129k mi) 82 240D stick (193k mi)77 240D auto - stick to be (153k mi) 85 380SL (145k mi) 89 BMW 535i 82 Diesel Rabbit Pickup (374k mi) 91 Jetta IDI Diesel (155k mi) 81 VW Rabbit Convertible Diesel 70 Triumph Spitfire Mk III (63kmi)66 Triumph TR4a IRS (90k mi)67 Ford F-100 (??) |

|

#9

|

|||

|

|||

|

I had someone hold other end of oil cooler down and I was able to loosen up each fitting using breaker bar with 27mm socket - stopped and sprayed some more penetrating oil near each fitting- will let that soak in for awhile before my next attempt

|

|

#10

|

|||

|

|||

|

^^ be afraid....alloy threads in steel do not fare well with force....

__________________

80 300SD (129k mi) 82 240D stick (193k mi)77 240D auto - stick to be (153k mi) 85 380SL (145k mi) 89 BMW 535i 82 Diesel Rabbit Pickup (374k mi) 91 Jetta IDI Diesel (155k mi) 81 VW Rabbit Convertible Diesel 70 Triumph Spitfire Mk III (63kmi)66 Triumph TR4a IRS (90k mi)67 Ford F-100 (??) |

|

#11

|

||||

|

||||

|

Quote:

That was due to a piece of the Aluminum Thread that stuck to the Steel Threads of the Nut. If you know about Anodizing Aluminum when Aluminum combines with Oxygen it becomes hard. The hard Aluminum Tooth cut up the 3 end threads.

__________________

84 300D, 82 Volvo 244Gl Diesel |

|

#12

|

||||

|

||||

|

Here's what I found:

The 1st thread on the female part had some corrosion on it and buggered my cooler threads when I backed it off. If the rust/corrosion/funk, is harder than the aluminum then the cooler is going to lose...

__________________

My occupational hazard bein' my occupation's just not around... 1980 300SD 1980 300SD |

|

#13

|

|||

|

|||

|

If you have a junk yard unit then the best bet is to cut the nut with the dremel or a hacksaw (carefully) and then use a screwdriver to separate it and you can then put the new lines on with the unit installed.

|

|

#14

|

|||

|

|||

|

I finally removed both fittings and was was fine and I buggered the other one. Took original cooler to a machine shop and they did the recommended mb repair. They cust off alum male nipples, filed nut down to get smooth, then drilled w 21/32"drill bit and tapped with a 18mm x 1.5 pitch thread and inserted mb washer and mb adapter. I was not sure to use loctite on 18mm pipe thread side or just tefflon tape - any recommendations?

|

|

#15

|

||||

|

||||

|

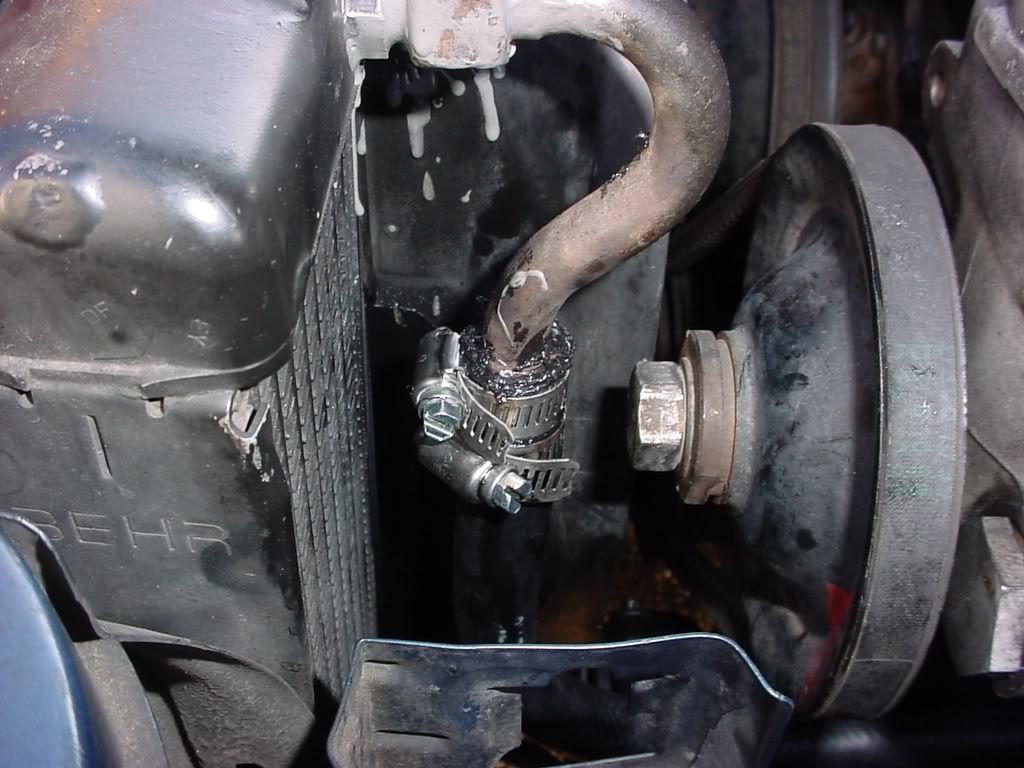

Not a real good pic of what I want to show. When I stripped my upper Nipple on the Oil Cooler I lost the front 3 threads. That meant there was still some threads left.

(This is before I read about the Factory Autohrized Repair in our Forum.) I degreased the Nipple and Hose Nut with Brake Cleaner coated the Threads with JB Weld and and screwed it back onto the Oil Cooler and it has been there since Sep, 2007 with no problems. you have to look at the top of the Photo to see where the JB Weld oozed out. (Since that time I have bought the Tap, Drill and Fittings and someday will do the correct repair.)

__________________

84 300D, 82 Volvo 244Gl Diesel |

|

| Bookmarks |

|

|