I like the idea of being able to track engine hours as a cross reference for maintenance using a Hobbs meter.

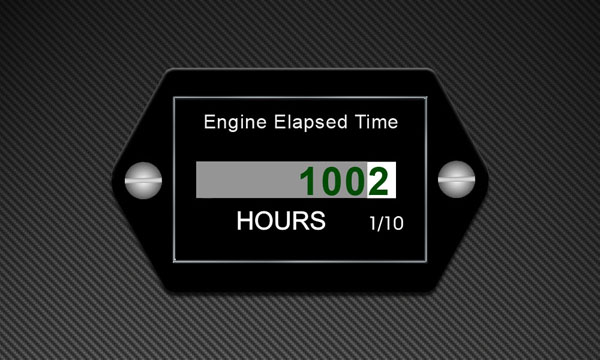

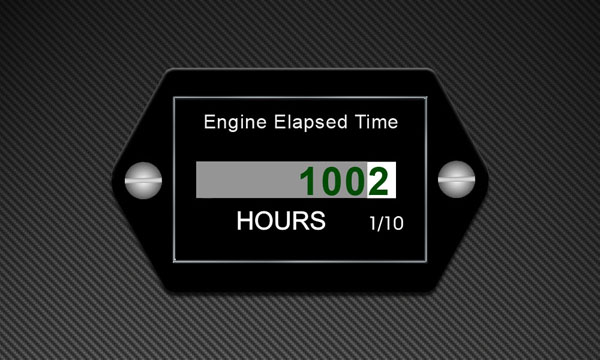

Here's the dedicated hour meter screen as implemented on the tablet.

There are two primary ways of managing and tracking maintenance options on diesel engines - mileage and hours. In almost all cases mileage is the default method for cars and trucks, but for other engine platforms, e.g. boats, planes, generators, pumps, equipment, etc, hours is the method used. A Hobbs meter only counts elapsed time when the engine is running. The easiest way to trigger counting time is when the "key is on". Unfortunately there are many times that the key is on and the engine is not running so meters often use a tach signal or oil pressure switch as the triggering event to count time.

In designing a system to add a Hobbs meter to my gauges project, I originally thought of adding another stand alone Arduino to the car for this purpose, but figuring out a display strategy that would not involve cutting up the dash in some way was not to be. Then I thought of passing a signal from a second Arduino to my engine instrumentation display and after researching this determined this was just too complex. So I went back to the idea of adding this functionality within the existing system - after all I already monitor fuel pressure and vacuum and have the display so the solution could be done completely in code. With both fuel pressure and vacuum, there is an engine driven pump that produces a pressure change when the engine is running. My first thought was to use fuel pressure because it is very responsive to engine start/shutdown. Unfortunately it has wild swings which could trigger an engine off false alarm. Vacuum, on the other hand, is extremely stable, but bleeds off relatively slowly. Since almost all engine shutdown signals will be key-off this will come into play only occasionally. I've selected 10 inHg as the vacuum level for start/stop detection. The design basically monitors vacuum and engine state. When the engine comes on the current Hobbs meter reading is fetched from the Arduino eeprom and a counter is started tracking the elapsed time. The engine run time is updated in eeprom once a minute (this is because the Arduino eeprom has a useful life of 100,000 cycles - even so, I monitor writes and change the eeprom memory location every 100,000 writes ), so if there is a power failure (shutdown) before vacuum bleeds off, the maximum error is one minute. When the engine is turned off normally (engine shutdown vacuum solenoid) the Hobbs meter value is saved to eeprom. On the display side, the Hobbs meter value was appended to the data string for the other engine instruments that are passed over bluetooth to the Android tablet in the steering wheel for display. Two of the existing 6 screens were updated to show engine elapsed time as well as a dedicated Hobbs screen.

The next step is to actually start logging the engine data by adding a microsd card to the Arduino - I've figured out how to do this, the next step is to implement it....stand by.