|

|

|

|

|

|

|

|

|

|

|

#16

|

|||

|

|||

|

My Investigation Continues

Here's what I did today in pursuit of determining the cause of my high idle:

- rechecked all points in the vacuum network where I had previously altered or removed components. All caps were present and snug. - scrutinized my in-dash Economy gauge while idling (at 1500 rpm). The needle was pegged to the minimum. - hooked up a vacuum gauge at the driver's side firewall junction. While warmed up and idling, I read 21 in/Hg or about 0.7 bar. The service manual specs 0.585 bar. - disconnected the throttle linkage to see if it would "relax" further toward the closed position...it didn't, and when reconnected there was a decent amount of spring force being applied to the linkage - lubricated the throttle linkage joints with ATF - rechecked the electrical properties of the Idle Speed Air Valve (ISAV) "Y6": this time I read a different resistance (4.8 Ohms) across the two pins versus last time (4.3) and very different operating voltages (4.8 versus 3.2, which I understand will vary under operating conditions...but it still seemed suspect to me). - noted that my ISAV had a date-looking stamp of "31/96", which suggests that the original was replaced after 10 years in service, and this one's been at it for around 12. EDIT: This is an incorrect assumption since the new part could have been installed at any time after its manufacture, so its time-in-service is just speculation. - here's where some pictures are in order (please excuse the filth)...    This is where the Throttle Valve Switch (TVS) connector identified as "S 29/2" lives on my '86 560SL. The TVS itself is attached to the driver's side of the throttle body, which is buried beneath the intake manifold, air meter and fuel distributor...basically inaccessible.    With the valve cover breather hose removed and S29/2 disconnected, I revealed the male side of the junction, with its convenient labels identifying the three pins. Referencing the service manual page titled "Checking, renewing throttle valve switch" (07.3-152), I measured the continuity between pins 1 and 2 with the throttle resting in the relaxed/idle/closed position...and read an open circuit (no Ohms home). With the throttle held fully open, I also measured no Ohms across pins 2 and 3. According to the test, my TVS is bad in both its functions. But I wanted to see how this gizmo would affect my idle if it were working properly, so...    ...I carefully jumpered pins 1 and 2 (on the female plug) with a short piece of wire while the engine was idling. The idle quickly dropped from 1500 to 1200 rpm as indicated by the in-dash tachometer. That's better, but not the desired 600-750 suggested by 07.3-112 "Testing electronic idle speed control". Also, the vacuum dropped at bit to 20.5 in/Hg and the voltage across the pins of the ISAV fell to 4.18 volts, which seems contradictory. As a result of these tests, I've decided to replace both the ISAV and the TVS. The TVS looks to be a big job, requiring the removal of a lot a parts to reach it. Any other "while I'm in there" tasks (besides replacing the vacuum rubber connectors in the vicinity) that I should do? Also, how accurate is the in-dash tach? Should I hook up my dedicated Dwell/Tach meter to diagnostic port 3 (as suggested elsewhere) instead? Does running the engine without the air filter on affect the idle speed significantly? Can you 560 owners out there chime in with your real-world idle speeds (warm, in Park, no A/C)? Thanks for any and all suggestions! BBB Last edited by BabyBlueBenz; 02-15-2009 at 09:50 PM. Reason: image url change |

|

#17

|

|||

|

|||

|

ISAV Dissected

Resigned to replacing my Idle Speed Air Valve (ISAV), I tried to take it apart to understand its inner workings and see how it might be adjustable, as mentioned by dpetryk:

Four hacksawing episodes later, and it still didn't fully come apart.  It's a well-built little gadget. My only useful observation was that the plunger-valve was dirtier than I expected after cleaning it with nearly a full can of Brakleen three weeks ago. Before I sawed it apart, I connected the ISAV with some spare wires to my model railroad transformer, which outputs up to 14 volts with no load. When connected up, it took "full throttle" on the transformer to fully close the ISAV plunger. My VOM indicated 4.6 volts. This may be a totally incorrect method for testing the ISAV, but I wasn't impressed by the results...so, out came the hacksaw.  As for adjustability, I did see a threaded insert underneath the plastic cap (upper left in photo). This probably adjusts the spring seat and its force, but I could figure out how to move it. Last edited by BabyBlueBenz; 02-15-2009 at 09:51 PM. Reason: image url change |

|

#18

|

||||

|

||||

|

Here is the adjustment. - You move it inward to increase the idle speed and pull it out to reduce the idle speed. When moving it make small movements. I use a flat tip screwdriver to pry between the nut and the housing to pull it out. I use a vise to push it in. The screw is a 10-32. It is not the right thread but it will hold. I do not screw it too tight for fear of trashing the threads inside the brass thing in the valve. I just make it hand tight but be sure it is seated. I could not find the proper screw to fit it. The 10-32 works great for me. Remember just small adjustments.

__________________

I got too many cars!! Insurance eats me alive. Dave 78 Corvette Stingray - 3k 82 242 Turbo Volvo - Manual - 270k 86 300e 5 speed manual - 210k 87 420sel - 240k 89 560sl - 78k 91 420sel - 205k 91 560sel - 85k 94 GMC Suburban - 90k 97 Harley Davidson Heritage Softail - 25k 00 GMC Silverado 1 ton 30k Last edited by dpetryk; 02-09-2009 at 10:45 AM. |

|

#19

|

||||

|

||||

|

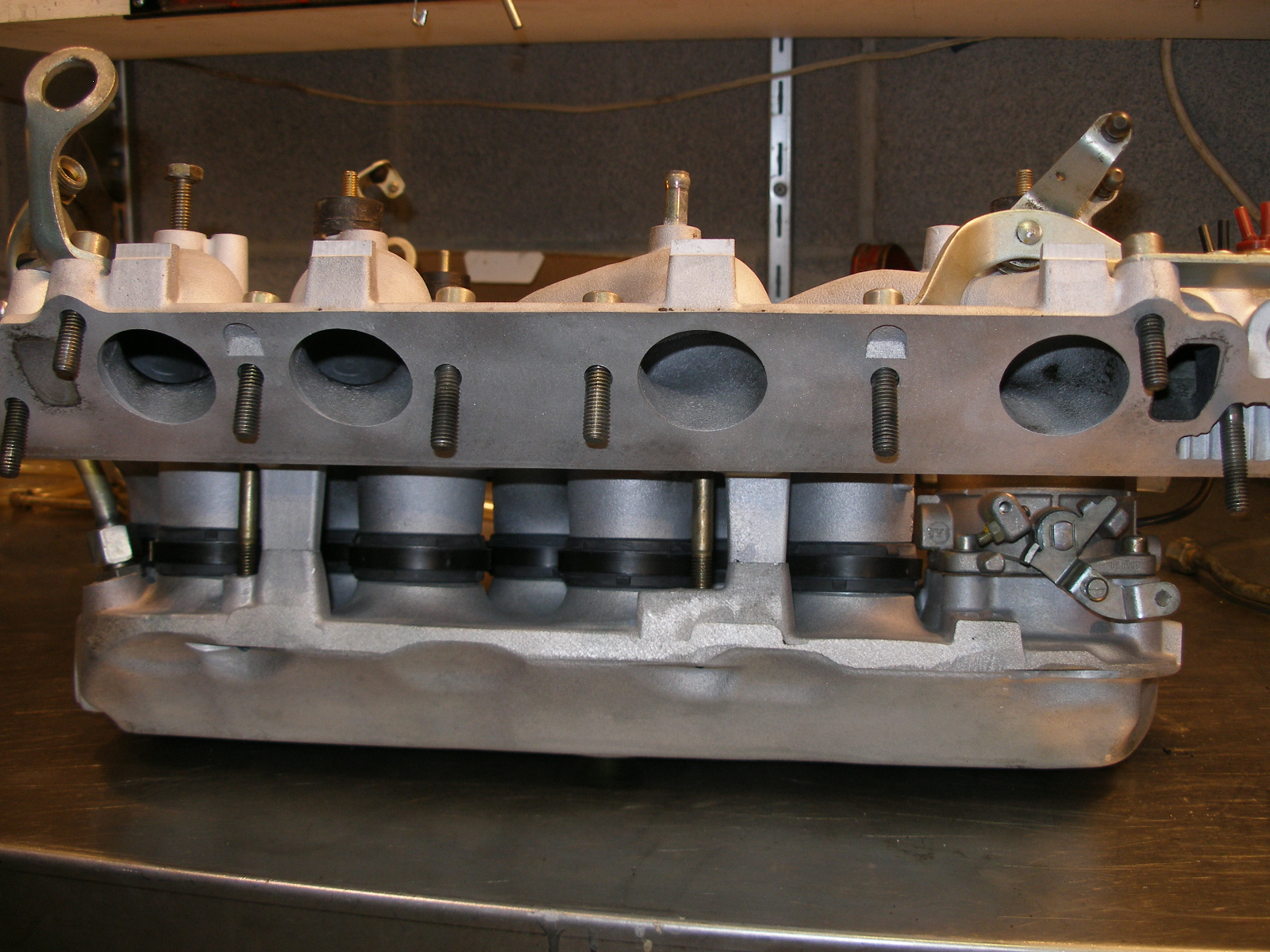

BabyBlue, while you are in there you want to replace all the rubber donuts between the manifold halves because these harden up over time and leak causing a high idle condition. Also any other seals that are exposed to vacuum.

__________________

I got too many cars!! Insurance eats me alive. Dave 78 Corvette Stingray - 3k 82 242 Turbo Volvo - Manual - 270k 86 300e 5 speed manual - 210k 87 420sel - 240k 89 560sl - 78k 91 420sel - 205k 91 560sel - 85k 94 GMC Suburban - 90k 97 Harley Davidson Heritage Softail - 25k 00 GMC Silverado 1 ton 30k Last edited by dpetryk; 02-09-2009 at 10:47 AM. |

|

#20

|

||||

|

||||

|

My idle speeds are 700 in neutral and 650 in drive. On all my cars.

__________________

I got too many cars!! Insurance eats me alive. Dave 78 Corvette Stingray - 3k 82 242 Turbo Volvo - Manual - 270k 86 300e 5 speed manual - 210k 87 420sel - 240k 89 560sl - 78k 91 420sel - 205k 91 560sel - 85k 94 GMC Suburban - 90k 97 Harley Davidson Heritage Softail - 25k 00 GMC Silverado 1 ton 30k |

|

#21

|

|||

|

|||

|

Oh My

Thanks for the great pictures and your idle speeds, Dave. That's an interesting approach on adjusting the ISAV. I concur with your suggestion regarding making small adjustments to it. Observing my ISAV with power applied, I saw little more than a 1/4 inch in its range of motion.

I didn't expect to have to take off the intake manifold to get at the throttle!  The service manual pages indicate that just the Mixture Control Unit with Air Guide need be removed (07.3-225) as a prerequisite to removing the Throttle Assembly...and I don't really want to remove that unless its necessary. The service manual pages indicate that just the Mixture Control Unit with Air Guide need be removed (07.3-225) as a prerequisite to removing the Throttle Assembly...and I don't really want to remove that unless its necessary.If I have to break the coolant system open, then I'm in Timing Chain & Guides replacement territory. I was nervous enough just considering disconnecting all those wires and fuel lines to access my faulty switch. Is there not enough room to reach the Throttle Valve Switch with one of these?

Last edited by BabyBlueBenz; 02-15-2009 at 10:09 PM. Reason: image url change |

|

#22

|

||||

|

||||

|

I'm sure you are right - you don't have to remove the manifold to get to the switch. I had a lot of nasty residues and some liquid on the bottom half of the intake manifold so I decided to clean up everything. Garbage tends to collect in these types of "uphill" manifolds. I was fighting vacuum leaks and I wanted to be sure I replaced all the potential sites for leakage.

__________________

I got too many cars!! Insurance eats me alive. Dave 78 Corvette Stingray - 3k 82 242 Turbo Volvo - Manual - 270k 86 300e 5 speed manual - 210k 87 420sel - 240k 89 560sl - 78k 91 420sel - 205k 91 560sel - 85k 94 GMC Suburban - 90k 97 Harley Davidson Heritage Softail - 25k 00 GMC Silverado 1 ton 30k |

|

#23

|

|||

|

|||

|

I have tried twice, both times unsuccessfully to get the switch out with the throttle valve on the manifold. It's not that big of a deal to remove the air guide, except that you really need some force to get the collar off the throttle valve neck. Once you've done that, the throttle valve comes off easily. Be sure to check the air guide for cracks, and you may want to replace the band and lock that holds the collar to the throttle, as well as the vacuum line connectors.

Since you've got the injection mostly undone, this would be a good time to do the injector seals as well. Cheap.

__________________

Chuck Taylor Falls Church VA '66 200, '66 230SL, '96 SL500. Sold: '81 380SL, '86 300E, '72 250C, '95 C220, 3 '84 280SL's '90 420SEL, '72 280SE, '73 280C, '78 280SE, '70 280SL, '77 450SL, '85 380SL, '87 560SL, '85 380SL, '72 350SL, '96 S500 Coupe |

|

#24

|

|||

|

|||

|

Parts Progress

I received a new Idle Speed Air Valve and Throttle Valve Switch (TVS) today. I will probably just install the ISAV first and see how she responds to that and bypassing the currently faulty TVS' idle signal. Then I'll (delicately) tear apart the top side to gain access to the throttle assembly and replace the TVS.

Based on the helpful advice above, I'll order the injector insulating sleeves & o-rings. I've already got fresh rubber vacuum elbows for those connections at the throttle body. 2/14 UPDATE: I replaced the ISAV and started her up. No significant change to idle...unless I bypass the faulty TVS by jumpering its connection pins #1 & 2. Then the idle drops nicely...but still indicated on the tachometer as over 1000 rpm. Not great, but an improvement. I went ahead and pulled off the Mixture Control Unit and Air Guide as an assembly to gain access to the throttle. As mentioned by another, it wasn't too hard (except for separating the Air Guide throat from the throttle). The next step will be to see if I can reach the two TVS screws with the throttle still on the engine, or whether the throttle has to be removed first. I'm semi-documenting this operation, in case others would like it outlined. See The 560SL Throttle Valve Switch Replacement Narrative. Last edited by BabyBlueBenz; 02-24-2009 at 10:42 PM. Reason: Updated (Thrice) |

|

#25

|

|||

|

|||

|

I had the same problem with my '84 500sl. I removed the idle control valve and cleaned it with a product called " Gun Scrubber" it can be found at any Wal-Mart or similar store.

The black gunk ran out of it for what I thought was a long time. but when I reinstalled it everything was fine again. It has only been a few days but (knock on wood) no problems so far. I adopted the attitude that if a little was good a lot was great and used most of a can. However it is cheap in comparision about $6.00. Worth a try and it sure runs the black out. Good luck Tiehacker |

|

#26

|

|||

|

|||

|

Replaced TVS

Quote:

ctaylor738, the big hose clamp holding the Air Guide throat onto the throttle body broke the moment I tried to tighten it. I can't identify this part or find it on a cursory search at Fastlane, ******** or PerformanceParts...any suggestions on a source? I'm starting to look for a generic hose clamp equipped with a side-ways screw setup. Last edited by BabyBlueBenz; 02-23-2009 at 12:39 AM. Reason: New thread referenced |

|

#27

|

|||

|

|||

|

You can get the parts from a dealer or Phil should be able to find them for you. There are actually two pieces, the band and the lock, best to replace both, since it's very easy for false air to enter the system at that joint. I would look up the PNs but the EPC is down at the moment. I will try again later.

You did check the air guide very carefully for cracks?

__________________

Chuck Taylor Falls Church VA '66 200, '66 230SL, '96 SL500. Sold: '81 380SL, '86 300E, '72 250C, '95 C220, 3 '84 280SL's '90 420SEL, '72 280SE, '73 280C, '78 280SE, '70 280SL, '77 450SL, '85 380SL, '87 560SL, '85 380SL, '72 350SL, '96 S500 Coupe |

|

#28

|

||||

|

||||

|

Mine did the same thing, but it wasn't broke, the pieces just separated. It took a bit of figuring out and several attempts to put the pieces together again correctly, but eventually they came together and worked just fine. Patients was the key. I had also though about replacing it with a standard metal band hose clamp, but the access to get a screwdiver in a horizontal position to tighten the screw was virtually impossible.

__________________

Question Authority before it Questions you. |

|

#29

|

||||

|

||||

|

Quote:

Great pics. I'm fairly convinced that is the cause of my high Idle hell as everything else has been addressed. Come some warmer weather, that's my next project.

__________________

Question Authority before it Questions you. |

|

#30

|

|||

|

|||

|

Quote:

Quote:

Quote:

I gave it a good look, but nothing jumped out at me. I'll be checking it again soon...any particular areas to look for cracking? The edges? The folds? The throat where it's clamped? I'm also considering doing the full intake manifold removal to clean up the gunk accumulated on the bottom plenum and replace those Manifold Seal Rings (aka rubber donuts). I recently bought one new one to compare its softness to those on the car...and they're quite hard. [Sigh] My To Do List isn't getting any shorter. Last edited by BabyBlueBenz; 02-23-2009 at 09:45 PM. |

|

| Bookmarks |

|

|