Engine Mount Replacement

on the 1997 E300TD (W210 OM606)

by Parrot of Doom

11/29/06

How to change OM606 engine mounts

At 176,000 miles the engine mounts could do with changing. The car shakes slightly when the engine is killed, and the steering wheel vibrates gently when idling. Not things a Merc should do. Job should take about 2 hours, no more.

First let me begin by pointing out that this is a RHD turboed car. There will be differences for obvious reasons!

Tools required:

- Ramps

- Scissor jack (or trolley jack but scissor is easier)

- Big blocks of wood, railway sleeper thickness

- Sockets, ratchets, extensions including a flexible extension

1) Put the car on the ramps, parking brake on, gearbox in P. Chock the rear wheels.

2) Remove the 2 plastic trays protecting the engine, and the transmission. 8mm bolts.

3) The mounts are easily spotted. They're also quite accessible.

4) Each mount is held to the chassis by two bolts. One on top, one below. The bolts below are a doddle to reach, holes have been cut in the chassis to allow a socket through. Its the bolts on the topside that are a bit tricky, however they're not too difficult.

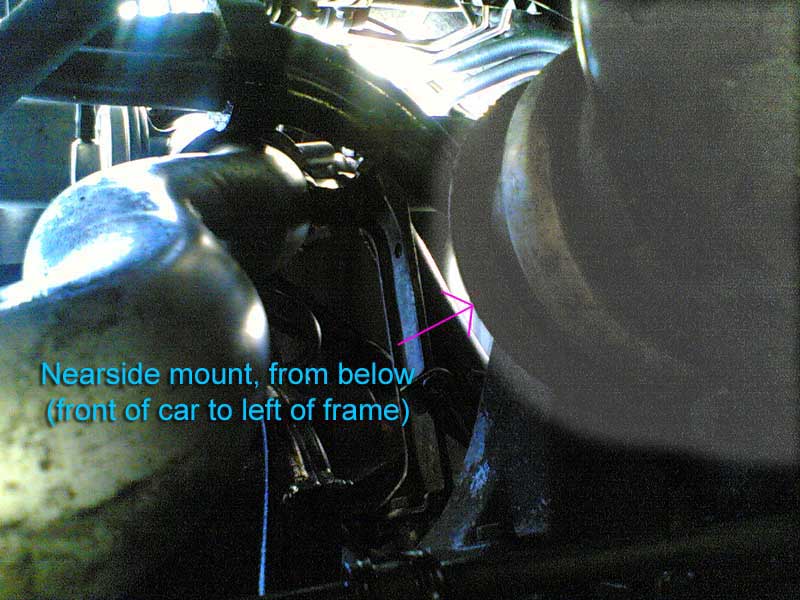

These images show the location of the mounts, from underneath the car, and the location of the bolt on the nearside mount.

You can see how easily accessible it is. Unfortunately, the top bolt isn't quite so obvious. You have to reach around with a spanner and undo it blind - unless you remove the intake manifold, which is job for another day really. Fortunately, the offside mount top bolt was barely fingertight so not an issue.

Just like removing a wheel, its important to loosen both bolts before you jack the engine up - this makes removing the bolts much easier before you place massive strain on the engine by jacking it.

5) Move your scissor jack into position underneath the oil pan, and carefully raise it up. If required, put a block of wood underneath the jack to get the necessary height.

You will need to put a block of wood between the oil pan and the jack, to spread the load over a wider area. You don't want the jack punching through the oil pan, or distorting it in any way. Wood is nice and soft, so is ideal for this.

MAKE ABSOLUTELY CERTAIN THAT EVERYTHING IS SECURE AND WON'T MOVE AROUND BEFORE YOU JACK THE ENGINE UP

6) Jack the engine up about 1/2 to 1 inch - no more should be necessary. Now, go to the nearside mount, unscrew the remainder of the bolts top and bottom, and it should come out straight away. They don't weigh much, but don't let it drop on your head!

If you look at the top rubber sections, you might be able to make out a large crack running around the circumference of the mount. You can also see the top locating pin.

Here are the old and new mounts together. Note the difference in height - I'm uncertain if this is wear/tear, or different design. Probably a combination of the two. Certainly the engine mount I bought (MB OEM) was different in several ways, most obviously the use of more rubber (not visible in the pic)

7) Pop the new mount in place. You may have to jack the engine up slightly, as the new mount will be slightly taller than the old one. Be careful not to push it up too far, keep an eye on the fanblades and exhaust. Ensure that the top locating pin fits correctly into the mounting area, and screw both bolts in place. Lower the jack slightly and let the mounts take the weight of the engine, and tighten both bolts up securely.

Let the jack down completely, and for good measure give the bolts another bit of a nip.

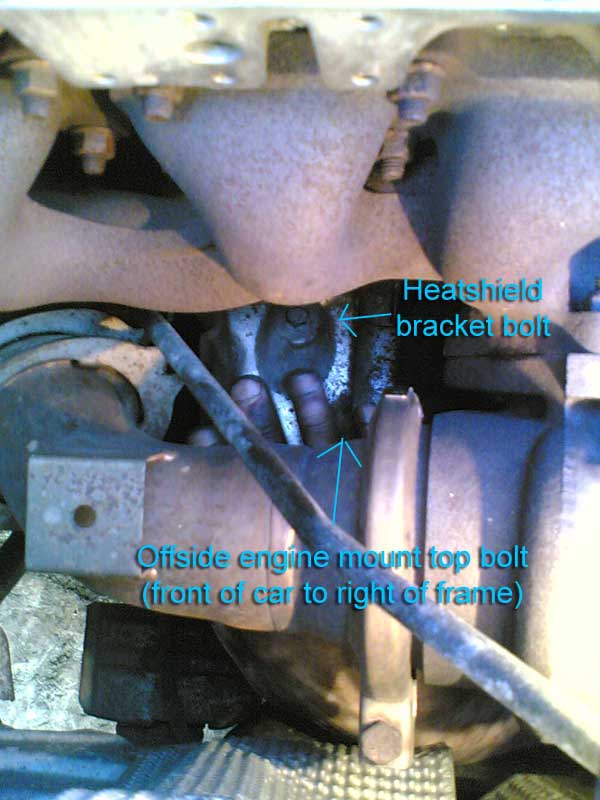

8) The offside mount is a bit easier. The bottom bolt is just as simple to remove as the nearside mount. The top of the mount is different. A metal bracket holds the exhaust heatshield in place, and the bolt for the mount passes through this bracket. In this picture, you can see the bracket, the bolt that holds the bracket, and just underneath my mate's fingers is the top bolt for the mount. The tube running diagonally through the frame is the gearbox dipstick tube.

You don't need to remove the bracket to get the mount off, so leave that alone. You will need a flexible fitting for your ratchet, like this:

The cloth is optional!

Loosen both bolts, and jack the engine up again, remove the bolts, and pull the mount out.

Now I found something very curious here. Each mount has a different part number. The two new mounts that I bought, one had splines on the base, the other had a smooth base. Yet as you can see here, both old mounts had splines on the bases. The splines appear to do nothing, the locating elements of the base are the 4 dowel sized indentations on each mount.

Theres a bit of crud on one of them that looks like a pin, its not, its just crud.

I have no idea if theres any difference - I think 99% not. I think the part numbers are kept different for book-keeping purposes. Both mounts were absolutely identical in every respect. There were no issues whatsoever with the new mount with a smooth base. I think its just one of those things. If anybody knows otherwise, please let me know on this thread, or here:

http://www.peachparts.com/shopforum/showthread.php?t=171144

And there you have it. Pretty easy job. A couple of times while out driving I thought the engine had stalled. The steering wheel previously vibrated slightly, now its a barely noticeable murmour at idle.

Hopefully now I can get the belt tensioner problem sorted finally!

For future reference, I have found some stock images of the two shocks.

Left (offside) mount:

Right (nearside) mount:

Discuss this DIY here.

-Parrot of Doom

CategoryDiy