Auto to Manual Climate Control Conversion

on the 1978 300CD (W123)

by gavin leslie

10/23/08

300CD ACC to 240D manual climate control conversion

Alternate title: Ur doing it wrong

I would have posted this while I was in the process of doing it, but I was a bit unsure that it would all work (especially since I was working without a manual). About half way through I started to feel more confident that this procedure was going to work and so, Ive decided to make a writeup of what I did to get to this point.

Why was I unsure that this was going to work? I did this the hard way.

I had read previous posts from "Bruce Kennedy" that he had done this conversion with success. In this he states that the easiest way to convert the climate control system is to pull the entire heater/evap box and swap them. This is correct. This is the best/smartest way to do this conversion……..but Im not that smart so I did this the really hard way and collected the individual bits and pieces needed to do the conversion.

Again, I urge anyone attempting to do this conversion to swap the heater/evap box wholesale. Less headaches, quicker, less fabrication, etc, etc. But where is the entertainment value in that?

A very thorough guide to removing the heater/evap box can be found here by dmorrison. This should guide you through the major steps for the climate control conversion.

Since I did this the stupid-tastic way, it does occur to me that I can point out the areas of contention with both systems and the way I tackled them. So here we go.

The car in question is a 1978 300CD using the oh-so wonderful ACCII system. I think the words “engineered to fail†sum up this system. Hindsight is always 20/20, but how Chrysler thought that coolant, vacuum and electricity would coexist in a little R2-D2 unit is beyond me. At one point there was a severe short that would drain the battery. The short was traced to the servo...solution? Disconnect the servo. This I didn’t like because now the girlfriend was without heat. I replaced the cracked plastic servo with an aluminum bodied servo and got a working auxiliary water pump. For a while there was heat to be had, but only using the defrost function

And then, inexplicably….it stopped blowing heat. Arrrrrgh!

At this point I decided enough is enough. Id had it with the stupid servo and the nightmarish vacuum setup. Winter is on its way again and, while this is California, heat is very useful. It had to go, it was time to take the plunge with the conversion.

The local junkyard tends to have a healthy selection of W123s. At any one time you can probably find 5-7 cars. Sure enough a W123 brown/brown (sorry I don’t know the specific paint/interior color code nomenclature) 240d automatic with a door plaque that said “sept 1977†was there. It was in great shape actually…not really sure why it was there. The interior was intact and it looked like I was one of the first people to touch it. I pulled everything that I could from it….except the heater/evap box.

Naturally the first thing that would help for the conversion is to get a donor car that’s close to the year/generation of the car that you have. Both the donor and the transplant cars were “1978†cars. I imagine wiring diagrams and the like are much closer in the 1978-1980 cars, same for the 1980-85 cars.

Here we have the pieces that you would need (if you were as silly as I was and just got the individual parts).

-Bowden cables(four altogether)

-heater valve and hoses

-A/C switch panel

-heater/fan switch panel (not shown)

-240d fresh air/fan vacuum actuator (not shown)

-heater/fan panel fascia

-manual coolant pipe from the engine block

-center vent slide mechanism

-the zip-loc bag has assorted jam nuts, knobs, clips for the Bowden cables, etc

-240d A/C / fan wiring harness (two pieces, not shown)

PS: be very careful when disconnecting the Bowden cables from the plastic levers. Depending on how the plastic has aged it could be brittle. Its very easy to add too much muscle and snap the levers. Take your time, take it easy. It would be a shame to break one of those levers just because you got impatient.

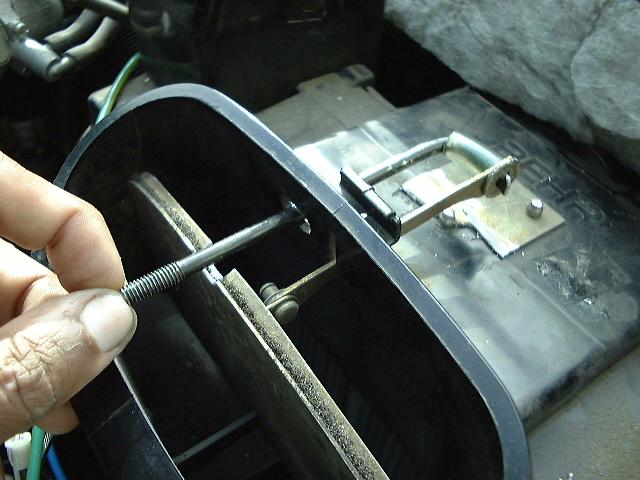

Here's a picture of something important.. these are a couple levers and brackets that NEED to be removed and transferred. No problem right?…Well, heres the thing. The lever to the left can be popped out somewhat easily with a bit of patience but the other lever to the far right is welded onto the shaft. The brackets are riveted on. I have a mini dremmel that I tend to take with me to the yards, but you can see that this is a big pain.

PS: the main heat/fan switch panel on the 240d is riveted to the heater/evap box instead of screwed/bolted on like the auto control switch panel. Mercedes loves rivets. Perhaps you see why I say that its ultimately better to just swap the whole thing…if you still don’t, Ill show you some more fun things.

So, provided you have all the pieces, heres what yuoll have to do to get things going.

-Drain the coolant and remove the dash (already mentioned in the above link).

-Remove the vacuum lines going to the servo and associated hardware. NOTE: you will only need to keep 2 vacuum actuators. The one above the blower fan and the one behind the heater/evap box that works the vents to the rear of the car. Everything else can go.

-Remove the wiring harness for the HVAC/servo system. This is somewhat easy as its all one piece. It starts at the grounds that are in a bundle in the forward passenger front fender and goes all around the car to an inline fuse in the relay box and a connector for a temp probe in the firewall. Between that there are assorted plugs that need to be disconnected, a single ground connected to the steering wheel support, power from the fusebox(#12 connector for the fan). The whole mess comes right out.

-remove ACC servo and assorted hardware(brackets, piping, aux water pump)

In the end, you will have this mess…

In case you weren’t sure of what it looked like, Ive pointed out the ACC servo for you. No need to thank me

The easy parts of the install will be installing the heater valve, the coolant pipe that feeds it and the Bowden cables that actuate the valve. These are all plug and play.

A couple small notes though. The Bowden cables need the grommets and small spacers that seal the bulkhead. I had forgotten those and had to source new ones at the hardware store. The bowden cables are affixed by “C†clips. You will need a tool for them as well. The heater box is fed through 3 ports, the heater valve takes care of two. The one remaining port on the drivers side will be fed by the existing heater tube that had previously fed the lines to the ACC servo. Even though it has a slight bend in it, there is enough flex and slack that it lines up with that remaining heater box tube very well.

This cable and lever go to the fan controls. The lever needs to be changed from the vacuum actuator to the manual cable lever. The cable mount needs to be added as well. There are two rivets in the place where the mount would be affixed. I couldn’t get to those rivets to remove them and reuse the holes, so what I did was to make a new hole under the heater box and add a rivet there. For additional support I added a brace and riveted that to the heater box as well.

This vacuum actuator was swapped from the 240D. It’s a pretty cool and burly unit. Mainly I swapped it and its mount because it actually held vacuum (and the ports line up with the A/C dial/controller). I removed the old vacuum pod and its mount. There are placeholder rivets where the new mount should be located. I drilled those out and riveted the new mount in place. Theres also a small clip that connects the actuator rod to the flap, don’t forget to get that as well.

To the left you see the cable for the slide actuator for the floor/dash vents and its mount. The mount is pretty easy, remove existing rivets and rivet the cable mount in their place. The lever that actuates the vents is interesting. On the 240d its welded on to the shaft. I ground down the weld and removed it from the shaft it was on. Its keyed in a “D†shape so it can hold to the shaft. I used the old spacer (also keyed with a “Dâ€) and press fit the new lever onto the shaft. Its then fixed there with doubled up clamping washers. The return spring is also a transferred item from the 240D. Between the cable mount and lever arm (a little south) are two rivets with their heads drilled off. This was where the mount for the old wiring harness was located. It needs to be removed so everything in this area fits.

On the left side of the heater box was the old vacuum pod and lever arm for the floor/dash vents. There was normally a plastic shroud to protect the wiring harnesses from the lever and its movement(so it doesn’t try to cut the wires), but when the new levers/cables were added its range of motion interfered with the shroud and limited the vents movement, so the shroud was removed and the lever arm cut. The vacuum pod was also removed

First picture is of the switch panel mounted. You cant see it here, but the rivet holes (remember it was riveted to the heater box) on the bottom needed to be enlarged. The auto climate panel has a stepped mount and a raised and threaded screw insert. The new panel needs to fit over that threaded insert to mount flush on the heater box. Some appropriately sized washers corrected the height difference and the new panel was bolted back on.

Second picture is of the vacuum lines going to the A/C control. Top left is the main vacuum feed from the engine bay. The two on the right go to the vacuum pod over the blower fan. The bottom left tube(blue) is spliced into another tube. That tube feeds the vacuum pod for the floor vents. In the 240D that pod is on the right side of things. In the 300CD its on the left. I needed to add a bit of length to the vacuum line to get things connected.

Picture of the vacuum pod in question.

Wiring harness!!

It’s a two piece deal. On the right is the section that connects to the fan control switch. The other end of it is a four pronged dongle. In the middle are two grounds (to go to the steering wheel mount), one black(pink/green) wire (that will go to the #12 terminal of the fuse box) and one white/blue wire that gets connected to the 16(?) prong connector that to the back of the gauge cluster (wired to the #12 prong). I think this goes to the dimmer(?)

The wiring harness on the left connects to the fan, the receiver for the four prong dongle thingie, the resistor pack for the fan and a single black(red/green) wire that goes to the A/C thermoswitch (Make a note of this for later).

The old fan connector on the 240D were blade type connectors. The connector for the 300CDs fan is a standard familiar keyed male connector. I rewired it to accept the female half for that connector.

The lights and connectors for the dials were actually on two separate wiring harnesses in the 240D and not on the blower fan wiring harness. I cut them off and then rewired them into a new single wiring harness with an extra connector from the speakers so they would be disconnected separately.

I had converted the 300CD to a manual 4-speed transmission from another 240D. The auto transmission had a light that lit the selector gate for the auto shifter. Since there was no place for this with the manual shifter, the light went unused. I now needed a power source for the mini lighting harness and this is where I tapped into for power.

These are the harnesses for the blower fan resistors. Theres a bit of difference between the two as you can see. The 300CD is a 4 or 5-speed fan (maybe, I never got the thing to work so who knows) with a 6-pin connector. The 240D is a 4-pin connector and is a 3-speed fan system. The 240Ds harness also has the plug go directly to the fan whereas the 300CD the plug is on the main harness of the servo system. The 240D also has one half of the connectors for the A/C receiver-drier (ill get to this in a bit). I simply swapped over the 240Ds wiring harness. I could have done a bit of resistance testing and rewire things, but it was easier to pull the heater/evap box a bit forward to swap the harnesses.

The center vent was kind of a head scratcher.

The center vent in the 240D is located further back on the top of the heater/evap box than the 300CD. Its also actuated by a slide lever and bellcrank system that converts left/right motion to in/out and then finally up/down to open the center vent like a trap door. It’s a pretty clever setup. The 300CDs vent is (as mentioned) closer to the front and is actuated by a vacuum pod (in/out motion opens trap door up/down).

Because of the difference in location. The linkages wouldnt work as everthing was on top of each other. I couldnt swap the vent doors either as they are specific to their respective boxes. Another solution had to be found.

What I came up with was the setup you see above. I pulled the vacuum pod and kept the actuator rod. Then I straightened the manual slide lever actuator rod(had a 40-ish deg bend in it), cut off the clevis at the end and bent the last ¾†90deg. I cut a new hole for the new revised actuator rod and clearanced the vent flap a bit for it. Finally I cut a small hole in the vents rubber boot so the new actuator rod could pass back and forth through it. After a bit of trial and error with cutting the hole in the rubber boot (I didn’t want to make too big of a hole, just big enough) everything works as intended.

And there it is. Everything is in and the heat works perfectly. I can send heat this way or that way, its awesome! This is lightyears better than the servo driven system.

Is everything perfection though?….No, not everything works.

The two vacuum servos (top of the blower fan and back of the heater box for the rear vents) aren’t working right now. Not surprising as the doorlocks have been wonky for a bit. Before I dreaded the prospect of tracing down leaks in the vacuum system. Now with the rats nest of vacuum lines/dealios gone, things are massively simplified. I feel much more confident in tackling this minor detail now.

Air conditioning….no workie.

I had alluded to this. The system has been without charge for years and the girlfriend doesn’t seem to care much (she used to drive to the central valley of California in the summer like this), so I hadnt really made an effort to get the A/C system functional.

I don’t think there too much to do though. The 300CD has one plug for the receiver-drier and both plugs for the thermoswitch on the main servo harness. The 240D has both plugs for the receiver-drier on a separate harness and one plug for the A/C thermoswitch on the blower harness. The end result when you swap the harnesses is that the conversion leaves one connector on the receiver-drier blank and one connector on the A/C thermoswitch blank. I think this would be pretty easy to figure out what needs to be done there.

In the end, Im pleased with the results. Its already um..eleventybillion times better than the old system(for one it actually blows heat). Was this a silly way of doing this conversion? Yes. I could claim ignorance but I did see Bruce Kennedys suggestion so…yeah. Sometimes we aren’t as good as we can be. It was an error, but hopefully my mistake can be useful to others in the future.

Hopefully this is somewhat clear and I didnt miss anything big.

Cliff notes: swap the boxes.

Gavin

Discuss this DIY here.

-gavin leslie

CategoryDiy