Climate Control Vacuum Valve Repair

on the 1987 300D Turbo (W124 OM603)

by Jeremy5848

07/25/10

W124 Climate Control Vacuum Valve Repair DIY

On a recent trip to the "Pick and Pull" DIY auto scrapyard at Windsor here in northern California I discovered a new climate control failure mode (as if there weren't enough already). I had decided to pick up an extra vacuum control valve for my 1987 300D Turbo (W124, OM603). This thing, which Mercedes calls "Y7 Switch-over Valve Unit," controls the vacuum to all of the pods that open and close the various 'doors.' Where the 123 has individual valves, the 124 has a set of seven valves built into a vacuum manifold and mounted on the right (passenger) side of the air box. You can see it if you remove the glove box liner. If you have an air bag there (late 124) you must remove the right side under-dash panel.

When I got home from Pick and Pull, I tested the thing and discovered that two of the valves didn't work. I went back and exchanged it for another, only to discover a similar problem. I ended up buying a third before I found one that was completely good but decided to keep the second (they were only $6.49 each) so I could experiment. I was surprised that these things went bad -- they're so simple -- and worried that mine might be bad, too, even though my climate control seems to work correctly.

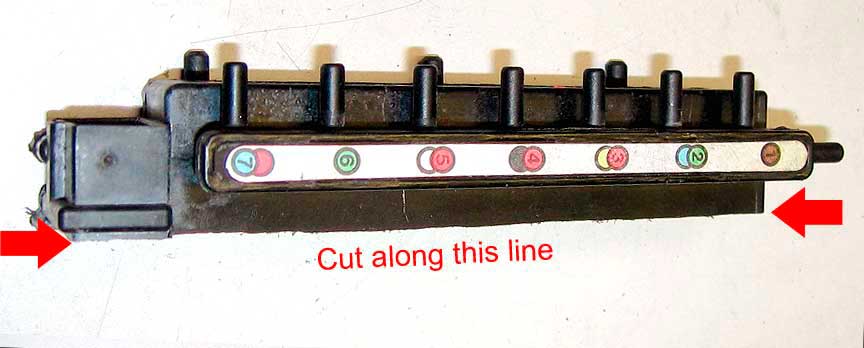

The manual tells us that these things are non-repairable and indeed the plastic case is heat-sealed together -- no cover to unscrew, very un-Mercedes-like. It was clear to me (from an examination of the 8-pin plug) that a pc board ran the length of the manifold, connecting the plug to all of the vacuum solenoids with one pin common. I immediately thought "cold solder joint" but how to get inside? I finally decided to do the job semi-destructively and cut off the back with my bandsaw.

This could also be done with a hand saw or a sabresaw but you'd have to have very steady hands. With the back off, I could see that there really was a pc board "spine" and I could test all of the connections.

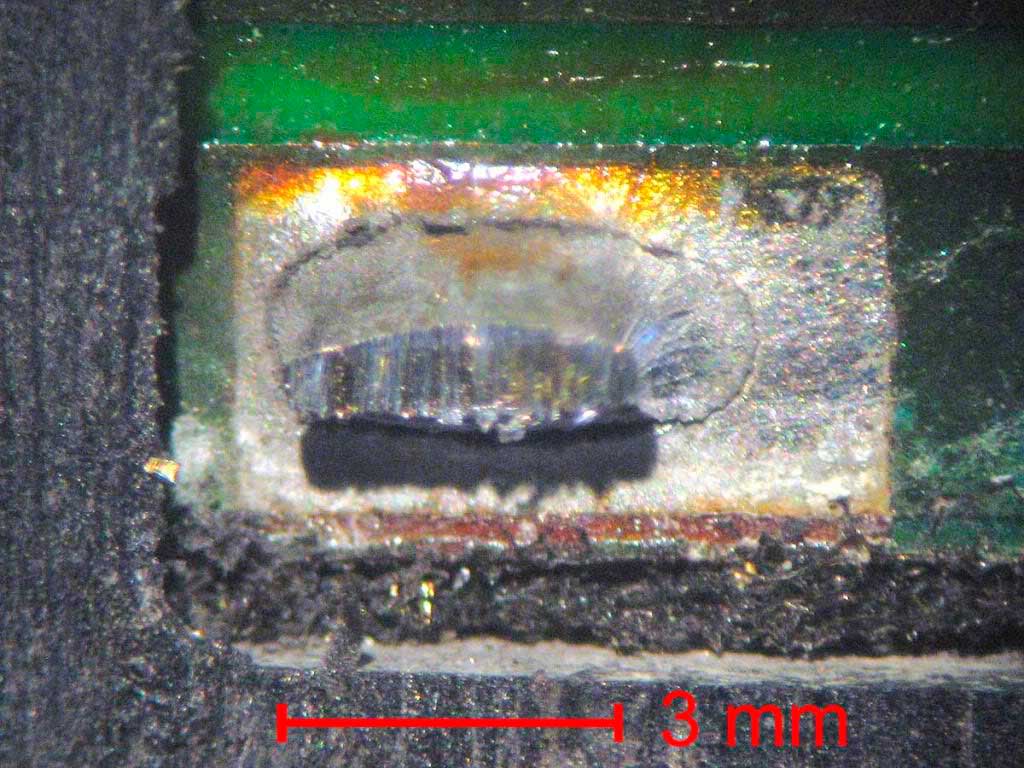

Each solenoid tested good (12 Volts across its pins and it went 'click') but as I carefully examined the connections, I saw one very obvious cold solder joint. Here is what it looks like in a low-power zoom microscope (hold digital camera up to eyepiece).

With the problem identified, it will be easy to refresh all of the solder joints. I'll then smear silicone sealer all over the plastic back and glue it back over the manifold.

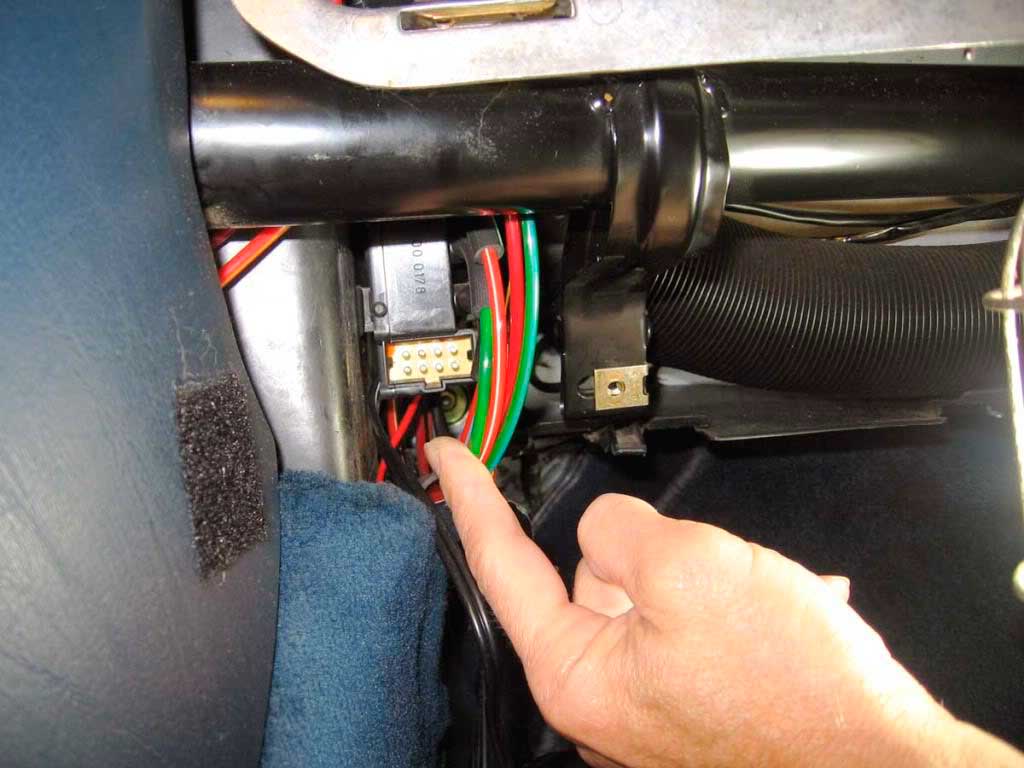

If your climate control system is not working correctly, you now know that it could be one or more of three things: a bad push-button unit, one or more bad vacuum pods, or a bad manifold. You can test the valves without removing the manifold and all the vacuum lines. This requires removing the right under-dash panel so you can get at the plug that goes into the manifold.

With the plug removed, you will see eight pins in two rows of four. One of the pins is common positive (see middle image in three-view photo above), each one of the others is the ground for one solenoid. To test the valves, connect the common pin to a 12 Volt battery (either the one in the car or a portable battery) and then touch each of the other seven pins one at a time to the other terminal of the battery. For testing it doesn't matter whether common is positive or negative. Listen closely -- each solenoid should "click" and you might get a little spark at the pin. Any pins that don't produce a "click" indicate a bad solenoid.

Again looking at the center image above, the pins are connected to the numbered solenoids in this order:

2 -- 4 -- 6 -- Common

1 -- 3 -- 5 -- 7

The solenoids do the following functions. This may help you diagnose your particular problem.

1 Fresh air/Recirculated (short stroke)

2 Fresh air/Recirculated (long stroke)

3 Diverter (no, I don't know what it does either)

4 Center dash outlets

5 Legroom outlets

6 Defroster outlet (long stroke)

7 Defroster outlet (short stroke)

A few notes: The manifold is only clipped to the side of the airbox. It pulls off fairly easily. Keep track of which vacuum line is connected to which valve (even though the label and the lines are color-coded). Be careful unplugging the electrical connector.

The alternative is to buy a new solenoid valve assembly from AllPartsExpress for $168.30. My advice: Learn to solder!

I pulled the glovebox and lower dash panel and did the acid test on the solenoid valve in my '87. Fortunately, all seven valves made a satisfying "click." Here's a picture of what the solenoid valve looks like installed in the car and with the plug unplugged. I had to scrunch down in the footwell to get the picture. Of the eight pins you can see, the one in the upper right corner is common and the other seven each go to one of the solenoids. Putting 12 Volts between the common pin and one of the others should get you a nice "click." Any one that doesn't "click" means a bad solenoid (unlikely) or a bad solder connection.

Discuss this DIY here.

-Jeremy5848

CategoryDiy