Front Strut Replacement

on the 1987 300D Turbo (W124)

by bob_98sr5

7/28/08

Following a few writeups here on the forum, I changed out my front struts. Much simpler than i thought, and no, the evil spring did not come out and bite me. Dont worry folks, the lower control arm does not pivot far enough down to allow the spring to fly off and kill you. If you want, you could always buy two sections of half inch pipe with female unions and thread it up through the spring like a bangalore torpedo!

Step 1: loosen the lugnuts

Step 2: set the e-brake, chock the rear tires.

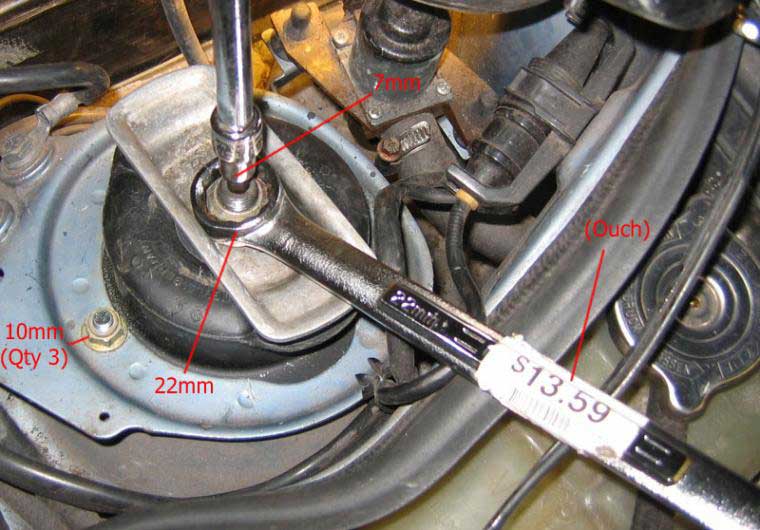

Step 3: At top of strut inside engine bay, loosen center nut w/ 22mm combo wrench and 7mm hex key socket. Loosen 10mm nuts as well (3 of them).

Step 4: Jack up by the center cross member at center.

Step 5: Place jack stands on either side of the jack for stability. Lower the jack and allow car to rest on stands. Remove the tire

Step 6: Move jack underneath lower ball joint. Jack up until the LCA begins to rise a little. Not too much because the car will lift off the jackstands.

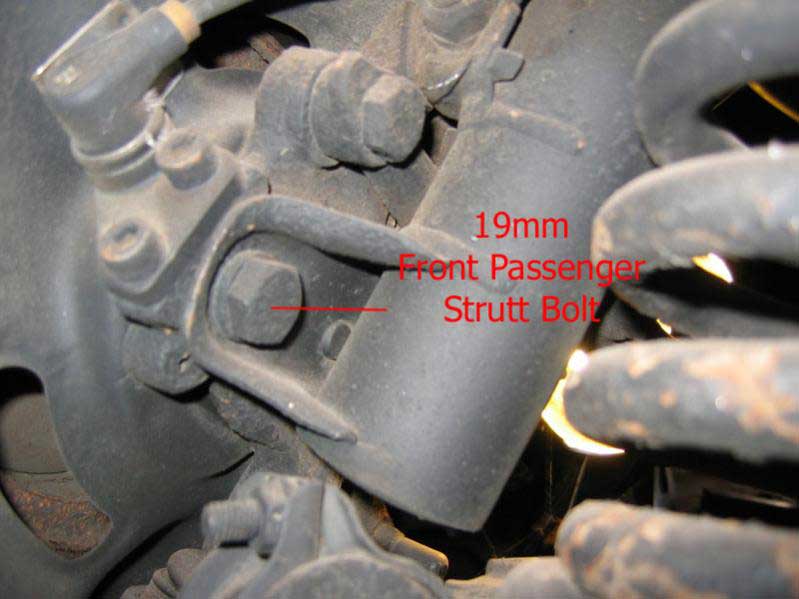

Step 7: Using a 19mm socket and a 3"-ish extension, loosen the front nut.

Step 8: Using a 19mm socket, loosen the rear nut.

Step 9: Using a 19mm combo wrench and 19mm socket (no extension), loosen top nut. Sorry, no picture.

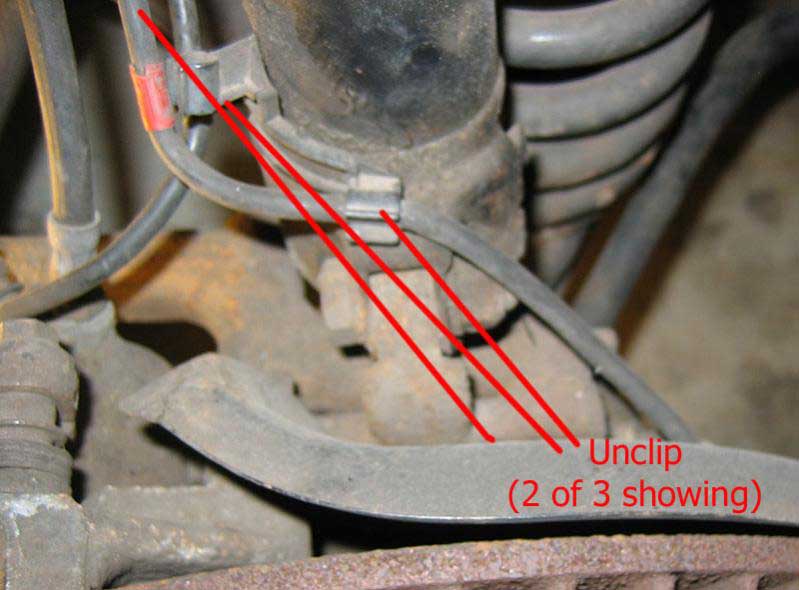

Step 10: Remove all the lines connected to the plastic piece that's connected to the lower part of the strut.

Step 11: Finish unbolting the nuts in Step 3

Step 12: Finish unbolting the nuts in Step 7 through 9

Step 13: Slowly lower the jack until the LCA is at neutral position. There should be a little tension on the jack and ball joint

enough to make sure it does not move.

Step 14: pull down on the strut mount and the strut should compress easily

at least mine did. Move to the side.

Step 15: Push the strut towards the spring. One of my struts was on there really good, so I gave it a whack with a rubber mallet. Don't hit the plastic part that holds those lines. You'll need them

Reassembly

Step 1: Remove the plastic line holder piece by pressing down on the two tabs and pushing it through. Put that piece on your new strut

Step 2: Put the rubber snubber (as I've heard these things called) onto the strut. Make sure the notches are facing upwards. Put the accordian-like shock rubber protective sleeve over it.

Step 3: Take the strut mount and push it up into the strut cup. Lightly secure with the three nuts. Of note, on the driver's side, there is a harness. Make sure to secure that one on too.

Step 4: Put the strut shaft through the strut mount and re-align the strut into place. Lightly thread on the two nuts and the nut/bolt combo. Make sure everything is aligned perfectly and then tighten down the lower nuts only.

Step 5: Push the lines back on

Step 6: Install tires and lower car

Step 7: Now that the car is resting on the tires, tighten down the upper nut and the three 10mm bolts

Sorry, I dont have torque specs. Request: someone please add them to this thread. I tightened just enough because I am having my mech put the new springs in next week.

A few notes:

- The bolts have blue loctite on them. I found them to be quite a bear to get off. I used leverage with an extension cheater bar and two came off with a bit of muscle. I learned my lesson and used a propane torch with some PB Blaster. What I did was torched them for about a good minute or two, let it cool, and then sprayed it with PBB. Then I *tightened* the bolts to break the loctite bond and then reversed and removed. Only 1 did not succumb to this method One stubborn one took two more cycles of the heat and PBB treatment

- I installed Bilstein HDs. They come with new bolts + nut/bolt combo and the top nut. Nice touch.

Misc pics:

Snubber on strut shaft. Place the strut sleeve over it and then through the strut mount

Strut ready to be installed. So shiny! You can also see the center mount point about to be mated to the mating point. This is the pic of the nut/bolt combo I missed

Tools of the trade. You'll need them if you want to make this an easy job. Don't burn any lines now!

Again, it's been written many times in other writeups about the spring coming loose if you let the LCAs down too far: no, not even close. I peered up the spring cups and there's a good 2 coils still in the cups. But again, if you're the paranoid type, buy two lengths of 1/2" pipe with female unions and thread up through the springs. Or use your coil compressor and a big arse chain.

Discuss this DIY here.

-bob_98sr5

CategoryDiy