The governor doesn't work on the intake manifold vacuum, but on the vacuum created by means of a venturi below the air valve. The air valve determines the air flowing through the venturi.

The rod doesn't control the IP, but only the poppet cam of the auxiliary mechanical governor.

My guess is that you have disconnected the air hose, but the diaphragm might be torn too. The control rod inside the IP can be stuck too.

Below is a recent write-up I did in a similar topic on Benzworld about the pneumatic governor, which might give you insight in how it works. Do read the more elaborate topic and the FSM if you want to know more. If you are going to overhaul the governor, you have to follow all the steps in the FSM.

The fuel enrichment is only done by means of the starter knob, when you pull the knob during starting, it pulls the control rod of the IP in the starting position, i.e. even more than full load.

{quote}

the injection pump has a so-called pneumatic governor. The governor is responsible for the amount of diesel injected into the engine, that determines (together with the load on the engine) the speed of the engine. It is very easy for diesel engines to overspeed, that is why there is a governor. The governor makes it possible for the engine to idle at a constant low speed and not to overspeed (more than 4400-5400 rpm).

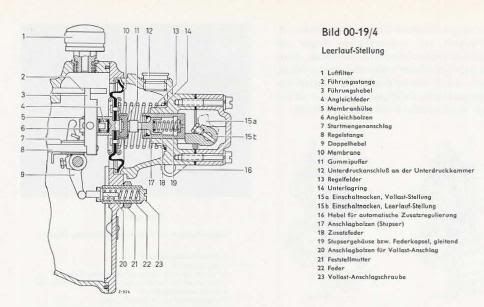

The pneumatic governor works by means of a vacuum created by a venturi in the intake manifold. A butterfly air valve (see picture below) determines the amount of air flowing through the venturi, i.e. more of less vacuum. The valve is controlled by your foot pressing on the accelerator pedal. The vacuum is "transfered" to the vacuum chamber of governor by means of an air hose. That is why there is an air hose running from the intake manifold to your IP.

Butterfly air valve in the intake manifold with venturi at the bottom.

The amount of diesel injected into the engine (and therefore the speed of the engine) is controlled by the control rod. The control rod is connected to a diaphragm. A spring pushes against the diaphragm, so that the control rod is pushed into the maximum position. The vacuum works on the diaphragm, so that it is pulled back against the spring pressure (in fact the air pressure on the other side of the diaphragm pushes against the diaphragm). So the variable vacuum created by the venturi in the intake manifold determines the amount of diesel injected.

This system works for the higher speeds of the engine, but at lower speeds and at idle the engine will fluctuate in speed ("sawing" of the engine). Therefore an auxilliary mechanical governor is installed, so that the control rod rests against a spring stop. That mechanical governor is brought into action by a rod, running from the intake manifold, over the valve cover and to the side of the IP. The rod turns a poppet cam into position. When the accelerator pedal is pressed deep enough, the poppet cam moves away and the governor purely works on vacuum.

Picture of a IP, red dot is the poppet cam axle, blue dot the air hose, green dot where the diaphragm is (on the inside)

Diagram of the governor

Diagram of the governor

8 = control rod

10 = diaphragm

13 = spring

15a 15b = poppet cam

If there is an air leakage, for instance a loose air hose, torn diaphragm, leaking axle of the poppet cam, the idle will be high, because there will not be enough vacuum to pull back the diaphragm, and because the air valve will be closed, there will not be enough air to burn all the diesel, so that the engine smokes.

So you must determine where the air leak is. If you read this topic:

White Smoke 220D - Benzworld.org - Mercedes-Benz Discussion Forum

you can find out how the system works and how to diagnose it. After that you only have to find the parts...

{end quote}

Source:

1973 220D W115 Injection Pump Gasket - Benzworld.org - Mercedes-Benz Discussion Forum

Here you can see the diaphragm (on a slightly older MB diesel engine) when the rest of the governor is removed:

The spring presses against the middle part, the leathery part can tear.