|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

LinkBack | Thread Tools | Display Modes |

|

|

|

#1

|

|||

|

|||

|

Interesting thoughts.

I also feel that residual rubber particles remaining in the pump body from the deterioated o-rings is a contributing factor. You can have everything sparkling clean before removal and rinse the valve holder numerous times before reinstalling but will still have contaminated fuel that remains inside the lower portion of the valve. When restarted those particles end up at the inj. Iin an attempt to avoid this I've suggested more recently that once the DV's are back together a few ounces of fuel be pumped out before the hard lines are reconnected to the inj's.

__________________

Terry Allison N. Calif. & Boca Chica, Panama 09' E320 Bluetec 77k (USA) 09' Hyundai Santa Fe Diesel 48k (S.A.) |

|

#2

|

|||

|

|||

|

Does anyone really know what the function of the copper crush washer is? It appears to me that it doesn't really get crushed, so calling it a crush washer may be incorrect. It seems more to act as a "bearing" surface between the spring and the DV plunger part. I've always questioned the necessity of replacing the washer since, as I said, it never gets crushed and don't think it will even wear out. I don't even see it pictured in that drawing in post #1 of this thread. I wonder what would happen if it was left out completely?

I always assumed it allowed the plunger piece to rotate if it wanted to since having it be between the bottom of the spring and the top of the plunger allows the plunger to slide against the washer instead of the bottom of the spring - where it could get snagged on the end of the spring wire or the spring itself could wear into the top of the plunger piece if they were in constant contact with one another. I'd love to know if someone actually knows the exact purpose of that copper washer in there.

__________________

Marty D. 2013 C300 4Matic 1984 BMW 733i 2013 Lincoln MKz |

|

#3

|

||||

|

||||

|

Quote:

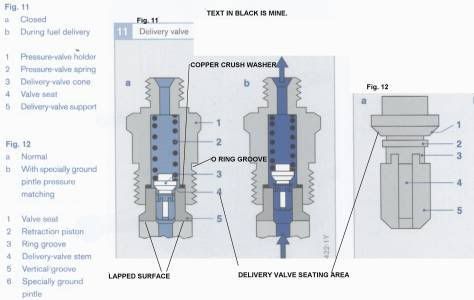

(Please see FIG-11 only)-The purpose of the Copper Crush washer is to provide a seal between the top of the Delivery Valve Support-item 5 and the Pressure Valve Holder- item 1. The Copper Crush washer is exposed to the same pressure as the injectors and in fact it is possible for the high pressure to erode the crush washer. The reason the Crush Washers need to be changed is that in order form a seal the copper compresses conforming to any irregularities between the Pressure Valve Holder and the top of the Delivery Valve Support. Ounce used the Crush Washer is in a sense deformed to fit; and also when squashed down during the torque procedure the Crush Washer becomes work hardened and is no longer as soft as before (meaning if you use it again it may not seal well). Also I believe that the Crush Washers are some stiffer alloy that is not as soft to begin with as stay the copper washers on your fuel filter banjos. (If you heat these red hot and let them cool they become soft again and can be reused.) Back to the picture- There are the words “Lapped Surface” with 2 lines pointing to where the lapped surface is. Below that parting line is where the Plunger and Barrel Assembly; the plunger part of this is the part that rotates. Also the Lapped Surface area if lapped properly dose not need any sort of seal do to a precision fit between the bottom of the Delivery Valve Support and the top of the Plunger and Barrel. Item number 3 the Delivery Valve Cone; the part that we call the delivery valve dose not rotate it just goes up and down.

__________________

84 300D, 82 Volvo 244Gl Diesel |

|

#4

|

||||

|

||||

|

Quote:

__________________

84 300D, 82 Volvo 244Gl Diesel |

|

#5

|

|||

|

|||

|

OK, I see now what the crush washers do, thanks. Looking at the photos in this wiki again helped refresh my memory:

http://www.peachparts.com/Wikka/OM606DeliveryValveSeals My problem was I didn't see how the crush washer got centered over the plunger part when you screwed the DV cover on but it looks like it is tapered some to help. I wonder if some people who have terrible troubles after doing the job muck up the centering of the copper washer and that's what causes poor running since that might interfere with the operation of the plunger part?

__________________

Marty D. 2013 C300 4Matic 1984 BMW 733i 2013 Lincoln MKz |

|

#6

|

||||

|

||||

|

Quote:

__________________

84 300D, 82 Volvo 244Gl Diesel |

|

#7

|

|||

|

|||

|

On my '87 I put the washer in the pressure valve holder with a drop of diesel to hold it in for assembly. The PV holder has a collar inside that the crush washer sits on so it's almost impossible for it not to center properly if you assemble it that way.

__________________

LRG 1987 300D Turbo 175K 2006 Toyota Prius, efficent but no soul 1985 300 TDT(130K miles of trouble free motoring)now sold |

|

| Bookmarks |

|

|