|

|

|

|

|

|

|

|

|

|

|

|

|

#1

|

|||

|

|||

|

Injection pump - no fuel 1 valve

99 E300 Turbo Diesel, 152000

Hello diesel friends! I don't have any fuel coming out of the delivery valve closest to the bumper. Odd thing is when I loosen the valve, I get plenty of fuel squirting out. Whenever I tighten the valve back down (35nm) nothing. I tried this several times - same result. This comes after I had the delivery valves apart to replace the O-rings & crush washers. The pressure valve carrier & the piston came out when I pulled out the pressure valve holder - but I'm pretty sure I put everything back in correctly. I checked it against another valve. I checked all other valves- they are working correctly. I get plenty of fuel out of every line except the 1st one. Any help appreciated!! Thanks - Tim |

|

#2

|

||||

|

||||

|

It's coming out of the line, but not the injector? Sounds like an injector problem.

__________________

Michael LaFleur '05 E320 CDI - 86,000 miles '86 300SDL - 360,000 miles '85 300SD - 150,000 miles (sold) '89 190D - 120,000 miles (sold) '85 300SD - 317,000 miles (sold) '98 ML320 - 270,000 miles (sold) '75 300D - 170,000 miles (sold) '83 Harley Davidson FLTC (Broken again) :-( '61 Plymouth Valiant - 60k mikes 2004 Papillon (Oliver) 2005 Tzitzu (Griffon) 2009 Welsh Corgi (Buba)

|

|

#3

|

|||

|

|||

|

injection pump

Actually the fuel is not getting to the injector, it's not coming out at the delivery valve (except when I loosen the valve) Thanks - Tim

|

|

#4

|

|||

|

|||

|

You probably removed more than just the pressure valve holder, spring and crush washer and havn't gotten the other parts back in correctly.

How many parts did you remove? Here's the detail to refer to. http://www.peachparts.com/shopforum/showthread.php?t=173991 Your best bet is to remove #1 frist, then #2 and copy #2 being VERY careful to note EXACTLY how everything you removed originally from #1 comes out of #2. Go no further down into #2 than you did on #1 the first time. If that doesnt work the pump may need to be recalibrated on a Bocsh flow bench.

__________________

Terry Allison N. Calif. & Boca Chica, Panama 09' E320 Bluetec 77k (USA) 09' Hyundai Santa Fe Diesel 48k (S.A.) Last edited by TMAllison; 01-26-2009 at 11:44 PM. |

|

#5

|

||||

|

||||

|

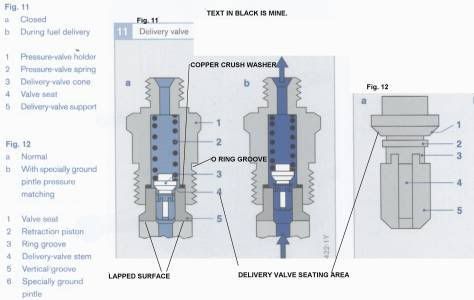

Does this look like the same Delivery Valve setup that you have or was there more than just the Pressure Valve Spring up inside of your Delivery Valve Holder? (Some IPs have another type of Pressure Valve Spring and even another type of Valve up inside of the Delivery/Pressure Valve Holder.)

And which of the above parts were removed when you did the O-ring replacement?

__________________

84 300D, 82 Volvo 244Gl Diesel |

|

#6

|

|||

|

|||

|

Diagram of Delivery valve

My delivery valve looks just like the one in the attached diagram. All the parts shown came out along with the piston below it. The piston has 2 holes in it on the sides, small hole in front, small hole in back. I checked another delivery valve to determine where which way it lined up. - Tim

|

|

#7

|

|||

|

|||

|

Piston = 7k Valve Element?

7G below it is the one that needs to be observed if it was distrubed. There is a tab on it which if misaligned can break off or deform the insides when torqued.

__________________

Terry Allison N. Calif. & Boca Chica, Panama 09' E320 Bluetec 77k (USA) 09' Hyundai Santa Fe Diesel 48k (S.A.) |

|

#8

|

|||

|

|||

|

Quote:

I'm going to take it apart again tomorrow and photograph everything. I really appreciate the input & assistance! - Tim |

|

#9

|

||||

|

||||

|

I got your PM however I am still not clear as to what was removed.

Item 7g in the pdf you posted only goes 1 direction and item 7k is match to it; they are a set. Take a good look at the parts. The end where 7k fits is supposed to go into is ground to the same angle as the fat part of 7k. Look at the 3rd diagram at the below site to the left of the page is an exploded view of the Delivery Valve holder and parts on down below. Item 7g in your pdf is Item 107 in that diagram. http://www.detali.ru/cat/oem_mb2.asp?TP=1&F=210020&M=606%2E912&GA=722%2E438722%2E600&GM=717%2E446&CT=M&cat=19T&SID=07&SGR=045&SGN=01 Between Item 107 and Item 113 is a part with no Item number. This part is the IP Element/Plunger and Barrel Assembly. The IP Element is an assembly of 2 pieces. The upper part (the barrel) is where the bottom of Item 7g(107) seats. You can see the top of it when you remove everthing from Item 7g on up. What you cannot see is that on the side of the Barrel is a slot. The slot is supposed to line up with a Pin inside of the IP housing. Sometimes when you pull up on Item 7g they stick together and you pull up the IP Element/Barrel enough for the slot and pin not to be in alignment. Also if they are out of alignment and you torque them down it is possible to distort the IP housing and even shear off the alignment pin.

__________________

84 300D, 82 Volvo 244Gl Diesel |

|

#10

|

||||

|

||||

|

Here is a pic of a generic IP Element/Plunger and Barrel Assembly. The slot is supposed to align with a pin in the IP housing. [This is the part TMAlison was speaking of.]

__________________

84 300D, 82 Volvo 244Gl Diesel |

|

#11

|

|||

|

|||

|

The issue was that the slot on the barrel in this diagram was not aligning correctly (even though I thought it was). I was using the holes at the top of the barrel to align it - compared to the other injectors. This time, I just kept spinning the barrel until I could feel it lock in. I now have fuel to all 6 injectors! I haven't test driven it yet, but hopefully the issue is resolved. I can't thank everyone enough for helping me out on this. THANKS SO MUCH. - Tim

|

|

#12

|

|||

|

|||

|

Parrot of Doom posted a DIY that goes into great detail regarding the delivery valves. The section that really caught my eye was the part about wiggling the delivery valve as you screw it in by hand. He states that by doing this, you allow all the parts inside to orient themselves correctly before torquing them down.

http://www.peachparts.com/shopforum/showthread.php?t=211801

__________________

96 E300d |

|

#13

|

|||

|

|||

|

If it was me this happened to I would do exactly what you are doing...go back, take it apart again, confirm everything is the way it is supposed to be, use new crush washer and o-ring and re-assemble it. Sometimes that is all it takes to fix the problem. Let us know how it turns out in the end, good luck.

__________________

Marty D. 2013 C300 4Matic 1984 BMW 733i 2013 Lincoln MKz |

|

#14

|

|||

|

|||

|

Hi, I've been having the EXACT problem on my 1987 W201 OM602, cylinder 1 also. I did not intentionally move or molest the barrel, but perhaps I did. I'd like to remove it to inspect it and make sure I replace it properly. How does one remove the barrel? Thanks!

|

|

#15

|

||||

|

||||

|

Quote:

The Author of the thread will have to tell you how he did it. However, if it is at all possible do not pull the Barrel completely off of the plunger (if pissible rotate it slowly until the slot in the Barrel pops back over the pin in the IP housing). If you do end up pulling it up; pull it out slowly so that the plunger has time to remain where it is (it will stick to the Barrel a little but will drop down on its own weight if you give it time to) and pull it up only enought to get the slot and pin lined up. When I worked in a shop on IPs I had a large tweezers with a 45 degree bend that would work to grab some of the barrels; but different pumps have different amounts of room so I cannot say the same will work with these IPs. I also sometimes used a medical type Forcepts again with a 45 degree bend. However, you need to be careful as the Forcepts is made of harder metal with sharp teeth and you do not want to scratch or burr any of the mating survaces.

__________________

84 300D, 82 Volvo 244Gl Diesel |

|

| Bookmarks |

|

|